PP/ABS alloy material with high thermal ageing resistance, and preparation method of material

An alloy material, high heat-resistant technology, applied in the field of high heat-resistant aging PP/ABS alloy material and its preparation, to achieve the effect of convenient operation, lower production cost, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

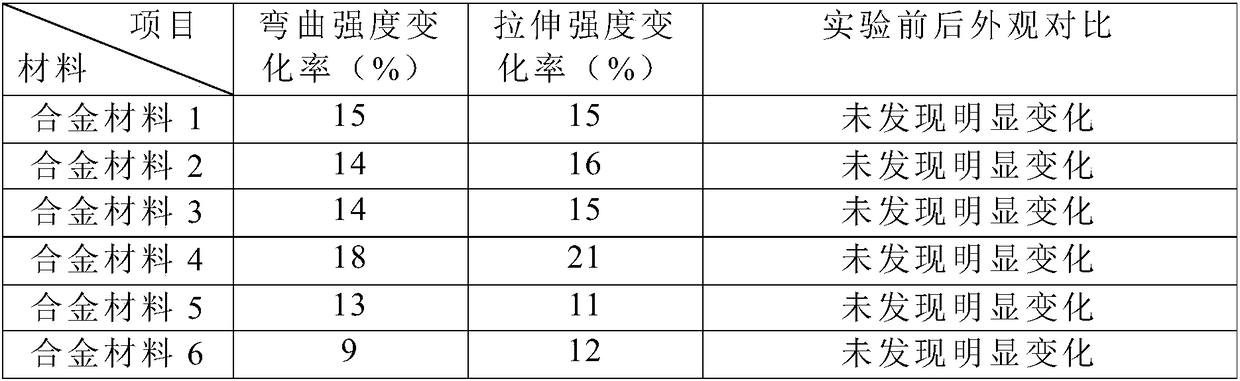

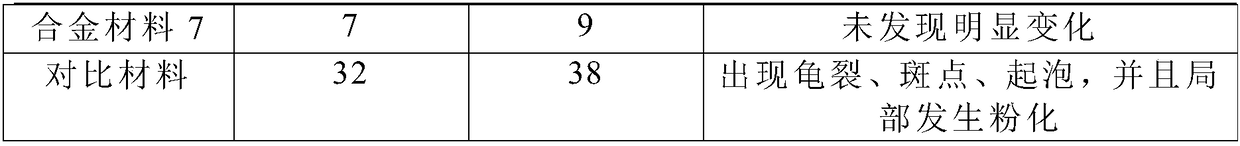

Examples

Embodiment 1

[0033] This embodiment provides a PP / ABS alloy material with high heat aging resistance. Specifically, the PP / ABS alloy material with high heat aging resistance includes 60 parts by mass of PP resin, 40 parts of ABS resin, 5 parts by mass. parts of compatibilizer, 0.1 parts of antioxidant, 10 parts of glass fiber and 40 parts of filler.

[0034] Wherein, the compatibilizer is a matrix resin with PP resin, a maleic anhydride graft copolymer with a maleic anhydride graft rate of 1.0%, and the antioxidant includes a main antioxidant and an auxiliary antioxidant, and the main antioxidant is The N,N'-diisobutyl-p-phenylenediamine of 0.06 parts by mass, the auxiliary antioxidant is tetrakis(4-methoxyhexalkoxy-4,4'- Biphenyl) bisphosphonate, filler is nanometer calcium carbonate.

[0035] PP resin is a non-polar resin, while ABS resin is a polar resin, so if the two resins are directly blended, the uniformity of the obtained alloy material is not satisfactory, and even delamination ...

Embodiment 2

[0052] This embodiment provides a PP / ABS alloy material with high heat aging resistance. Specifically, the PP / ABS alloy material with high heat aging resistance includes 40 parts by mass of PP resin, 60 parts of ABS resin, 15 parts by mass. 1 part of compatibilizer, 1 part of antioxidant, 20 parts of glass fiber and 20 parts of filler.

[0053] Wherein, the compatibilizer is a matrix resin with POE resin, a maleic anhydride graft copolymer with a maleic anhydride graft rate of 1.4%, and the antioxidant includes a main antioxidant and an auxiliary antioxidant, and the main antioxidant is 0.6 parts by mass of N, N'-diisobutyl-p-phenylenediamine, and the auxiliary antioxidant is tetrakis(4-methoxyhexalkoxy-4,4'- Biphenyl) bisphosphonate, the filler is nanometer barium sulfate.

[0054] As antioxidant N, the specific synthetic steps of N'-diisobutyl-p-phenylenediamine and tetrakis (4-methoxyhexalkoxy-4,4'-biphenyl) diphosphonate are all related to It is completely the same as th...

Embodiment 3

[0058] This embodiment provides a PP / ABS alloy material with high heat aging resistance. Specifically, the PP / ABS alloy material with high heat aging resistance includes 50 parts by mass of PP resin, 50 parts of ABS resin, 10 parts by mass. Parts of compatibilizer, 0.5 parts of antioxidant, 15 parts of glass fiber and 30 parts of filler.

[0059] Wherein, the compatibilizer is a matrix resin with PP resin, a maleic anhydride graft copolymer with a maleic anhydride graft rate of 1.2%, and the antioxidant includes a main antioxidant and an auxiliary antioxidant, and the main antioxidant is The N,N'-diisobutyl-p-phenylenediamine of 0.3 parts by mass, the auxiliary antioxidant is tetrakis(4-methoxyhexalkoxy-4,4'- Biphenyl) bisphosphonate, filler is nanometer calcium carbonate.

[0060] As antioxidant N, the specific synthetic steps of N'-diisobutyl-p-phenylenediamine and tetrakis (4-methoxyhexalkoxy-4,4'-biphenyl) diphosphonate are all related to It is completely the same as tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com