A kind of purification method of artificial diamond

A technology of artificial diamond and artificial diamond powder, applied in diamond and other directions, can solve problems such as incomplete oxidation of residual graphite, and achieve the effects of improved working environment, good wave transmission performance and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The purification method of the artificial diamond of the present embodiment may further comprise the steps:

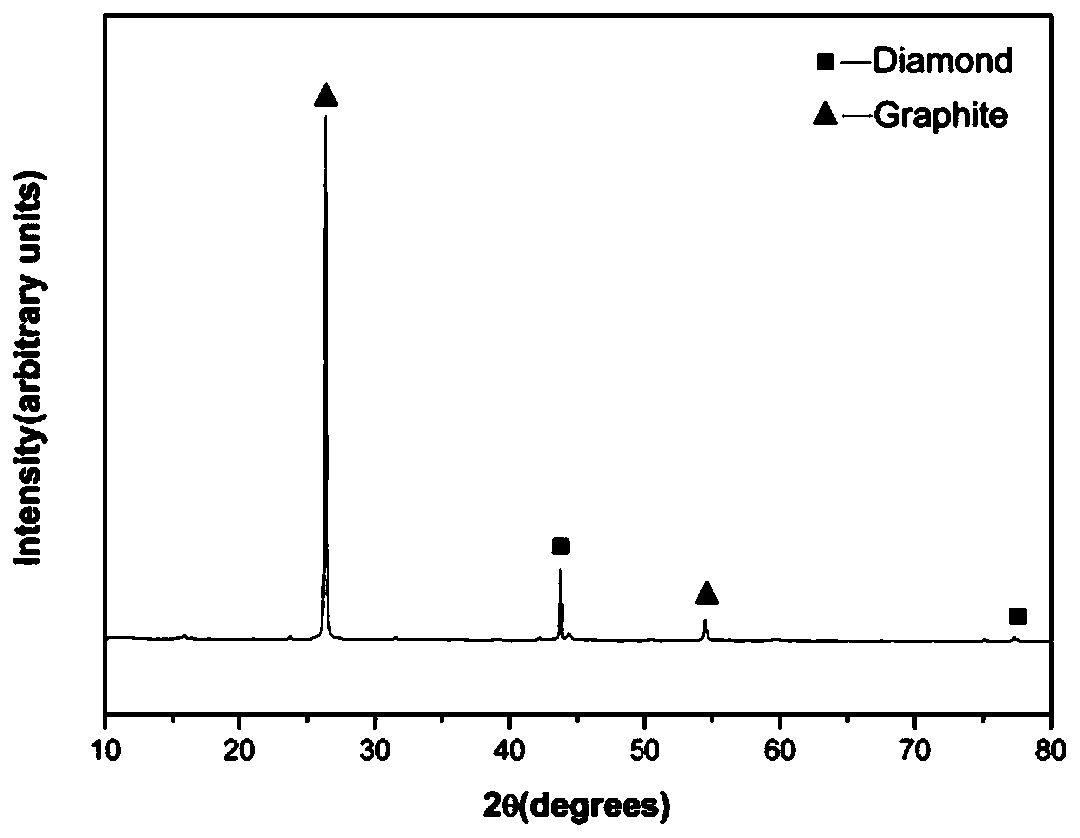

[0043] 1) The artificial diamond synthetic rod synthesized by the high temperature and high pressure method is mechanically crushed, sieved, and the artificial diamond synthetic rod powder is obtained, the particle size is below 1mm, and its X-ray diffraction analysis is as follows: figure 1 shown by figure 1It can be seen that the synthetic diamond synthetic rod powder contains more non-diamond carbon;

[0044] 2) Put 200g of synthetic diamond rod powder in the crucible, then place the crucible in a dual-frequency microwave sintering equipment, and carry out microwave heating treatment for 90 minutes in a flowing air atmosphere. The dual-frequency is 915MHz and 2450MHz simultaneously, and the heating temperature is at 550°C to obtain pretreated synthetic diamond mixed powder;

[0045] 3) The pretreated artificial diamond mixed powder is crushed by ball millin...

Embodiment 2

[0048] The purification method of the artificial diamond of the present embodiment may further comprise the steps:

[0049] 1) mechanically crushing the synthetic diamond rod, and sieving to obtain synthetic diamond synthetic rod powder, the particle size of which is below 1 mm;

[0050] 2) Put 200g of synthetic diamond synthetic rod powder in a crucible, then place the crucible in a dual-frequency microwave sintering equipment, and carry out microwave heating treatment for 60 minutes under a flowing air atmosphere, and the dual frequency is 915MHz and 2450MHz simultaneously, and the heating temperature is 600°C, to obtain pretreated synthetic diamond mixed powder;

[0051] 3) crushing the pretreated artificial diamond mixed powder by ball milling in water, and separating the magnetic metal catalyst from the diamond particles by magnetic separation;

[0052] 4) Place the diamond particles separated in step 3) in a crucible, and then add a surfactant, which is mixed with water...

Embodiment 3

[0054] The purification method of the artificial diamond of the present embodiment may further comprise the steps:

[0055] 1) mechanically crushing the synthetic diamond rod, and sieving to obtain synthetic diamond synthetic rod powder, the particle size of which is below 1 mm;

[0056] 2) Put 200g of synthetic diamond synthetic rod powder in the crucible, then place the crucible in a dual-frequency microwave sintering equipment, and carry out microwave heating treatment for 120min under a flowing air atmosphere. The dual-frequency is 915MHz and 2450MHz simultaneously, and the heating temperature is 400°C, to obtain pretreated synthetic diamond mixed powder;

[0057] 3) crushing the pretreated artificial diamond powder by ball milling in water, and separating the magnetic metal catalyst from the diamond particles by magnetic separation;

[0058] 4) Place the diamond particles separated in step 3) in a crucible, then add a surfactant with a volume fraction of 3% hydrogen pero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com