Composite high-temperature proton exchange membrane as well as preparation and application thereof

A proton exchange membrane and composite membrane technology, applied in the field of high temperature fuel cell composite proton exchange membrane and its preparation, can solve the problems of poor mechanical properties, loss of phosphoric acid, etc., and achieve the effects of excellent comprehensive performance, good dispersibility and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

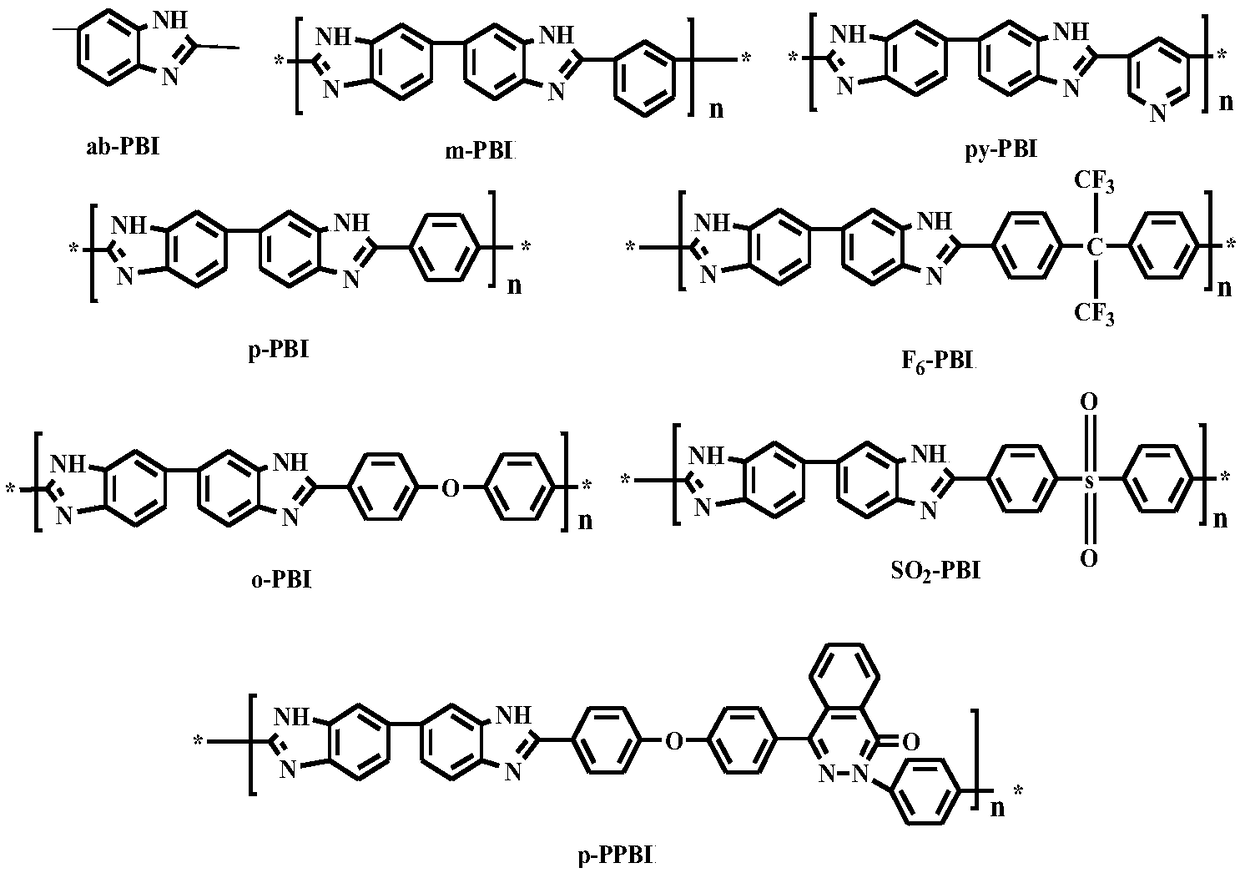

Method used

Image

Examples

Embodiment 1

[0029] Take 20g of poly(2,2'-(m-phenyl)-5,5'-bibendazole) (mPBI) and add 180g of N,N-dimethylacetamide, stir at room temperature for 24h to form a solid content 10 wt% mPBI solution. Weigh 30g of mPBI solution (10wt% solid content), pour the solution onto a glass plate, cast it on a glass plate and dry it thoroughly in an oven at 80°C, continue heating at 150°C for 5 hours, and finally remove it from the glass plate to obtain a PBI film.

[0030] Take a 4*4cm PBI membrane and soak it in 85wt% phosphoric acid solution, soak it at 80°C for 24 hours, remove excess phosphoric acid on the surface with filter paper, and obtain undoped acid-modified ordered mesoporous SiO 2 Phosphoric acid doped composite film (PA / PBI) quality, the phosphoric acid doping level is 10.0.

Embodiment 2

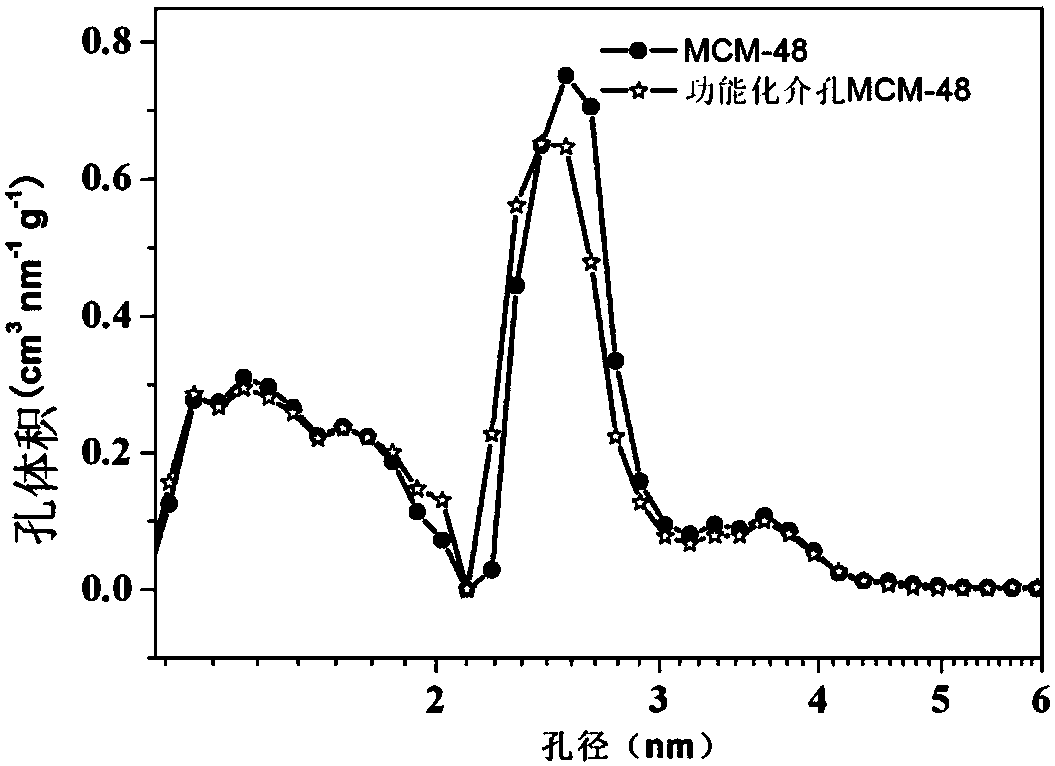

[0032] (1) Add 15ml of 85wt% phosphoric acid, 50ml of deionized water and 3.0MCM-48 into the one-mouth bottle successively, put it in a decompression device, and let it stand at -0.1MPa for 0.5 hours, then install a condensation reflux device on the one-mouth bottle, 80°C, constant temperature under normal pressure, react for 24h, use Buchner funnel to separate the prepared solid powder from the solvent, and wash the solid powder repeatedly with ethanol, collect and dry in a vacuum oven at 120°C for 12h to prepare acid-modified ordered Mesoporous SiO 2 , that is, phosphorylated functionalized MCM-48 (PA-MCM).

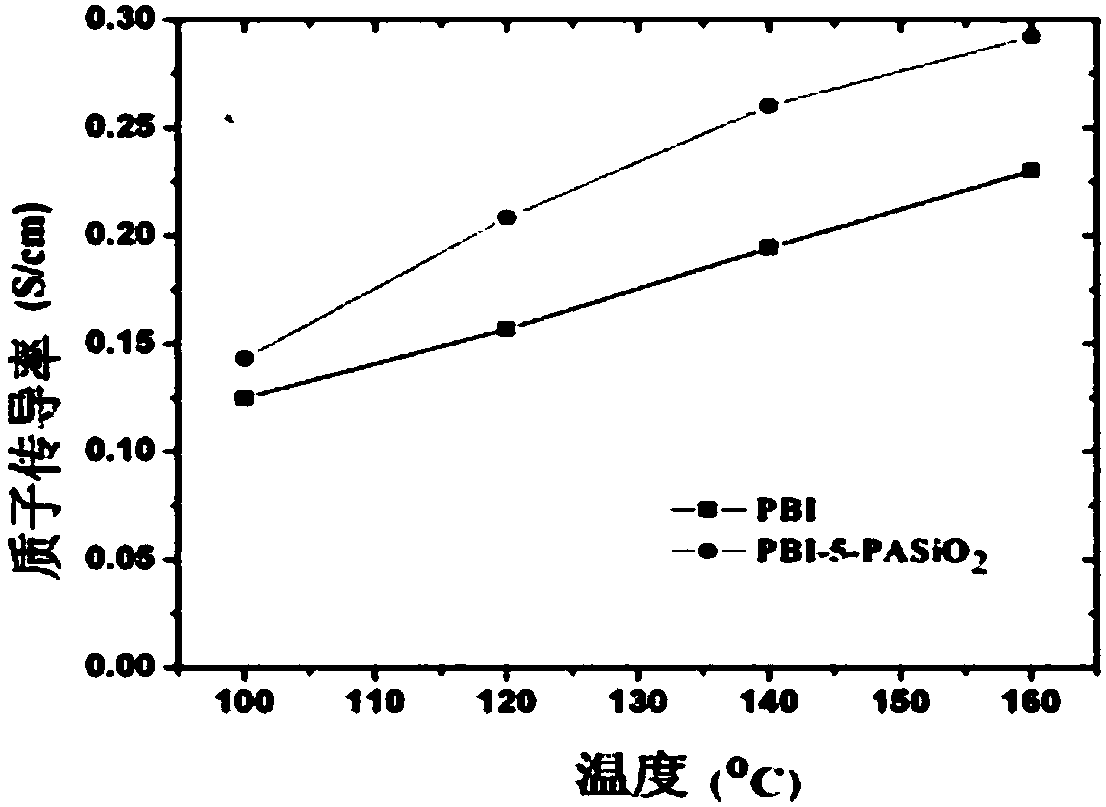

[0033] Weigh 28.5g of mPBI solution (10wt% solid content), add 0.15g PA-MCM to it, pour the solution on a glass plate, cast it and dry it thoroughly in an oven at 80°C, continue heating at 150°C for 5h, and finally remove it from the glass Take off the plate to obtain PBI-SiO with a mass fraction of 5% in the composite film of phosphoric acid modified MCM-48 2 Composi...

Embodiment 3

[0036] Adopt and embodiment 2 to prepare PA / PBI-5-PASiO 2 The same method was used to prepare phosphoric acid modified MCM-48 in PBI-SiO 2 Phosphoric acid doped high temperature proton exchange membrane (PA / PBI-20-PASiO 2 ), the difference is that the quality of PA-MCM is increased to 0.6g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com