Rapid manufacturing method of enhancement type conformal cooling die copper

A technology of conformal cooling and manufacturing method, which is applied in the field of rapid manufacturing of enhanced conformal cooling mold copper, can solve the problems of low material utilization rate, reduced enhancement effect, uneven distribution of ceramic phases, etc., and achieve improved laser absorption rate, Good dispersion strengthening effect, saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

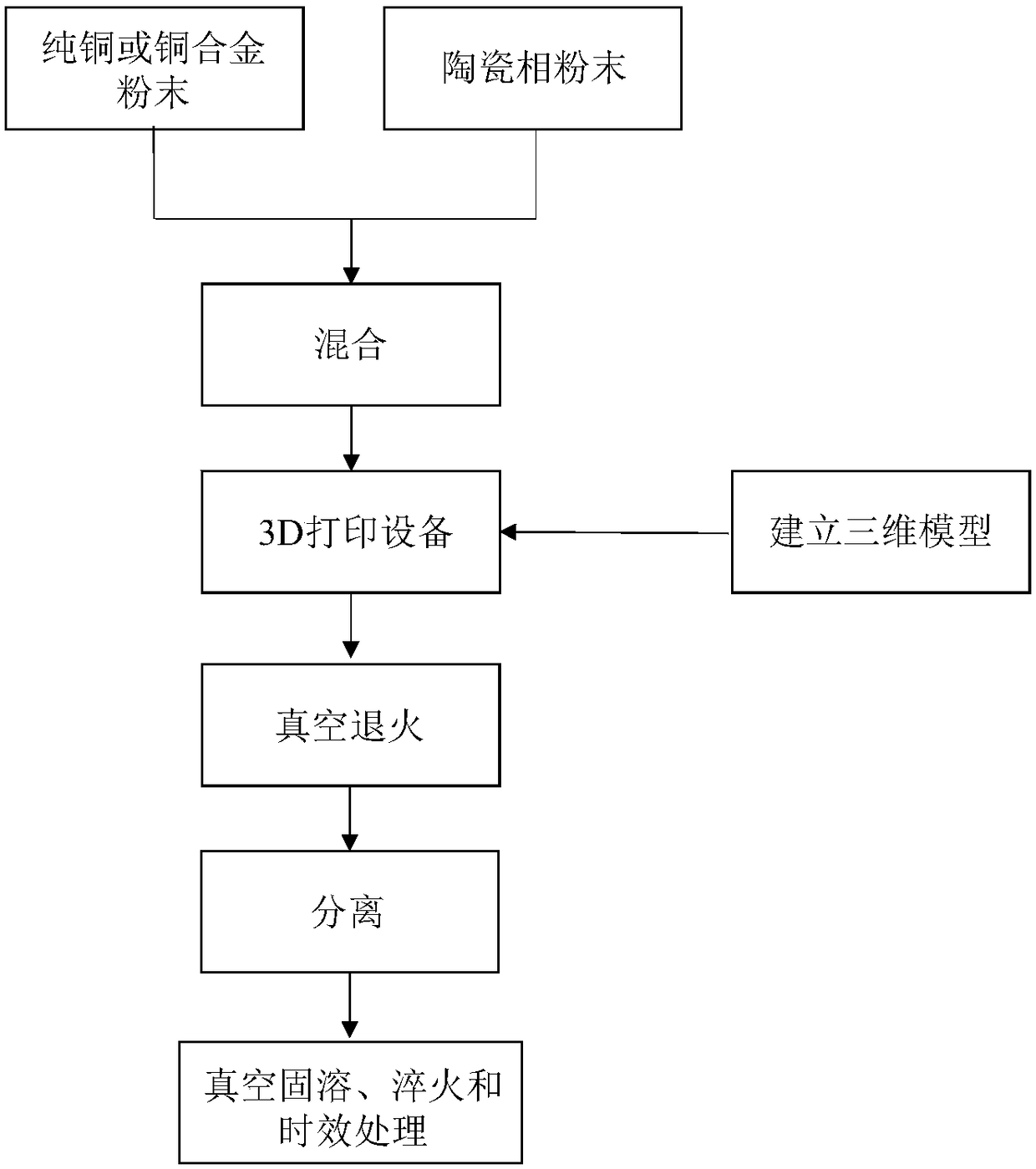

Method used

Image

Examples

Embodiment 1

[0038] First, establish a three-dimensional model of the mold, and then process the model into layered slices and import it into the 3D printing device.

[0039] Next, weigh 2.0 Kg of pure copper powder, wherein the pure copper powder is spherical or nearly spherical, the powder particle size distribution is between 15 μm and 50 μm, and the oxygen content is lower than 1000 ppm; 0.2 Kg of TiN powder with a purity of more than 99.9% is weighed, The particle size of the powder is distributed between 50nm and 1μm. Mechanical grinding is carried out by means of a ball mill in an inert atmosphere.

[0040] Next, fix the substrate horizontally in the molding cylinder, dry the mixed powder in a vacuum oven for 6 hours, and then send it to the feeding device of the laser selective melting equipment, and then pass in argon protective gas to preheat the substrate.

[0041] Next, the laser source is Yb fiber laser, the wavelength is 1070±10nm, and the spot diameter is 0.13mm; the laser ...

Embodiment 2

[0045] First, establish a three-dimensional model of the mold, then process the model in layers and slice it, and import it into the 3D printing device.

[0046] Next, weigh 2.2Kg of beryllium bronze alloy powder, wherein the pure copper powder is spherical or nearly spherical, the powder particle size distribution is between 15μm and 45μm, and the oxygen content is lower than 1000ppm; weigh 0.1Kg of TiC powder with a purity of more than 99.95%. , The particle size distribution of the powder is between 50nm and 1μm. Mechanical grinding is carried out by means of a ball mill in an inert atmosphere.

[0047] Next, fix the substrate horizontally in the molding cylinder, dry the mixed powder in a vacuum oven for 6 hours, and then send it to the feeding device of the laser selective melting equipment, and then pass in argon protective gas to preheat the substrate.

[0048] Next, the laser source is Yb fiber laser, the wavelength is 1070±10nm, and the spot diameter is 0.13mm; the l...

Embodiment 3

[0052] First, establish a three-dimensional model of the mold, then perform layered slice processing, and import it into the 3D printing device.

[0053] Next, weigh 19.8Kg of tin-bronze alloy powder, wherein the pure copper powder is spherical or nearly spherical, the final particle size distribution is between 20μm and 50μm, and the oxygen content is lower than 1000ppm; 0.2Kg of TiB with a purity of more than 99.99% is weighed 2 Powder, powder particle size distribution in 50nm ~ 1μm. Mechanical grinding is carried out by means of a ball mill in an inert atmosphere.

[0054] Next, fix the substrate horizontally in the molding cylinder, dry the mixed powder in a vacuum oven for 6 hours, and then send it to the feeding device of the laser selective melting equipment, and then pass in argon protective gas to preheat the substrate.

[0055] Next, the laser source is a Yb fiber laser with a wavelength of 1070±10 nm and a spot diameter of 0.15 mm. The laser power is 300W, the sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com