Preparation method of lightweight high-strength heat-insulating mullite fiber porous ceramic

A mullite fiber and porous ceramic technology, which is applied in the field of fiber porous ceramics, can solve the problems of poor mechanical properties and uneven distribution of binders, achieve uniform distribution, improve dispersion and suspension characteristics, and improve the effect of firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

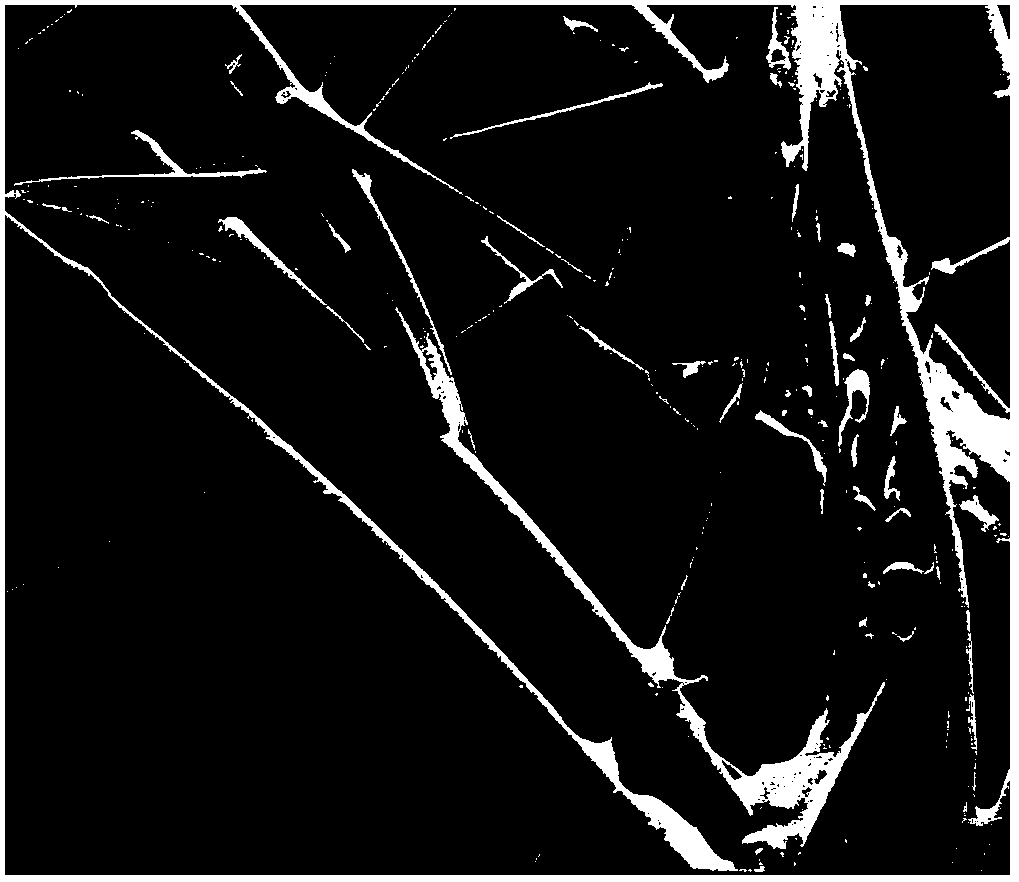

Image

Examples

Embodiment 1

[0030] In this embodiment, a method for preparing a light-weight, high-strength heat-insulating mullite fiber porous ceramic is specifically carried out according to the following steps:

[0031] (1) 0.27g polyacrylamide, 0.3g boron carbide powder, 8ml silica sol (the density of silica sol used is 1.25g / cm 3 , the same below), mixed with 90ml of deionized water, stirred with a stirrer for 10 minutes until the mixture was uniform, put it into a planetary ball mill for ball milling for 8 hours, and obtained a uniformly mixed binder slurry;

[0032] (2) Weigh 6.32g of chopped polycrystalline mullite fibers with a diameter of 8μm and a length of 400μm and add them to 100ml of the binder slurry obtained in step (1), stir with a stirrer while adding, and wait for the fibers to be added Continue to stir for 15 minutes until the fibers are evenly dispersed in the binder slurry to obtain a well-dispersed fiber slurry;

[0033] (3) Pour the fiber slurry obtained in step (2) into a mold...

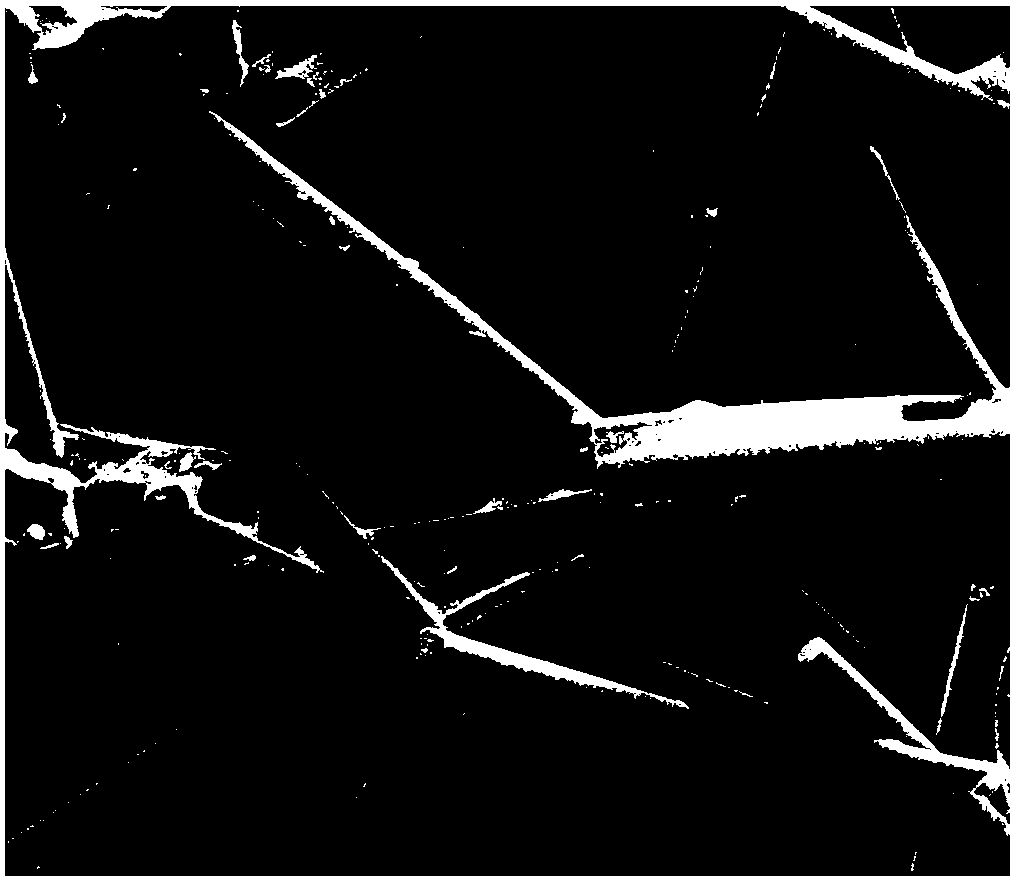

Embodiment 2

[0037] In this embodiment, a method for preparing a light-weight, high-strength heat-insulating mullite fiber porous ceramic is specifically carried out according to the following steps:

[0038] (1) Mix 0.3g polyacrylamide, 0.5g boron carbide powder, 8ml silica sol, and 90ml deionized water, stir with a stirrer for 15 minutes until the mixture is uniform, put it into a planetary ball mill for ball milling for 9 hours, and obtain a uniformly mixed binder slurry;

[0039](2) Weigh 6.32g of chopped mullite fibers with a diameter of 10μm and a length of 500μm and add them to 100ml of the binder slurry obtained in step (1), stir with a stirrer while adding them, and wait until the fibers are added Continue to stir for 20 minutes until the fibers are evenly dispersed in the binder slurry to obtain a well-dispersed fiber slurry;

[0040] (3) Pour the fiber slurry obtained in step (2) into a mold with a filter screen at the lower end, turn on the vacuum pump, and set the suction fil...

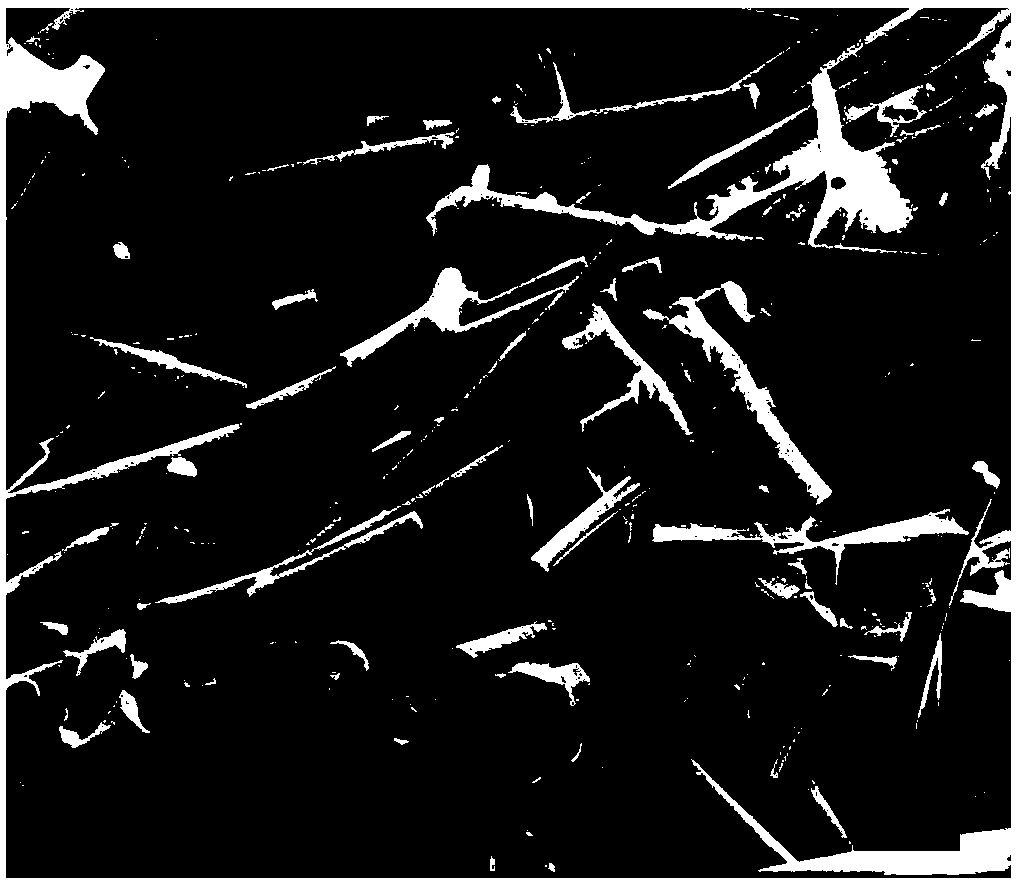

Embodiment 3

[0044] In this embodiment, a method for preparing a light-weight, high-strength heat-insulating mullite fiber porous ceramic is specifically carried out according to the following steps:

[0045] (1) Mix 0.5g polyacrylamide, 0.5g boron carbide powder, 8ml silica sol, and 90ml deionized water, stir with a stirrer for 20 minutes until the mixture is uniform, put it into a planetary ball mill for ball milling for 12 hours, and obtain a uniformly mixed binder slurry;

[0046] (2) Weigh 10 g of chopped polycrystalline mullite fibers with a diameter of 10 μm and a length of 600 μm and add them to the binder slurry obtained in step (1), stir with a stirrer while adding them, and wait until the fibers are added Continue to stir for 25 minutes until the fibers are evenly dispersed in the binder slurry to obtain a well-dispersed fiber slurry;

[0047] (3) Pour the fiber slurry obtained in step (2) into a mold with a filter screen at the lower end, turn on the vacuum pump, set the sucti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com