Anti-ablation rubber composition used as anti-ablation protective coating in aluminum alloy products, aluminum alloy products and preparation method thereof

A rubber composition and protective coating technology are applied in the field of anti-ablation protection of aluminum alloys, and can solve the problems of thin-walled aluminum alloy closing cylinder body ablation, unsolved problems, failure of anti-ablation protection, and the like. Achieve the effect of low cost, long service life and strong ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

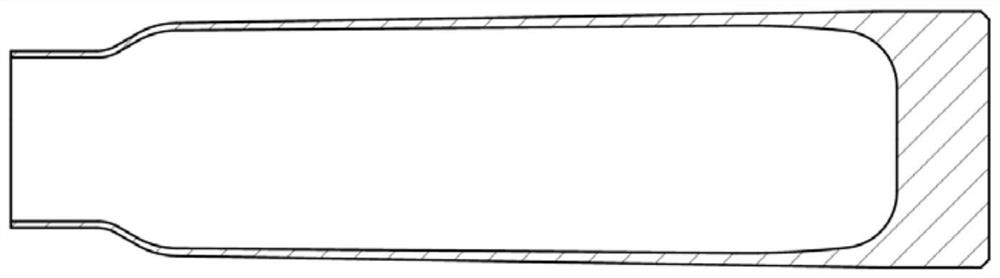

[0091] In a third aspect, in at least one embodiment, a method for preparing an aluminum alloy product is provided, comprising the following steps:

[0092] The anti-ablative rubber composition is first kneaded and then extruded into a thin sleeve through an extruder;

[0093] The thin sleeve is then tightly attached to the inner wall of the cylinder body by means of air bag pressurization to obtain an aluminum alloy product with an anti-ablation protective coating closely attached to the cylinder body.

[0094] In the present invention, the silicone rubber is firstly mixed, then extruded into a thin sleeve through an extruder, and then directly bonded and vulcanized on the inner wall of the thin-walled aluminum alloy closing cylinder by using an air bag to pressurize, and finally obtain a thin-walled aluminum alloy closing Anti-ablation protective rubber layer closely fitted to the barrel. The method is simple, efficient, easy to operate, and easy to control the process. Thi...

Embodiment 1

[0115] An aluminum alloy product, comprising a barrel body and an anti-ablation protective coating attached to the inner surface of the barrel body; the anti-ablation protective coating is mainly made of an anti-ablation rubber composition;

[0116] In terms of parts by mass, the anti-ablation rubber composition is mainly prepared from the following raw materials: 100 parts of methyl vinyl silicone rubber, 6 parts of diphenylsilanediol, 60 parts of white carbon black, 0.5 parts of titanium dioxide and diphenyl peroxide Formyl 1.5 parts.

[0117] The preparation method of the aluminum alloy product comprises the following steps:

[0118] (a) Silicone rubber mixing

[0119] Mix the silicone rubber on a two-roller mixer, the temperature of the rollers is controlled at 50-60°C, the mixing time is 20-30min, and the roller speed is 16r / min;

[0120] ① Wrap 100 parts of methyl vinyl silicone rubber raw rubber;

[0121] ② Add 6 parts of structural control agent diphenylsilanediol; ...

Embodiment 2

[0144] An aluminum alloy product, comprising a barrel body and an anti-ablation protective coating attached to the inner surface of the barrel body; the anti-ablation protective coating is mainly made of an anti-ablation rubber composition;

[0145] In terms of parts by mass, the anti-ablation rubber composition is mainly prepared from the following raw materials: 100 parts of methyl vinyl phenyl silicone rubber, 20 parts of diatomaceous earth, 2 parts of hydroxyl silicone oil, 5 parts of aluminum hydroxide, and 2 parts of chrome green And 3 parts of dicumyl peroxide.

[0146] The preparation method of the aluminum alloy product comprises the following steps:

[0147] (a) Silicone rubber mixing

[0148]Mix the silicone rubber on the kneader, the mixing time is 20-30min, and the paddle speed is 40r / min, 26r / min;

[0149] ① Put 100 parts of raw methyl vinyl phenyl silicone rubber into the kneader;

[0150] ② Add 20 parts of diatomaceous earth as a reinforcing filler;

[0151...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com