A preparation method and application of a reproducible PDMS-based microsoft Ag/AgCl electrode

A repeatable, electrode-based technology, applied in the field of electrochemistry, can solve the problems of Ag/AgCl layer easy to fall off, low sensitivity, etc., and achieve the effect of low cost, wide application and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

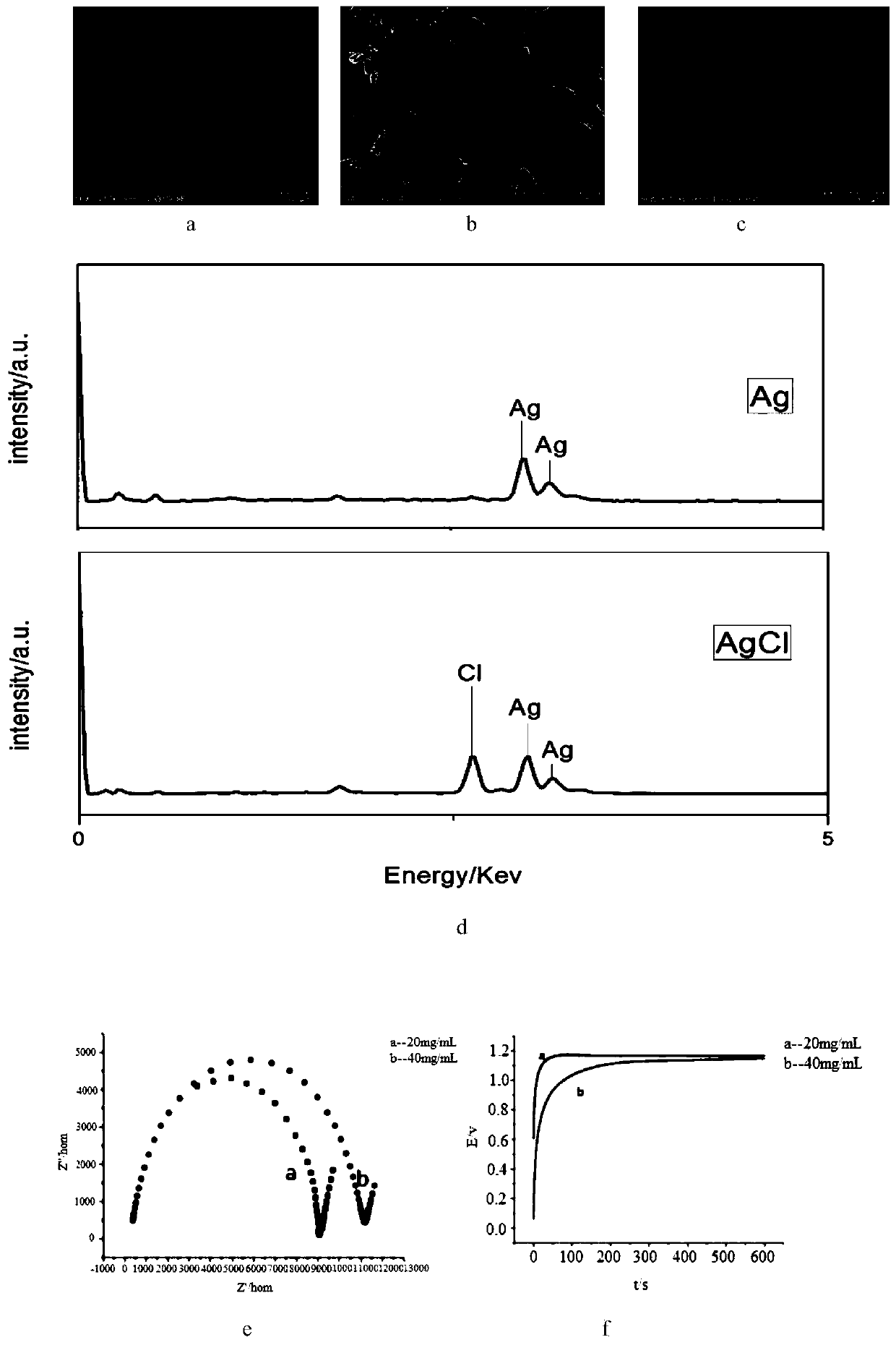

[0026] Embodiment 1 prepares Ag / AgCl reference electrode:

[0027] 1. Preparation of electrode substrate mold:

[0028] (1) Prepare two gluing machines and adjust them to 65°C and 200°C for standby respectively. Take a new silicon wafer and blow it clean with nitrogen, place it on a hot plate, and heat it on the 200°C gluing machine for 5 minutes. The wafer was then cooled at room temperature.

[0029] (2) Place the center of the silicon wafer in alignment with the center of the turntable of the homogenizer, drop the photoresist on the center of the silicon wafer, no air bubbles can be generated during the dropping process, and slowly shake the glue at a speed of 500r / min for 20s , and then place the silicon wafer on a 65° C. baker for 5 minutes, and heat it at 95° C. for 20 minutes. After the heating, the silicon wafer is cooled at room temperature for 10 minutes.

[0030] (3) Place the silicon wafer in the mask and expose it under a UV exposure machine with a wavelength of...

Embodiment 2

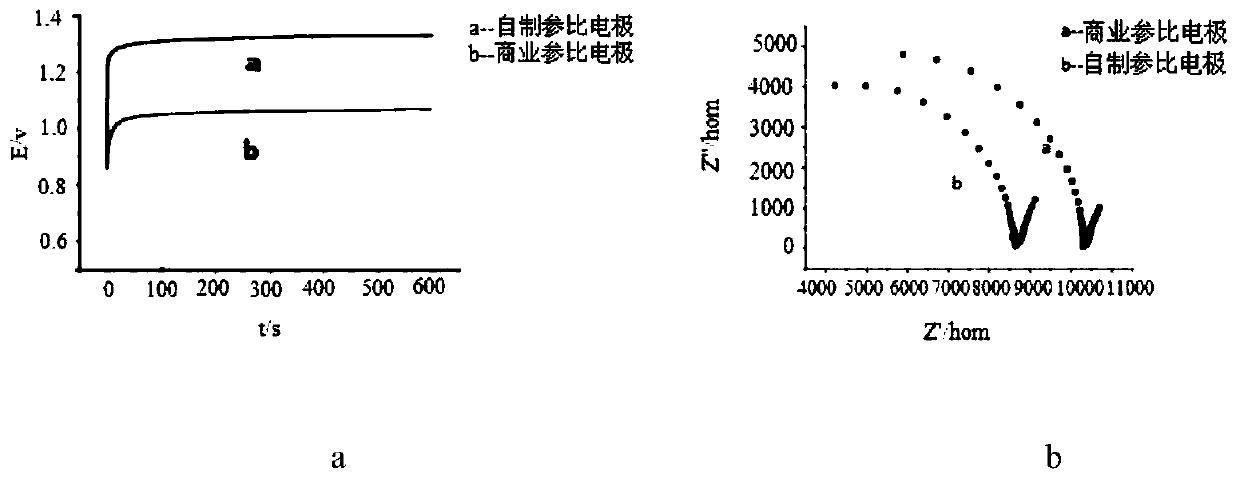

[0038] The Ag / AgCl electrode prepared in Example 1 was used as a reference electrode, the glassy carbon electrode was used as a working electrode, and the platinum wire was used as an auxiliary electrode to form a three-electrode system.

[0039] Pretreatment of glassy carbon electrodes: Grinding and activating glassy carbon electrodes, using Al with different particle sizes 2 0 3 The powder, from large to small, is placed on the buckskin and dripped with less than deionized water to polish the electrode.

[0040] Adopt the three-electrode system of this embodiment to carry out electrode test:

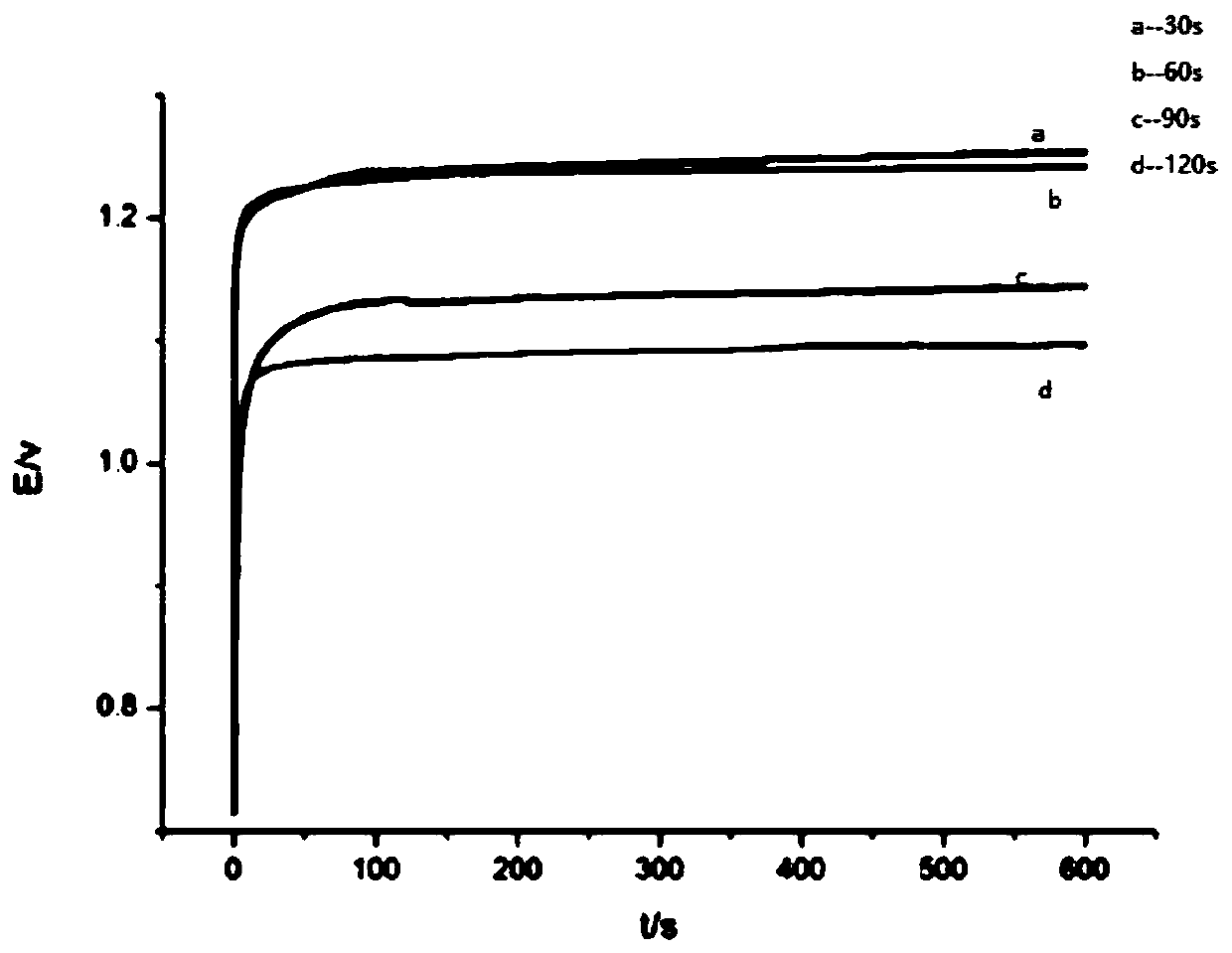

[0041]The three-electrode system is placed in the PBS (10x) buffer solution. Under the three-electrode system, the chronopotentiometry is used to set the cathodic current to 2 μA, the anode current to 2 μA, the cathodic time to 2 s, and the anodic time to 600 s , the initial polarity is anode, the data storage interval is 0.01s, the number of segments is 2, and the electrode polarity...

Embodiment 3

[0044] The three-electrode system consists of a glassy carbon electrode as a working electrode, the nanowire Ag / AgCl prepared in Example 1 as a reference electrode, and a platinum wire as an auxiliary electrode.

[0045] Pretreatment of glassy carbon electrodes: Grinding and activating glassy carbon electrodes, using Al with different particle sizes 2 0 3 The powder, from large to small, is placed on the buckskin and dripped with less than deionized water to polish the electrode.

[0046] Adopt the three-electrode system of this embodiment to carry out electrode test:

[0047] The three-electrode system was placed in potassium ferricyanide (10 -6 mol / L) solution, under the three-electrode system, using cyclic voltammetry, set the scanning potential range from -0.8 to 1.0v, the scanning speed is 0.1v / s, and the number of cycles is 1 cycle. The cyclic voltammetry curve is shown in Figure 15 .

[0048] The process parameters for the preparation of the reference electrode Ag / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com