Treatment method of cyanogen-containing tailing slurry

A treatment method, tailings technology, applied in filtration treatment, water/sewage treatment, metallurgical wastewater treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

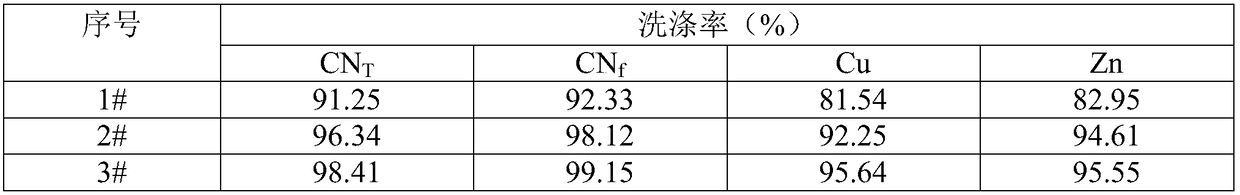

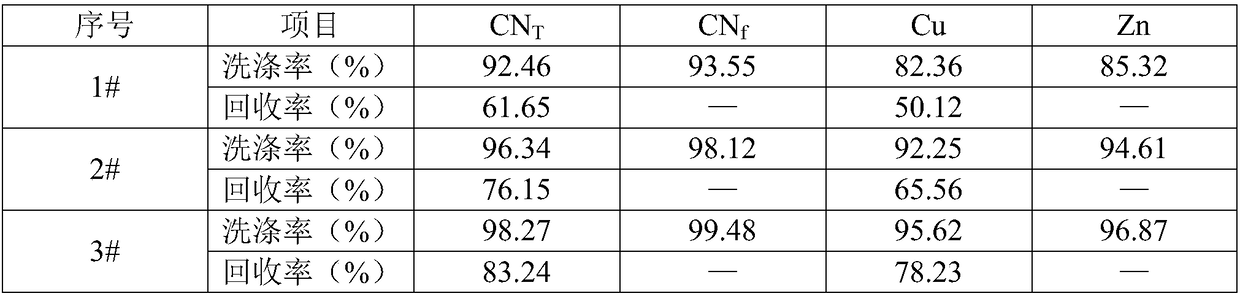

[0029] The main pollutants in the solid phase of cyanide tailings slurry in a gold mine are 78.13mg / kg CNT, 52.45mg / kg CNf, 121.03mg / kg Cu, and 64.56mg / kg Zn.

[0030] Wherein No. 1 cyanide-containing tailings slag is tested according to the following method:

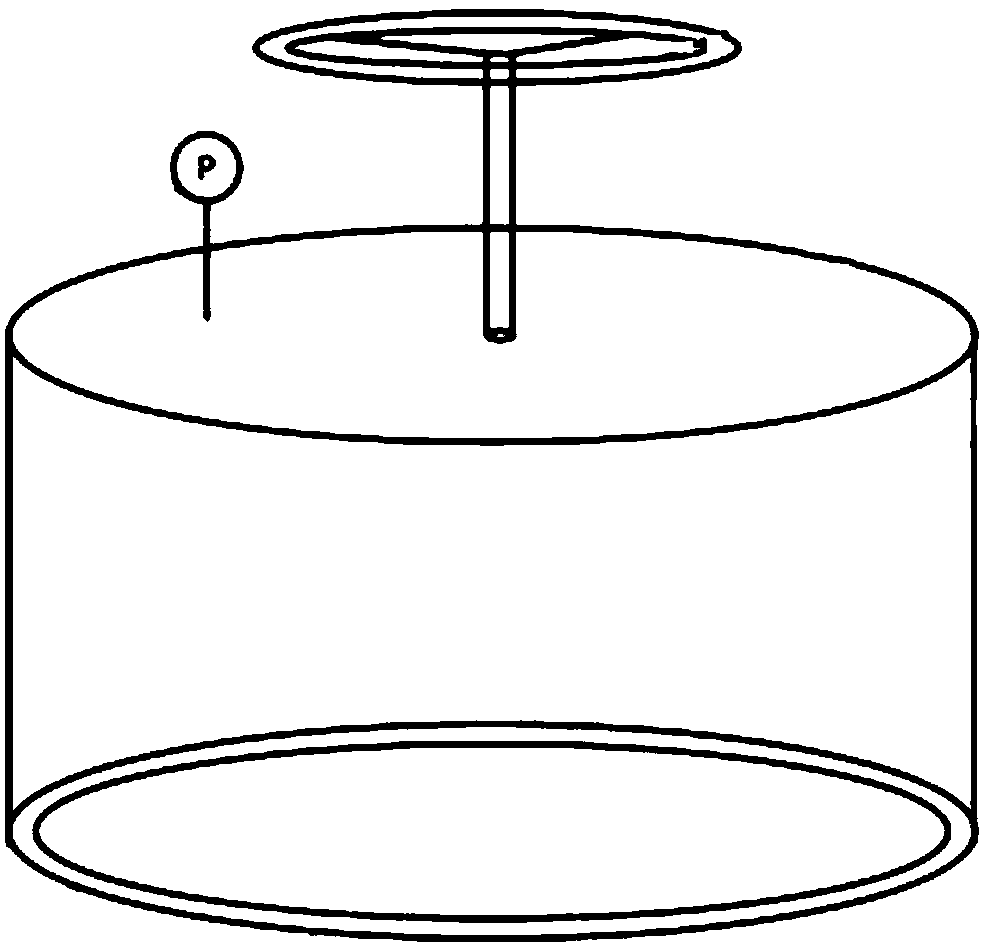

[0031] The cyanide-containing tailings slurry is pumped into the positive pressure filter, and the test device is as follows figure 1 As shown, twist the rotary valve to drive the movable cover plate to close the filter press chamber, open the air source and pass the air through the air inlet for press filtration, the pressure of the filter press chamber is 0.4Mpa, stop the ventilation until the filtrate does not flow out, turn on the water pump from the inlet Pump clean water into the water port for washing. The amount of water pumped in is 0.2 times the weight of the press filter cake. Turn on the air source and pass the air through the air inlet to perform press filtration and blow off. The pressure of the press cham...

Embodiment 2

[0040] The main pollutants in the solid phase of cyanide tailings slurry in a gold mine are 187.17mg / kg CNT, 165.68mg / kg CNf, 197.75mg / kg SCN-, and 253.15mg / kg Cu.

[0041] Wherein No. 1 cyanide-containing tailings slag is tested according to the following method:

[0042]Pump the cyanide-containing tailings slurry into the positive pressure filter, twist the rotary valve to drive the movable cover plate to close the pressure filter chamber, open the air source and pass the air through the air inlet for pressure filtration. The pressure of the filter pressure chamber is 0.4Mpa. Stop the ventilation until it flows out, turn on the water pump to pump the washing liquid from the water inlet (the composition is: sodium dodecylbenzenesulfonate 5mg / L, cyclodextrin 2mg / L, sodium silicate 2mg / L and calcium hydroxide 2mg / L) for water washing, the pumped water volume is 0.2 times the weight of the press filter cake, open the air source and pass the air through the air inlet to perform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com