Method for auxiliary etching conical array silicon surface through pine structure porous copper

A porous copper and silicon surface technology, applied in sustainable manufacturing/processing, climate sustainability, semiconductor devices, etc., can solve the problem of reducing contact area and hydrophobic performance, large top area, which is not conducive to increasing the amount of light and silicon The ability to receive light and other issues, to achieve the effect of excellent hydrophobic properties and the ability to receive light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

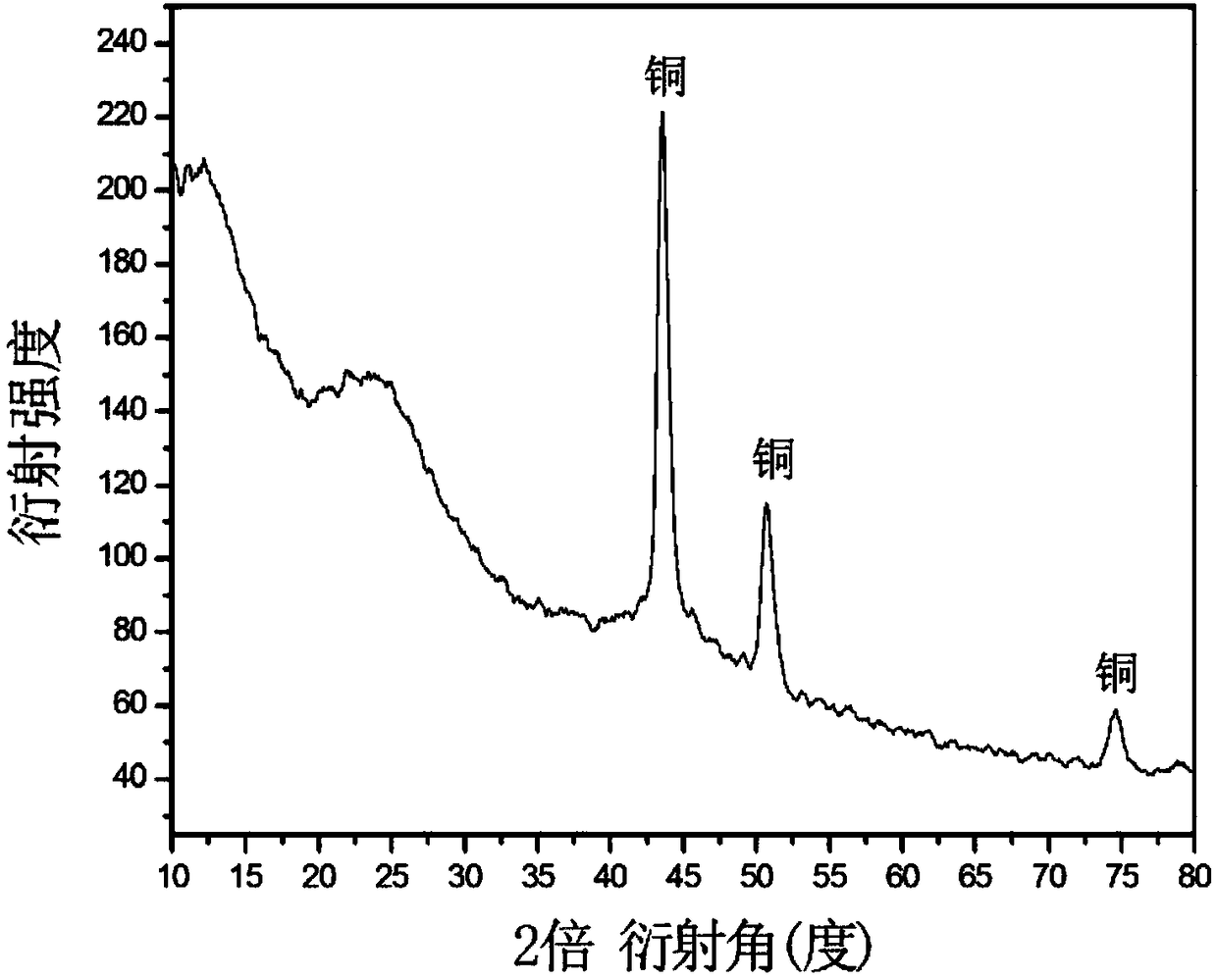

[0036] The white pine wood was placed in an argon-protected sintering furnace and heated to 800 °C at a heating rate of 2 °C / min to obtain a porous carbon with a white pine wood structure; Immersed in the medium for 2 hours, then took out and dried after immersion; the dried porous carbon was sintered to 500 °C in an argon-protected heating furnace to obtain porous copper with a white pine structure; figure 1 Shown is the scanning electron micrograph of the microstructure of the prepared porous copper. It can be seen that the microstructure of the white pine wood is well preserved by the porous copper. figure 2 Shown is the X-ray diffraction pattern of the prepared porous copper, and the material is copper from the diffraction peaks. Prepare a mixed liquid etchant of hydrofluoric acid, hydrogen peroxide, and water. The volume ratio of hydrofluoric acid, hydrogen peroxide, and water is 6:2:2, and immerse the monocrystalline silicon with the etchant. At this time, no corrosion ...

Embodiment 2

[0038] The white pine wood was placed in an argon-protected sintering furnace and heated to 800 °C at a heating rate of 2 °C / min to obtain a porous carbon with a white pine wood structure; After immersion in the carbon for 2 hours, take it out and dry it; the dried porous carbon is sintered to 500 ℃ in an argon-protected heating furnace to obtain porous copper with a white pine structure. Prepare a mixed liquid etchant of hydrofluoric acid, hydrogen peroxide, and water, the volume ratio of hydrofluoric acid, hydrogen peroxide, and water is 6:2:2, and immerse the monocrystalline silicon with the etchant. Press the porous copper on the silicon plane to make it fully contact, so as to play a catalytic role and cause the corrosion reaction to occur. The contact time is 41 minutes, and the silicon-based surface of the cone-shaped array is obtained.

Embodiment 3

[0040] The white pine wood was placed in an argon-protected sintering furnace and heated to 500 °C at a heating rate of 1 °C / min to obtain a porous carbon with a white pine wood structure; Immersed in the carbon for 3 hours, took out and dried after immersion; the dried porous carbon was sintered to 500 °C in an argon-protected heating furnace to obtain porous copper with a white wood structure. Prepare a mixed liquid etchant of hydrofluoric acid, hydrogen peroxide, and water, the volume ratio of hydrofluoric acid, hydrogen peroxide, and water is 6:2:2, and immerse the monocrystalline silicon with the etchant. Press the porous copper on the silicon plane to make it fully contact, so as to play a catalytic role and cause the corrosion reaction to occur. The contact time is 39 minutes, and the silicon-based surface of the cone-shaped array is obtained.

[0041] The porous copper with pine structure used in the present invention is different from other metal catalysts (such as po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com