Method for carrying out laser cladding to form wear-resistant and impact-resistant coating layer on cast iron surface

A technology of laser cladding and impact-resistant layer, which is applied in the direction of coating, metal material coating process, etc., can solve the problems of pores and slag inclusions, and achieve the effects of reducing pores, good metallurgical bonding, and reducing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

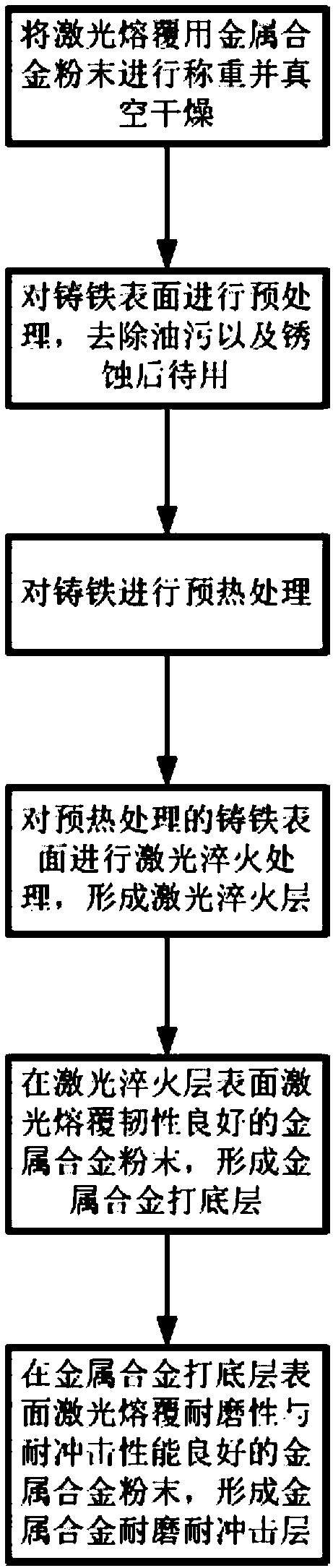

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, vermicular graphite cast iron is used as the matrix, and the base layer material is nickel-based alloy powder. The chemical composition (mass percentage of each element) is: C: 0.02%, Si: 0.1%, Mn: 0.4%, Cr: 15.5%, Co : 2.0%, Mo: 15.5%, W: 3.8%, Nb: 0.31%, Fe: 0.7%, Ni: the balance; the wear-resistant and impact-resistant layer material is iron-based alloy powder, and the chemical composition (mass percentage of each element) is : C: 0.30%, Si: 3.5%, Cr: 10.5%, B: 2.0%, Fe: 10.0%, Ni: balance;

[0051] The specific implementation steps are as follows:

[0052] (1) Dry the nickel-based alloy powder and the iron-based alloy powder in a vacuum oven at 85° C. for two hours after weighing;

[0053] (2) grinding the surface of the vermicular graphite cast iron to be treated with sandpaper for roughening, and then cleaning the oil stain with acetone for use;

[0054] (3) Coat the blackened coating for laser quenching on the surface of vermicular graphite ...

Embodiment 2

[0058] In this embodiment, gray cast iron is used as the matrix, and the base layer material is nickel-based alloy powder. The chemical composition (mass percentage of each element) is: C: 0.025%, Si: 0.12%, Mn: 0.43%, Cr: 16%, Co: 2.4%, Mo: 16%, W: 4.2%, Nb: 0.34%, Fe: 0.75%, Ni: the balance; the wear-resistant and impact-resistant layer material is iron-based alloy powder, and the chemical composition (mass percentage of each element) is: C: 0.32%, Si: 3.9%, Cr: 11, B: 2.3%, Fe: 10.5%, Ni: balance;

[0059] The specific implementation steps are as follows:

[0060] (1) Weigh the nickel-based alloy powder and the cobalt-based alloy powder and dry them in a vacuum oven at 80°C for two hours;

[0061] (2) Grinding the surface of the gray cast iron with sandpaper and carrying out roughening treatment, then cleaning the greasy dirt with acetone for use;

[0062] (3) Coat the blackened coating for laser quenching on the surface of gray cast iron, and then carry out laser quenchi...

Embodiment 3

[0066] In this embodiment, nodular cast iron is used as the matrix, and the base layer material is nickel-based alloy powder. The chemical composition (mass percentage of each element) is: C: 0.03%, Si: 0.14%, Mn: 0.46%, Cr: 16.5%, Co: 2.8%, Mo: 16.5%, W: 4.6%, Nb: 0.37%, Fe: 0.8%, Ni: the balance; the material of the wear-resistant and impact-resistant layer is iron-based alloy powder. The chemical composition (mass percentage of each element) is: C : 0.34%, Si: 4.3%, Cr: 11.5%, B: 2.6%, Fe: 11.0%, Ni: balance;

[0067] The specific implementation steps are as follows:

[0068] (1) After weighing the nickel-based alloy powder and the iron-based alloy powder, dry them in a vacuum oven at 90°C for two hours;

[0069] (2) Polish the surface of the nodular cast iron with sandpaper and carry out roughening treatment, then use acetone to clean the greasy dirt for later use;

[0070] (3) Coat the blackened coating for laser quenching on the surface of ductile iron after mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com