Rolicyprine continuous production system and production method

A production method and technology of a production system, applied in chemical instruments and methods, organic chemistry, carboxylic acid amide preparation, etc., can solve the problems of poor fluidity of reaction liquid, increased viscosity of reaction liquid, inconvenience of continuous production, etc., and achieve product quality and , reduce back-mixing, and stabilize product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

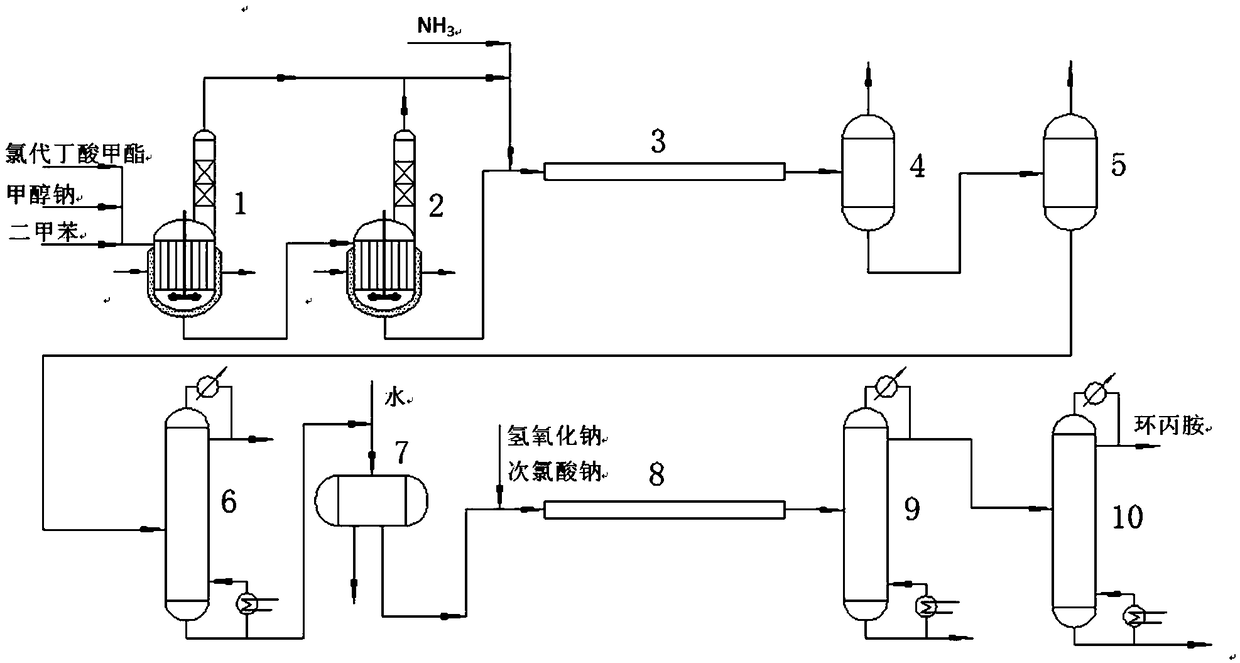

[0053] The production system for the continuous production of cyclopropylamine includes the following production devices connected in order: a first-stage reaction distillation kettle 1 and a second-stage reaction distillation kettle 2, tubular amination reactor 3, ammonia removal tank 4, flash tank 5, Methanol tower 6, phase separator 7, tubular degradation reactor 8, cyclopropylamine continuous crude distillation tower 9, cyclopropylamine continuous fine distillation tower 10, equipment connection pipelines, control instruments and accessories (heating, cooling, safety, etc.) .

[0054] The above devices are connected in sequence, and the direction of the material in each device is (such as figure 1 Shown): The materials (methanol) steamed from the first-stage reaction distillation kettle 1 and the second-stage reaction distillation kettle 2 are mixed with the materials (methyl cyclopropanoate and solvent xylene) from the bottom of the second reaction distillation kettle 2 thro...

Embodiment 2

[0062] The other contents of this embodiment are the same as those of embodiment 1, but the difference is that a 30% sodium methoxide methanol solution is used as the sodium methoxide feed during the cyclization reaction. The purity of cyclopropylamine product is 99.95%, and the total yield is 92%.

Embodiment 3

[0064] The other contents of this embodiment are the same as those of embodiment 1, but the difference is that the reactor for the degradation reaction is a tank reactor, and the reaction temperature is controlled at 0-13°C. The purity of the cyclopropylamine product is 99.95%, and the total yield is 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com