Manganese-based oxide positive electrode material modified by ion conductor layer and its preparation and application

An ion conductor layer, manganese-based oxide technology, applied in the field of energy storage, can solve the problems of unfavorable electrode material rate performance, extremely poor electronic conductivity, improvement and other problems, and achieve fast transmission, high energy density, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) 1g LiNi 0.5 Mn 1.5 O 4 (Solid-phase synthesis) The material was dispersed in 80 mL of ethanol, ultrasonically dispersed for 0.5 h, made into suspension A, and placed in a 60°C water bath;

[0049] (2) Take 100mL 6.2*10 -3 mol / L ethanol dispersed SiO 2 The sol was added to Suspension A, and then 10mL of 0.137mol / L citric acid aqueous solution and 10mL of 0.1mol / L lithium hydroxide aqueous solution were added dropwise at 0.02mL / min and vigorously stirred at a stirring speed of 800rpm. During the dropwise addition, 2.5wt % ammonia solution to adjust the pH of the reaction system to 8.5, and stir for 4h;

[0050] (3) Evaporate to dryness with stirring at 80°C, and calcinate at 500°C for 5 hours to obtain LiNi 0.5 Mn 1.5 O 4 @3wt.%Li 4 SiO 4

[0051] (4) Phase analysis: X-ray diffraction spectrum analysis of the prepared material shows that the obtained material has a spinel structure, belongs to the Fd-3m crystal form, and has a high degree of crystallinity. ...

Embodiment 2

[0056] (1) 1g Ni 0.5 Mn 1.5 O x (Prepared by solid-phase method) The material was dispersed in 100 mL of alcohol-water mixed solution (the volume ratio of ethanol to water was 7:1), and ultrasonically dispersed into suspension A;

[0057] (2) 20mL of 2.5mol / L sodium silicate solution was added dropwise to A at 10mL / min at 85°C, and 2.5wt.% ammonia solution was adjusted to pH~10 of the reaction system, and stirred for 3h;

[0058] (3) The product was centrifuged, washed, dried overnight, mixed with an excess of 10% lithium acetate, and calcined.

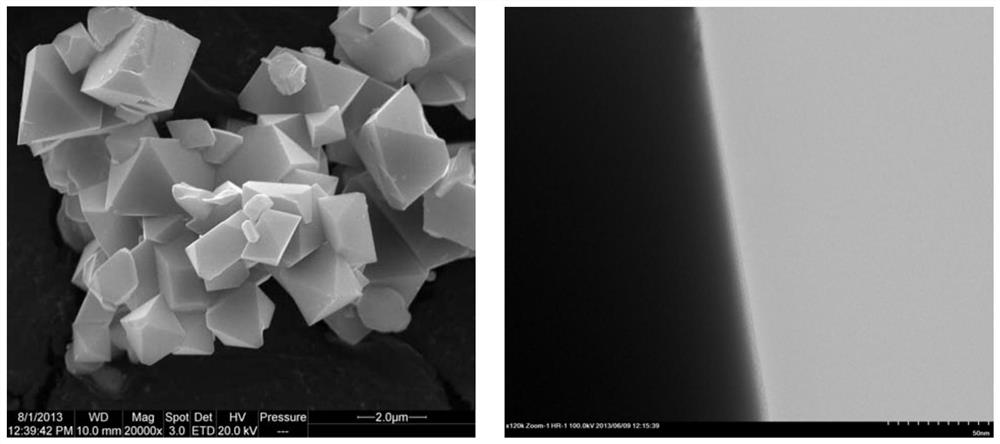

[0059] (4) Phase analysis and morphological characterization: attached Figure 5 The X-ray diffraction spectrum of the obtained material shows that the obtained material has a spinel structure, belongs to the Fd-3m crystal form, and contains a small amount of impurity Li x Ni 1-x O(x ~ 0.2). Investigate the microstructure of the material (attached Image 6 ), the particle size of the material is 2-3 μm and the surface of the ma...

Embodiment 3

[0063] (1) 0.5g LiNi synthesized by liquid phase co-precipitation method 0.4 Cr 0.2 Mn 1.4 O 4 The material was ultrasonically dispersed in 40 mL of deionized water, and 20 mL of an aqueous solution containing 0.05 g of polyetherimide was added and stirred for 2 h, which was called suspension A;

[0064] (2) Add an appropriate amount of lithium acetate solid particles and stir to dissolve, add 0.03 mol / L tetraethyl silicate and aluminum nitrate solution dropwise to A at 20 mL / min at 80°C, and use hydrochloric acid and ammonia solution to control the reaction system pH ~ 4.0 for 2h, stirring speed is 2000rpm;

[0065] (3) After stirring and evaporating the reaction solution to dryness, heat treatment: 500°C for 3h to obtain 0.88LiNi 0.4 Cr 0.2 Mn 1.4 O 4 ·0.07Li 4 SiO 4 ·0.05Li 5 AlO 4 Material.

[0066] (4) Phase analysis and morphological characterization: X-ray diffraction spectrum shows that the obtained material has a spinel structure and belongs to the Fd-3m c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com