Application of jewelry inlay in denture and preparation method thereof

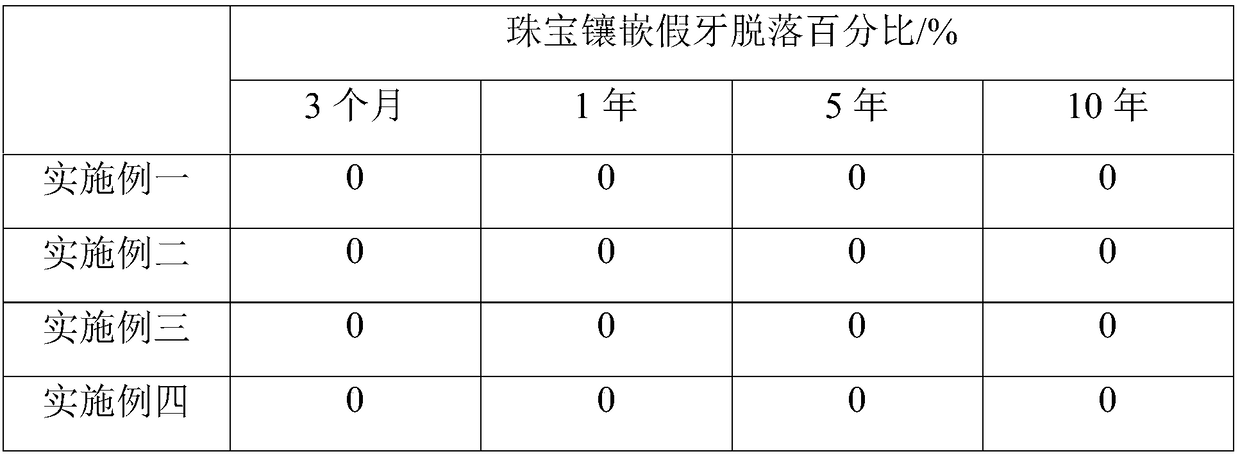

A technology for dentures and jewelry, which is applied in the field of jewelry inlaid in dentures and its preparation, can solve the problems of poor jewelry stability, damage to natural teeth, and lack of aesthetic feeling, achieve good promotion value and application value, and save production costs , the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention provides a kind of artificial tooth preparation method, adopts lost wax casting method, comprises the following steps:

[0026] S101: Wax-type inner crowns or full-form wax crowns are placed on the modified abutment teeth.

[0027] S102: Make the inlays of the hand-carved wax plates. The insets of the wax plates must be smooth and clean, and the structure of each part is reasonable. Confirm that the dimensions of the insets are accurate.

[0028] S103: The labial side (buccal side) of the denture wax-shaped inner crown or the wax-shaped full-form denture crown and the hand-carved wax plate of the jewelry inlay are combined with each other through wax; one kind of inlay or a combination of multiple inlays can be fixed It is located on the labial side (buccal side) of the denture wax-type inner crown or the full-form wax crown of the denture. Confirm that the position of the inlay is correct and position the inlay.

[0029] S104: The wax-type workpi...

Embodiment 2

[0034] The present invention provides a kind of artificial tooth preparation method, adopts CAD software and 3D printing technology, comprises the following steps:

[0035] S101: Use CAD software to scan the model of the trimmed abutment to obtain a three-dimensional digital model of the denture inner crown, and print the denture inner crown through a 3D printer; wherein the medium of the 3D printer is wax.

[0036] S102: Use CAD software to start the computer-carved wax plate inlay to ensure that the size of the inlay is accurate, which greatly improves the speed and accuracy.

[0037] S103: The lip surface (buccal side) of the printed denture wax-type inner crown or denture resin inner crown and the jewelry inlay are combined with each other through wax, and are fixed on the denture with one inlay or a combination of multiple inlays The labial side (buccal side) of the wax-type inner crown or the resin inner crown of the denture, confirm that the position of the inlay is cor...

Embodiment 3

[0043] The invention provides a method for preparing dentures, comprising the steps of:

[0044] S101: Use CAD software to scan the model on the trimmed abutment to obtain a three-dimensional digital model of the denture inner crown, and use a 3D metal printer or a CAD / CAM system metal cutting machine to make a denture metal inner crown; wherein, the medium of the 3D printer is Zirconium powder, the medium of CAD / CAM system cutting machine is block zirconium.

[0045] S102: Use CAD software to start the computer-carved wax plate inlay to ensure that the size of the inlay is accurate, which greatly improves the speed and accuracy.

[0046] S103: The labial surface (buccal side) of the inner crown of the metal denture and the gemstone inlay are welded to make them integrated, and one kind of inlay or a combination of multiple inlays can be fixed on the labial side of the inner crown of the metal denture (buccal side), confirm that the position of the inlay is correct, and posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com