A kind of acid plating solution of rhenium-iridium alloy coating on glass mold surface and preparation method thereof

A glass mold and alloy coating technology, which is applied to the acid plating solution of rhenium-iridium alloy coating on the surface of the glass mold and the field of preparation thereof, can solve the problems of high preparation cost, high equipment cost and the like, achieve uniform distribution of components, low cost, High antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

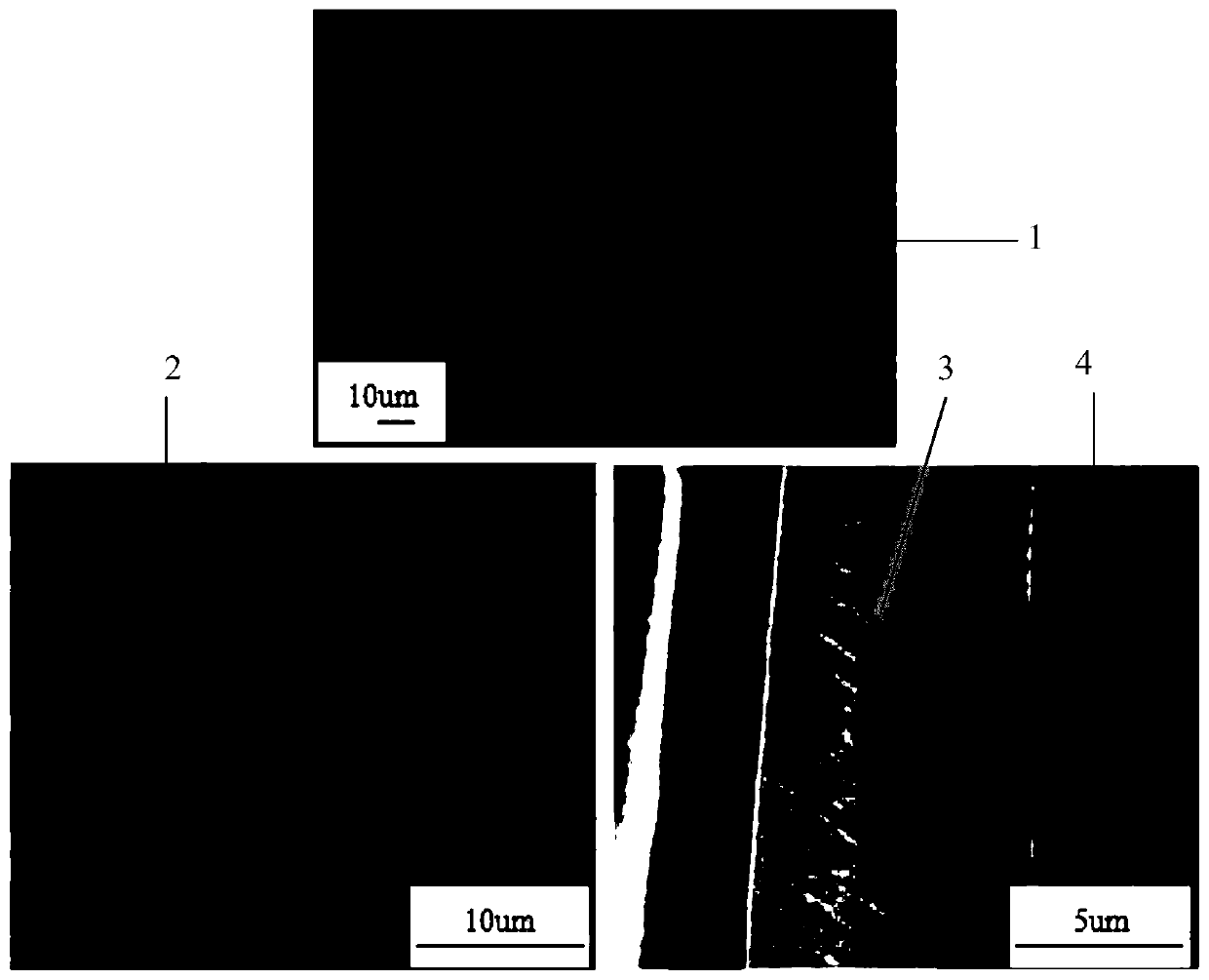

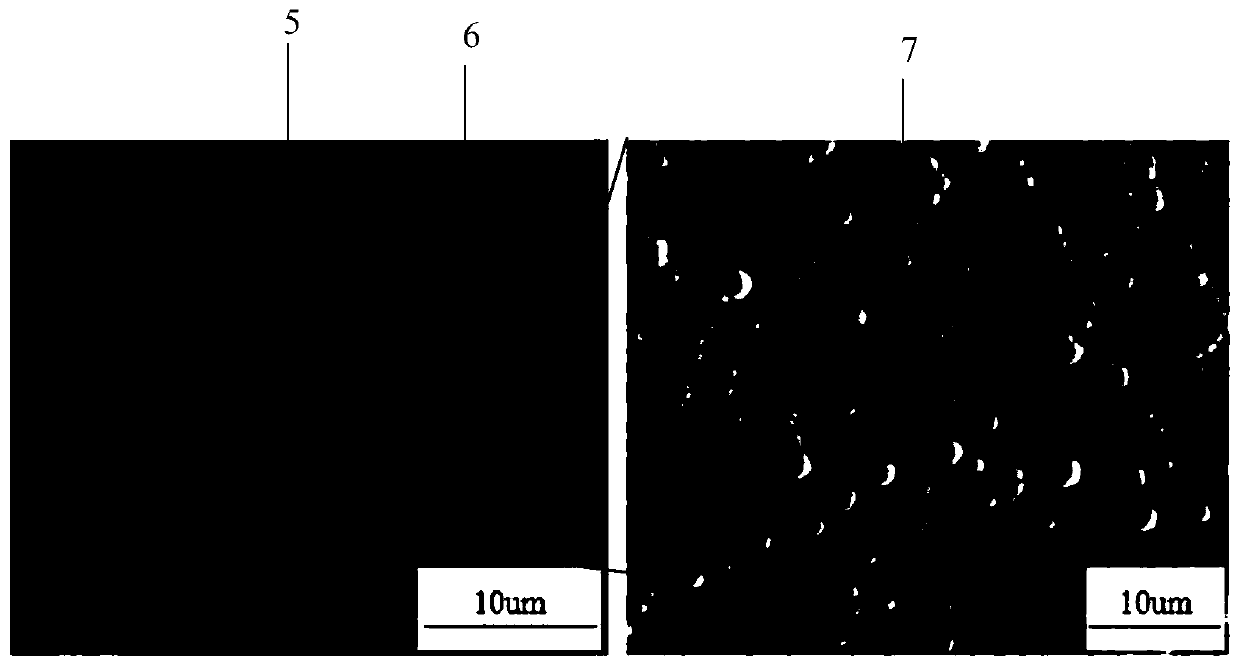

[0016] Prepare 50mL of plating solution, ammonium perrhenate 0.05mol / L, sodium hexabromoiridate 0.045mol / L, chloroiridic acid hydrate 0.005mol / L, without adding any additives and complexing agents, drop 3mol / L Sodium hydroxide solution to adjust the pH of the plating solution to 5.0, add 0.05mol / L potassium chloride, the deposition temperature is 70°C, and the current density is 50mA / cm 2 ; Conduct constant current electrochemical deposition of rhenium-iridium alloy coating on the surface of the copper electrode. The copper electrode is initially ultrasonically cleaned for larger organic matter, and then the surface oxide is removed in a dilute nitric acid solution. Finally, it is cleaned in acetone or ethanol and blown cold. blow dry. Before plating, a layer of nickel thin film is applied on the surface of the copper substrate, and the plating is carried out. During the plating process, the distance between the workpiece electrode and the platinum sheet of the auxiliary elec...

Embodiment 2

[0018] Mix 50mL electrolyte, ammonium perrhenate 0.05mol / L, sodium hexabromoiridate 0.045mol / L, chloroiridic acid hydrate 0.01mol / L, complexing agent citric acid 0.045mol / L, additive is sulfuric acid 0.02mol / L, drop 3mol / L sodium hydroxide solution to adjust the pH of the plating solution to 5.0, set the deposition temperature to 70°C, and the current density to 50mA / cm 2 Conduct constant current electrodeposition of rhenium-iridium alloy on the surface of the copper electrode. The copper electrode is initially ultrasonically cleaned for organic matter, and then the surface oxide is removed in a diluted nitric acid solution, and finally cleaned in acetone or ethanol, and dried with cold air. The distance between the workpiece electrode and the auxiliary electrode platinum sheet is about 0.5cm, the deposition time is 30min, the quality of the coating is good, the current conversion efficiency of the alloy is 55%, the thickness of the coating is 5.1um, and the iridium content in...

Embodiment 3

[0020] Plating solution: ammonium perrhenate 0.043mol / L, sodium hexabromoiridate 0.040mol / L, chloroiridate hydrate 0.010mol / L, complexing agent oxalic acid 0.0375mol / L, additive hydrofluoric acid 0.005mol / L L, configure 50mL plating solution, add 0.02mol / L sulfuric acid solution dropwise to adjust the pH of the plating solution to 2.0, add 0.01mol / L potassium chloride, set the deposition temperature to 70°C, and the current density to 100mA / cm 2 ; Conduct constant current electrochemical deposition of rhenium-iridium alloy coating on the surface of mold steel electrodes, and the copper electrodes are preliminarily cleaned by ultrasonic cleaning of larger organic matter, then the surface oxides are removed and activated in sulfuric acid solution, and finally cleaned in acetone or ethanol , blow dry with cold air. Before plating, a layer of chromium film is applied on the surface of the mold steel electrode, and the plating is carried out. The distance between the workpiece ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com