TPU (thermoplastic polyurethane) elastomer composition with high crystallization capacity and preparation method of TPU elastomer composition

A thermoplastic polyurethane and elastomer technology, which is applied in the field of thermoplastic polyurethane elastomer composition with high crystallization ability and its preparation, can solve the problems of poor crystallization ability and low crystallinity of TPU, achieve Vicat softening point improvement, and preparation process Simple, the effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

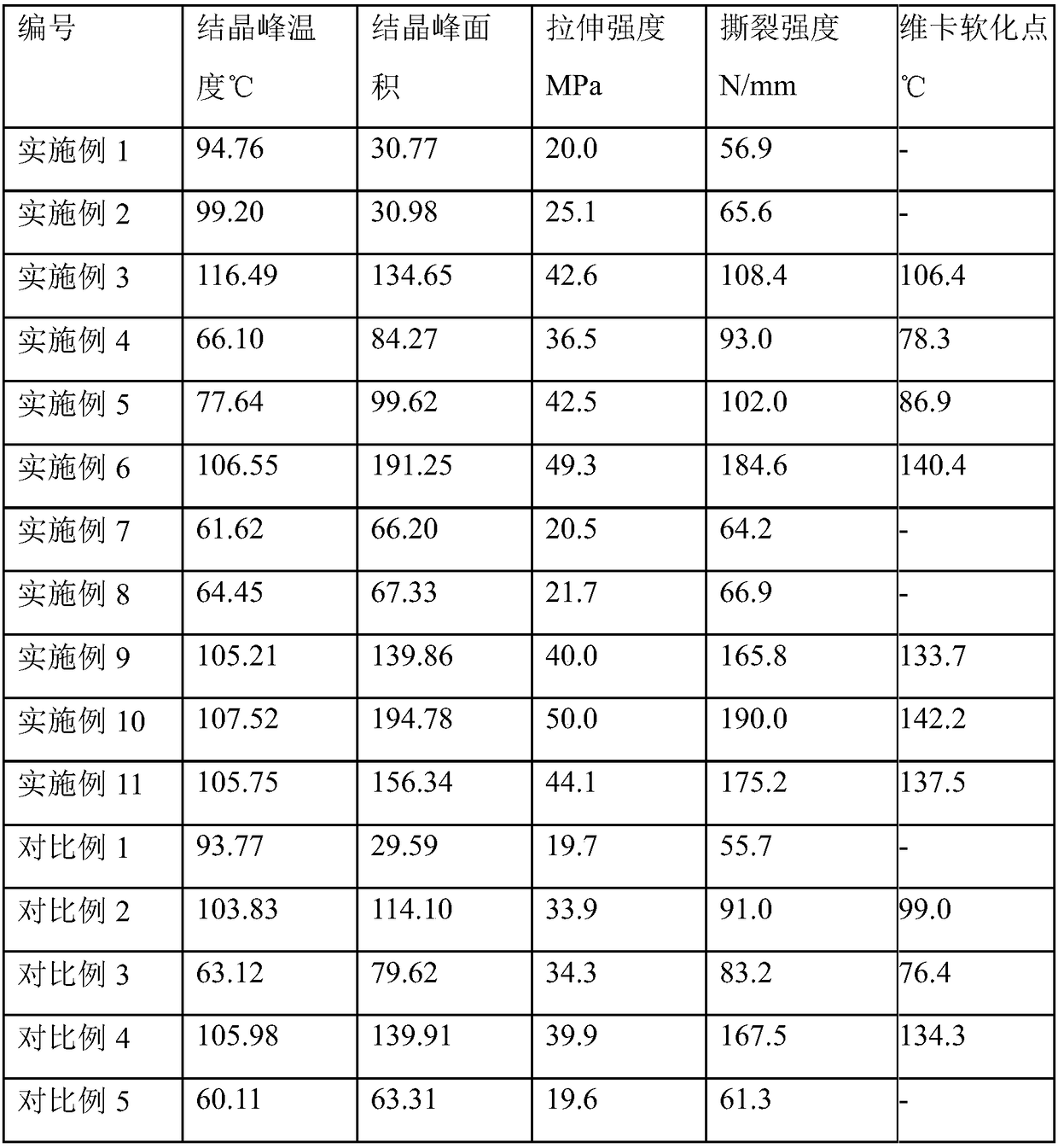

Examples

Embodiment 1

[0036] Select 0.5 parts of unmodified montmorillonite with an average sheet size of 0.02 micron, interlayer spacing of 0.3nm, and ion exchange capacity of 100mmol / 100g,

[0037] Mix with 100 parts of polyether thermoplastic polyurethane elastomer (purchased from Wanhua Chemical Group Co., Ltd., brand WHT-8170) with a hardness of 70A on a high-speed mixer, and extrude the mixture at a temperature of 160-180 ° C The montmorillonite-TPU composite material is obtained by melt blending and extruding on an extruder.

Embodiment 2

[0039]Select montmorillonite with an average sheet size of 0.02 microns, a layer spacing of 0.3 nm, and an ion exchange capacity of 100 mmol / 100 g, and disperse it in water, ultrasonically treat and stir to form a suspension. After standing still, remove the bottom sediment and take the upper layer suspension. Add C8 alkyl primary amine hydrochloride (octylamine hydrochloride) to the montmorillonite suspension, heat to 60°C and stir for 1 hour. After the reaction, the precipitate is washed with deionized water and dried to obtain Organic montmorillonite with modifier content of 30wt%. Take 0.5 part of organic montmorillonite and 100 parts of polyether thermoplastic polyurethane elastomer (same as Example 1) with a hardness of 70A and mix uniformly on a high-speed mixer. The mixture is melted, blended and extruded on an extruder with an extrusion temperature of 160-180° C. to obtain a montmorillonite-TPU nanocomposite material.

Embodiment 3

[0041] Select montmorillonite with an average sheet size of 1 micron, interlayer distance of 2 nm, and ion exchange capacity of 190 mmol / 100 g, disperse it in water, ultrasonically treat and stir to form a suspension. After standing still, remove the bottom sediment and take the upper layer suspension. Add C12 alkyl secondary amine hydrochloride (dilaurylamine hydrochloride) to the montmorillonite suspension, heat to 70°C and stir for half an hour. After the reaction, the precipitate is washed with deionized water and dried. An organic montmorillonite with a modifying agent content of 35 wt % was obtained. Take 1 part of organic montmorillonite and 100 parts of polyether thermoplastic polyurethane elastomer with a hardness of 95A (purchased from Wanhua Chemical Group Co., Ltd., brand WHT-8195) and mix them evenly on a high-speed mixer. The mixture is melted, blended and extruded on an extruder with an extrusion temperature of 180-200° C. to obtain a montmorillonite-TPU nanoco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com