Production technology of high-tenacity copper-clad laminated board with low CTE and high breakage voltage

A technology of copper-clad laminates and high breakdown voltage, which is applied in the field of copper-clad laminates, can solve the problems of poor PCB processing performance, low interlayer bonding strength, and board toughness to be improved, achieving low CTE, Effect of high breakdown voltage and improved processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

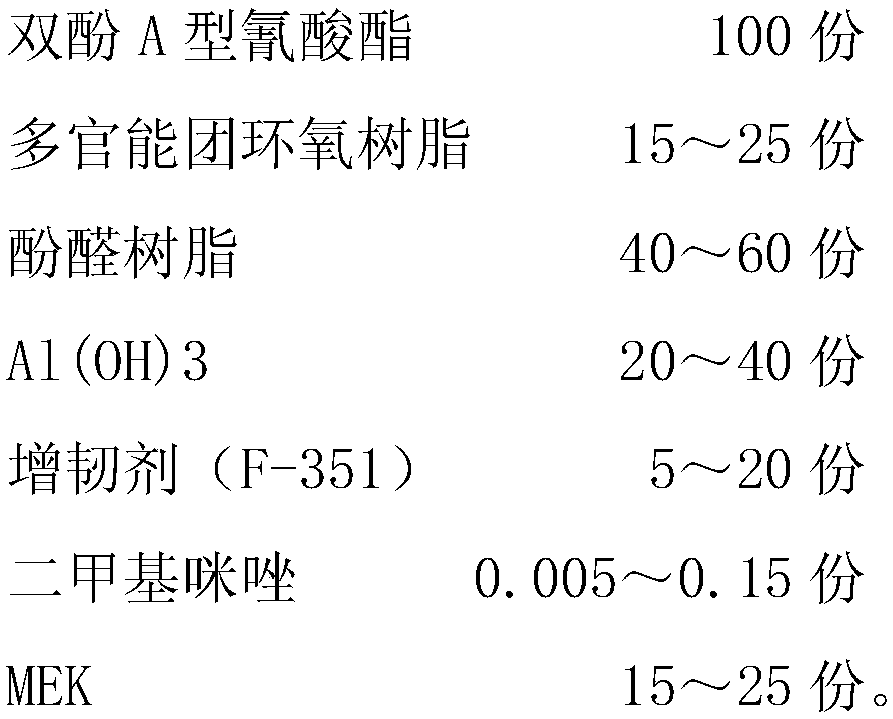

[0020] The technical solution adopted in the present invention is: a production process of a copper-clad laminate with low CTE, high breakdown voltage and high toughness. The production process of the copper-clad laminate comprises the following steps:

[0021] 1). Set the resin glue formula: first transfer the raw materials of the resin glue formula used in the production of copper-clad laminates into the high-speed disperser, and fully mix and stir at a high-speed stirring rate inside the high-speed disperser for 4.5 hours until the mixture is mixed. Uniform, and the test shows that the gelation time of the resin glue is 350s;

[0022] 2). Adjust the production parameters of P sheet: glue the evenly mixed resin glue solution obtained in step 1 on 7628 glass fiber cloth, the resin content after gluing is 43%, and dry it in a vertical gluing machine. Prepreg;

[0023] 3). Adjust the pressing molding process: then stack 8 sheets of prepreg, then laminate them with copper foil,...

Embodiment 2

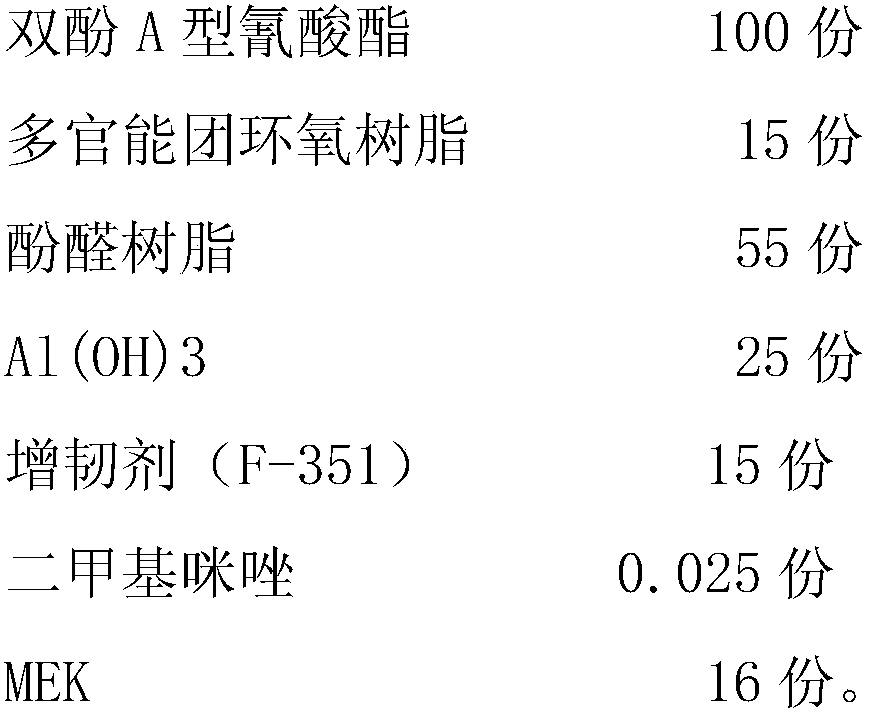

[0031] The technical solution adopted in the present invention is: a production process of a copper-clad laminate with low CTE, high breakdown voltage and high toughness. The production process of the copper-clad laminate comprises the following steps:

[0032] 1). Set the resin glue formula: first transfer the raw materials of the resin glue formula used in the production of copper-clad laminates into the high-speed disperser, and fully mix and stir at a high-speed stirring rate in the high-speed disperser for 6 hours until the mixture is uniform , and test the gelation time of the resin glue;

[0033] 2). Adjust the production parameters of P sheet: glue the evenly mixed resin glue solution obtained in step 1 on 7628 glass fiber cloth, the resin content after gluing is 45%, and dry it in a vertical gluing machine. Prepreg;

[0034] 3). Adjust the pressing molding process: Then stack 9 prepregs, then laminate them with copper foil, and press them in a vacuum press to form th...

Embodiment 3

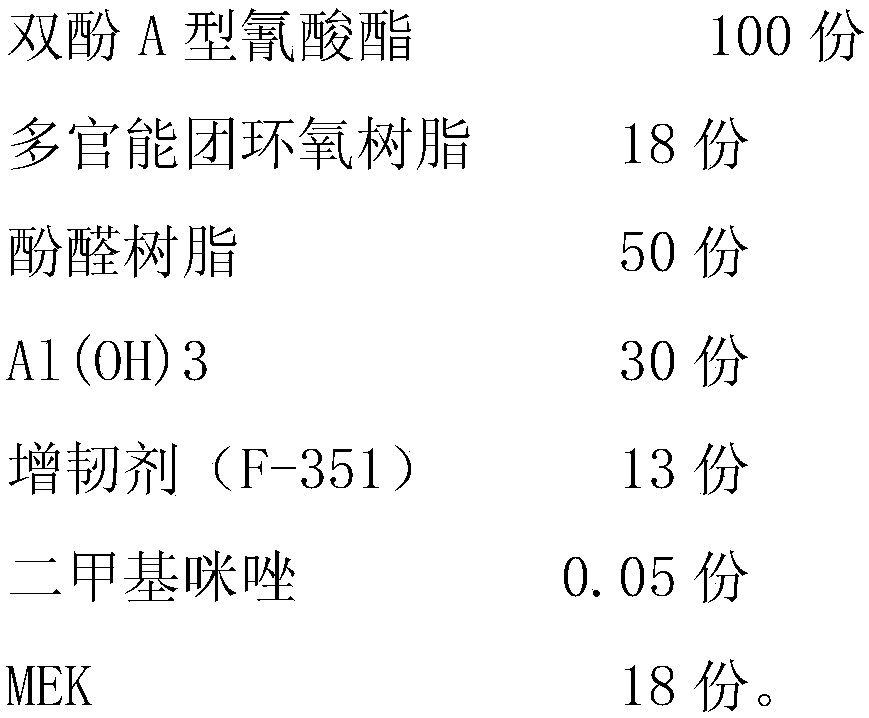

[0042] The technical solution adopted in the present invention is: a production process of a copper-clad laminate with low CTE, high breakdown voltage and high toughness. The production process of the copper-clad laminate comprises the following steps:

[0043] 1). Set the resin glue formula: first transfer the raw materials of the resin glue formula used in the production of copper-clad laminates into the high-speed disperser, and fully mix and stir at a high-speed stirring rate inside the high-speed disperser for 4 hours until the mixture is uniform , and test the gelation time of the resin glue;

[0044] 2). Adjust the production parameters of P sheet: apply the uniformly mixed resin glue solution obtained in step 1 to 7628 glass fiber cloth, the resin content after gluing is 48%, and dry it in a vertical gluing machine. Prepreg;

[0045] 3). Adjust the pressing molding process: then stack 10 sheets of prepreg, then laminate them with copper foil, and press them in a vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com