Polyamide acid slurry, preparation method thereof and polyimide film

A technology of polyamic acid and slurry, which is applied in the fields of polyamic acid slurry and its preparation, polyimide precursor polyamic acid, and polyimide film, can solve the problem that the performance of polyimide film is greatly affected. , The preparation process is difficult to control, the polymerization reaction speed is fast, etc., to solve the difficulty of filtration, reduce the large particles of agglomeration or encapsulation, and improve the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides a method for preparing a polyamic acid slurry applied to a substrate and a film thereof, the method comprising the following steps:

[0037] A first aspect of the present invention provides a method for preparing a polyamic acid slurry, comprising the following steps:

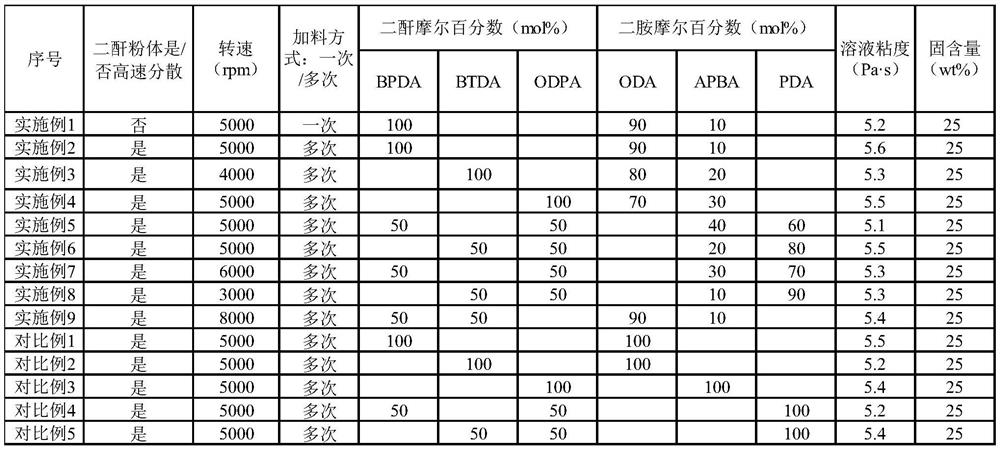

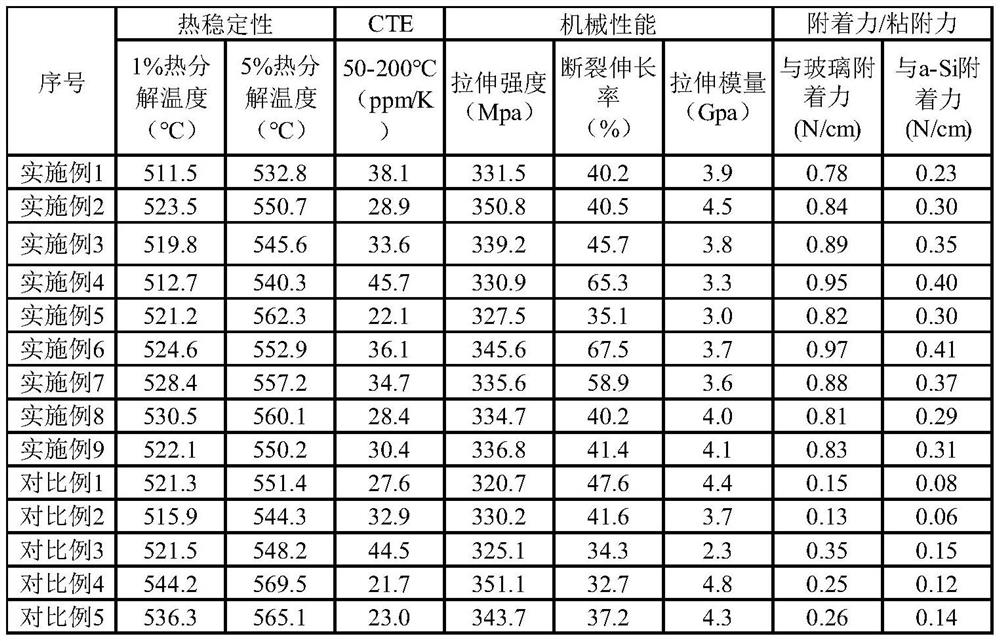

[0038] (1) diamine A1 is dissolved in polar organic solvent E at a certain temperature to obtain diamine A1 solution, and diamine A2 is dissolved in polar organic solvent E at a certain temperature to obtain diamine A2 solution;

[0039] (2) adding dianhydride B1 to organic solvent E, and uniformly distributing B1 in organic solvent E by high-speed dispersing equipment to obtain slurry H1; adding dianhydride B2 to organic solvent E, and uniformly distributing B2 by high-speed dispersing equipment In the organic solvent E, a slurry H2 is obtained; wherein, the state of the dianhydrides B1 and B2 in the organic solvent E is a dissolved or suspended state.

[0040] (3) Add pa...

Embodiment 1

[0097] 1L three-necked flask, 5L constant temperature oil bath, digital display mechanical stirring, high-purity nitrogen pipeline, spherical condenser, liquid-sealed tube and addition funnel, set up the reaction device, continue to feed high-purity nitrogen, first add 6.7278g APBA (0.03mol) and 62.55g NMP, stir in an oil bath at 30°C for about 8min to completely dissolve the diamine APBA, then add 14.1223g BPDA (0.048mol) powder directly and quickly at one time, and add 1.54g methanol, use 86.22g Washed with NMP, the mixed system was reacted at 60°C for 6 hours. Then, the reaction temperature was lowered to 30°C, 54.0621g ODA (0.27mol) and 34.10g NMP were added to the system, the reaction was continued for 6h, and 74.1423g BPDA (0.252mol), 0.2g isoquinoline, 0.5g of triphenyl phosphate and dianhydride BPDA powder were added quickly at one time, and 264.29g of NMP solvent was rinsed.

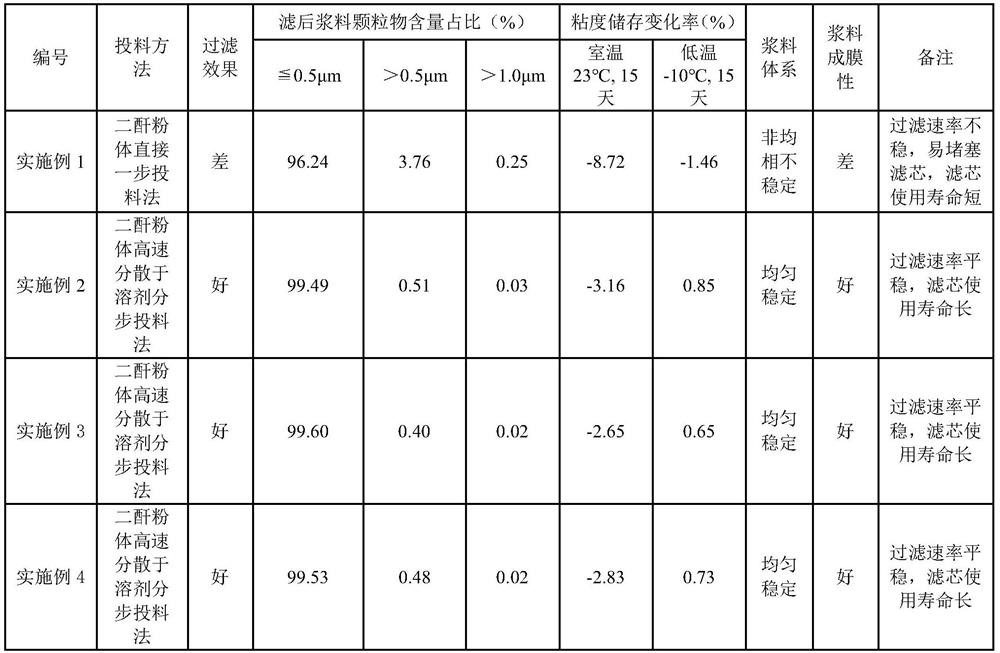

[0098] The obtained polyamic acid slurry viscosity and solid content results are shown in T...

Embodiment 2

[0100] 1L three-necked flask, 5L constant temperature oil bath, digital display mechanical stirring, high-purity nitrogen pipeline, spherical condenser, liquid-sealed tube and addition funnel, set up the reaction device, continue to feed high-purity nitrogen, first add 6.7278g APBA and 62.55 g of NMP, and stirred in an oil bath at 30° C. for 8-10 min to completely dissolve the diamine APBA. 88.2646g BPDA powder of dianhydride was dispersed in 291.27g NMP at high speed, the temperature of the dispersing kettle was set at 30°C, the stirring rate was 5000rpm, and the dispersion time was 2h, to prepare a uniform dianhydride suspension H1 for later use. Then, the homogeneous suspension of 16% H1 (0.048mol BPDA) in mass ratio was slowly and uniformly added to the above diamine solution, and 1.54 g of methanol was added, and the mixed system was reacted at 60° C. for 6 hours. Next, the reaction temperature was lowered to 30°C, 54.0621g ODA and 34.10g NMP were added to the system, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com