Needle coke preparation method and device

A technology of needle coke and coking wax oil, applied in coking ovens, coking carbonaceous materials, petroleum industry, etc., can solve problems affecting the quality of needle coke, incomplete development, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

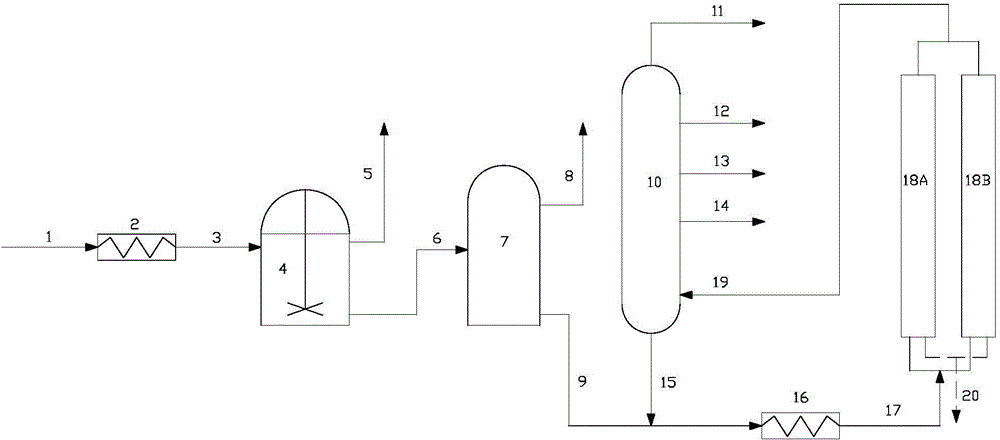

Method used

Image

Examples

Embodiment 1

[0031] Catalytic cracking clarified oil treated in a certain refinery is used as raw material, and its properties are shown in Table 1. The coker wax oil added is the middle distillate oil separated by the fractionation system, and the addition amount is 10%, which is heated to 385°C in a pretreatment heating furnace After that, it enters into a stirred reactor and stays for 4 hours under the conditions of temperature 375°C, pressure 1MPa, and stirring rate 250r / min. Then enter the buffer tank 7 through the pipeline 6, the temperature of the buffer tank is 250°C, and the pressure is 0.3MPa. The raw oil flowing out of the buffer tank is mixed with the heavy distillate oil separated from the coking fractionation tower. After being heated by the coking heating furnace, it enters the delayed coking tower for coking reaction. The coking heating furnace is controlled by variable temperature. The initial temperature is 435 ° C for 2 hours, and then the temperature is raised to 480 ° ...

Embodiment 2

[0035] The wax oil fraction obtained after thermal cracking of residue oil is used as raw material, and its properties are shown in Table 1. The added coker wax oil is the heavy distillate oil separated by the fractionation system. The addition amount is 5%, and it is heated by a pretreatment heating furnace After reaching 375°C, it enters into a stirred reactor, and stays for 6 hours at a temperature of 365°C, a pressure of 0.8MPa, and a stirring rate of 250r / min. The treated raw oil enters the buffer tank, the temperature of the buffer tank is 280°C, and the pressure is 0.2MPa. The raw oil flowing out of the buffer tank is mixed with the heavy distillate oil separated from the coking fractionation tower, heated by the coking heating furnace, and then enters the delayed coking tower for coking reaction. Raise the temperature to 480°C at a uniform speed within 10 hours, during which the coking cycle ratio is controlled to 0.8 and the pressure is 1.5MPa; feed at a constant temp...

Embodiment 3

[0039] The raw materials are the same as in Example 1, the added coker wax oil is the middle distillate oil separated by the fractionation system, and the addition amount is 8%. After being heated to 375°C in the pretreatment heating furnace, it enters the reactor with stirring. Under the conditions of 2MPa and stirring rate of 350r / min, stay for 6h. The treated raw oil enters the buffer tank 7 through the pipeline 6, the temperature of the buffer tank is 300° C., and the pressure is 0.2 MPa. The raw oil flowing out of the buffer tank is mixed with the heavy distillate oil separated from the coking fractionation tower, heated by the coking heating furnace, and then enters the delayed coking tower for coking reaction. Raise the temperature to 470°C at a constant speed within 15 hours, during which the coking cycle ratio is controlled to 0.8 and the pressure is 2MPa; feed at a constant temperature of 470°C for 2 hours, and at the same time increase the coking cycle ratio to 1.5;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com