Flame-resistant waterproof lignin-modified asphalt roll and production method thereof

A technology for modifying asphalt and waterproofing membranes, applied in chemical instruments and methods, layered products, building insulation materials, etc., can solve problems such as safety accidents, and achieve enhanced interfacial bonding force, improved interfacial bonding strength, and excellent flame retardancy. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

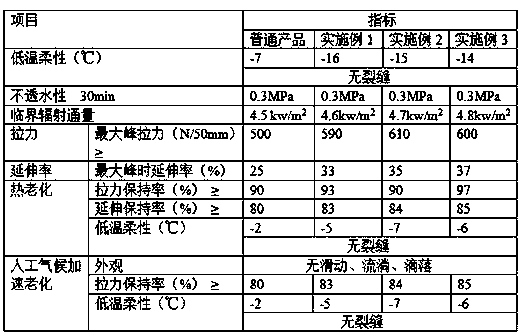

Embodiment 1

[0033] A flame-retardant lignin-modified asphalt waterproof membrane, the waterproof membrane is a five-layer structure, from top to bottom: the upper surface isolation layer, the upper flame-retardant modified asphalt layer, the base layer, the lower resistance flame retardant modified asphalt layer and lower surface isolation layer; the upper flame retardant modified asphalt layer and the lower flame retardant modified asphalt layer are made of flame retardant modified asphalt, and the flame retardant modified asphalt The asphalt is made of the following raw materials in parts by weight: 40 parts of phenolized lignin; 20 parts of SBS modifier; 50 parts of 90# petroleum asphalt; 5 parts of γ-aminopropyltriethoxysilane; 5 parts of calcium carbonate; 5 parts of polyoxyethylene polyoxypropanolamine ether; 6 parts of citric acid; 6 parts of fumed silica; 1.6 parts of dimethyl methylphosphonate; 3.2 parts of microencapsulated red phosphorus; acetylcitric acid 3 parts of trihexyl e...

Embodiment 2

[0043]A flame-retardant lignin-modified asphalt waterproof membrane, the waterproof membrane is a five-layer structure, from top to bottom: the upper surface isolation layer, the upper flame-retardant modified asphalt layer, the base layer, the lower resistance flame retardant modified asphalt layer and lower surface isolation layer; the upper flame retardant modified asphalt layer and the lower flame retardant modified asphalt layer are made of flame retardant modified asphalt, and the flame retardant modified asphalt The asphalt is made from the following raw materials in parts by weight: 45 parts of phenolized lignin; 23 parts of SBS modifier; 55 parts of 90# petroleum asphalt; 2 parts of diethylenetriaminopropyltrimethoxysilane; γ- 3 parts of ethylenediaminotriethoxysilane; 3 parts of tri-tert-butoxyvinylsilane; 7 parts of modified nano-calcium carbonate; 7 parts of polyoxyethylene polyoxypropanolamine ether; 8 parts of citric acid; 8 parts of silicon oxide; 1.7 parts of d...

Embodiment 3

[0053] A flame-retardant lignin-modified asphalt waterproof membrane, the waterproof membrane is a five-layer structure, from top to bottom: the upper surface isolation layer, the upper flame-retardant modified asphalt layer, the base layer, the lower resistance flame retardant modified asphalt layer and lower surface isolation layer; the upper flame retardant modified asphalt layer and the lower flame retardant modified asphalt layer are made of flame retardant modified asphalt, and the flame retardant modified asphalt The asphalt is made from the following raw materials in parts by weight: 50 parts of phenolized lignin; 25 parts of SBS modifier; 60 parts of 90# petroleum asphalt; 3 parts of γ-methacryloxypropyltrimethoxysilane; 3 parts of γ-ureidopropyl triethoxysilane; 4 parts of (3-aminopropyl) triethoxysilane; 8 parts of modified nano-calcium carbonate; 8 parts of polyoxyethylene polyoxypropanolamine ether; lemon 9 parts of fumed silica; 2.4 parts of dimethyl methylphosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com