Light source component

A technology of components and light sources, applied in the field of semiconductor optoelectronics, can solve the problems of affecting the working junction temperature of the chip, reducing the thermal conductivity of the chip, affecting the heat dissipation of the chip, etc., to improve the welding qualification rate, improve the stability, and ensure the effect of welding yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

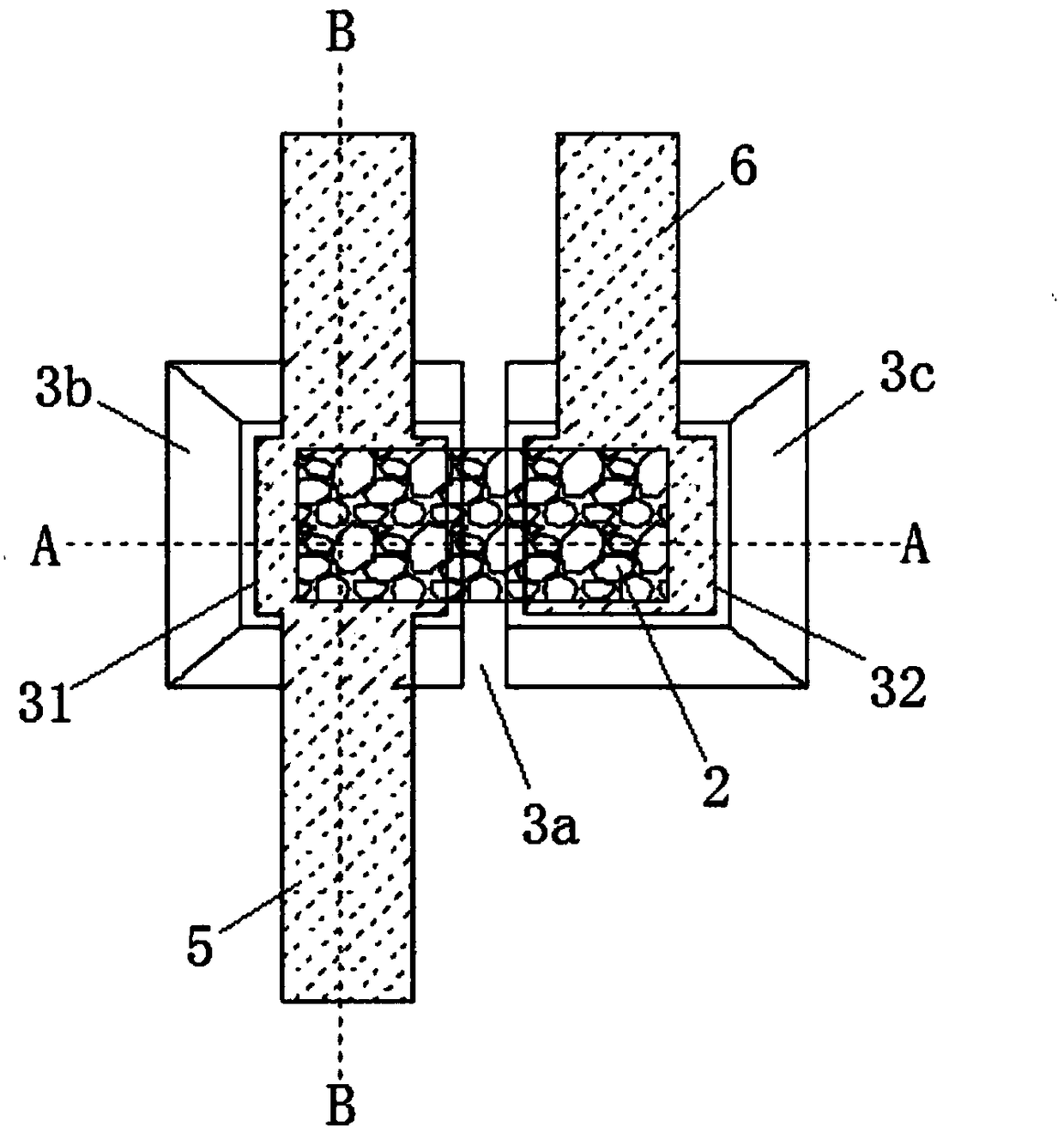

[0025] The reference signs are: substrate body 1, LED chip 2, N electrode 21, P electrode 22, insulating wall 23, mounting boss 3, isolation groove 3a, negative conduction slope 3b, positive conduction slope 3c, negative electrode Area 31 , positive electrode area 32 , thermally conductive insulating layer 4 , negative electrode lead 5 , positive electrode lead 6 , solder 7 .

[0026] The invention discloses a light source element which has strong heat dissipation capability and can prevent electric leakage failure caused by mutual overflow of solder, and improve the qualified rate of product production. The light source element includes a substrate body 1 and a plurality of LEDs welded on the substrate body 1 by solder The chip 2 and the substrate body 1 have good thermal conductivity to facilitate heat dissipation. The best material of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com