Silica-nitrilotriacetic acid-platinum catalyst and preparation method and use thereof

A nitrilotriacetic acid, silica technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. Problems such as low availability and affecting catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

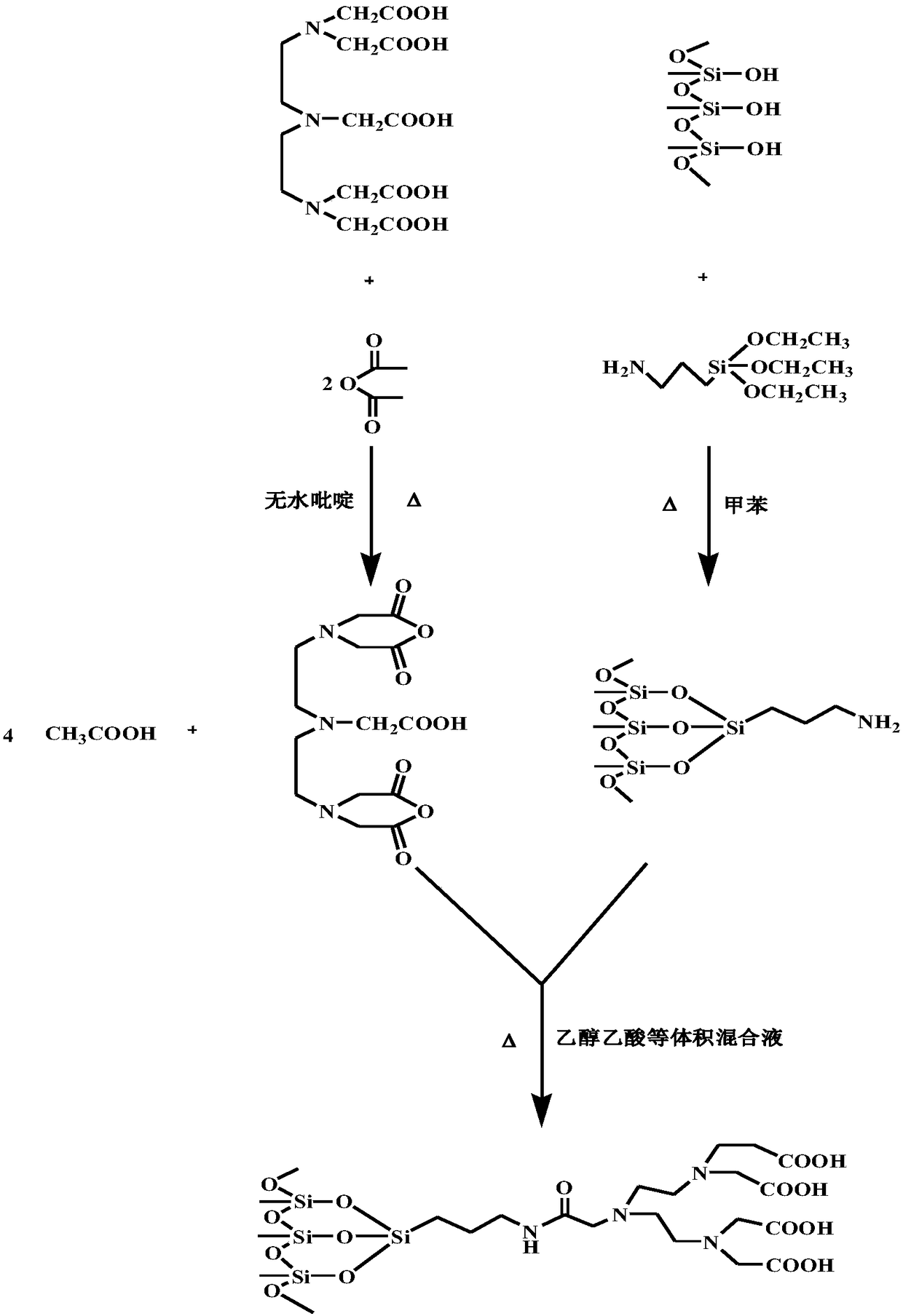

[0070] The preparation of the silicon dioxide supported platinum catalyst modified by polyamino polycarboxylate material, concrete steps are as follows:

[0071] Step 1. Amino functional modification of the basic solid-carrying material silica: SiO 2 Place in 6M hydrochloric acid and reflux at 60°C for 6 hours. After the reaction, wash with distilled water until neutral, and dry in a blast drying oven to obtain acidified silica gel. Take the acidified silica gel and place it in a vacuum drying oven at 130°C for 3h activation to obtain activated SiO 2 . Weigh 5g activated SiO 2Place in a three-necked flask filled with 50mL of toluene, add 7mL of APTES, namely 3-aminopropyltriethoxysilane, and stir mechanically at 110°C for 24h; product, and the product was placed in a 70 ° C forced air drying oven for 24 hours to obtain amino-bonded silica gel (APSG).

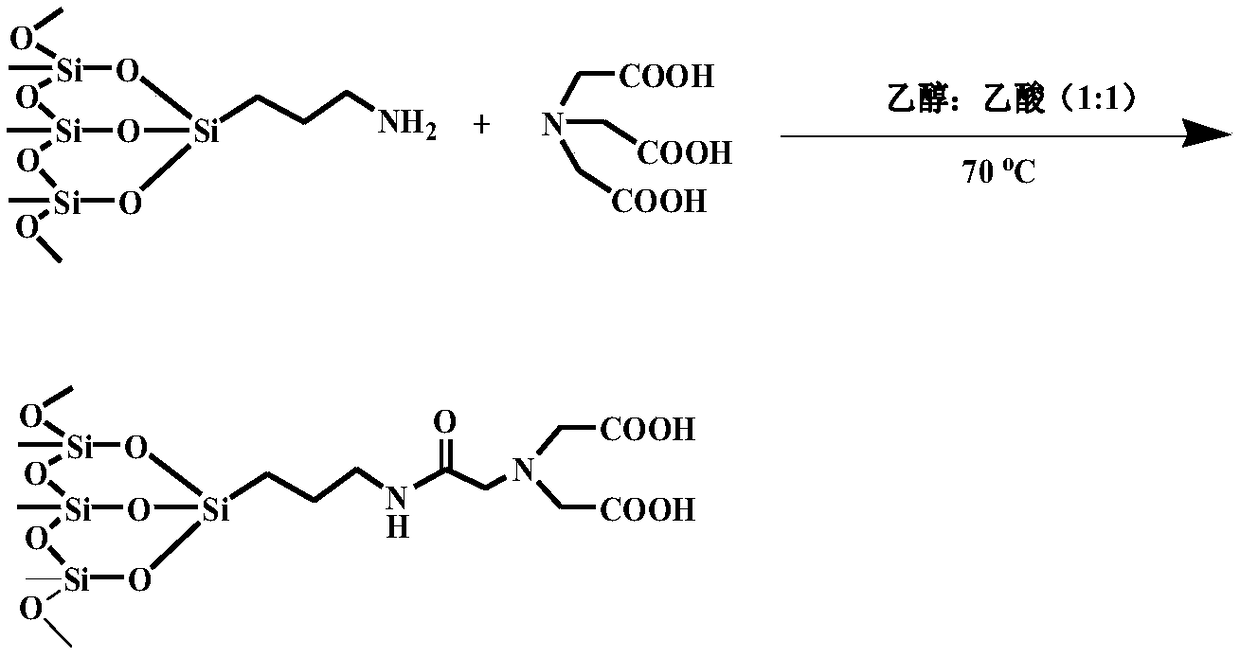

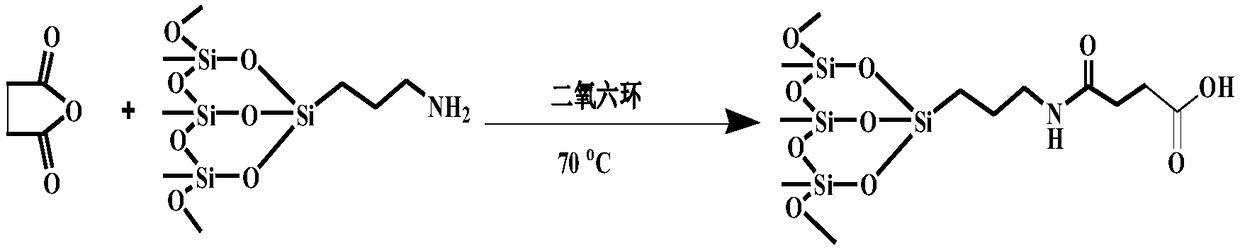

[0072] Step 2, discuss the preparation of three intermediates:

[0073] The first: silicon dioxide - diethyltriaminepenta...

Embodiment 2

[0081] To the IR of related substance in embodiment 1, 1 HNMR, 13 CNMR, TEM, EDS and XPS characterization: The structure of DTPAD was preliminarily confirmed by IR method. Such as Figure 4 As shown, 1816, 1770, 1641cm -1 The appearance of characteristic peaks such as the preliminary verification of the structure of the product; DTPAD was dissolved in DMSO for 1 HNMR and 13 Characterization of CNMR, DTPAD 1 HNMR such as Figure 5 As shown, 2.96(d,4H), 3.15(s,4H), 3.47(s,8H), 3.75(s,1H) and DTPAD 13 CNMR such as Figure 6 As shown, 49.47(2C), 51.48(2C), 54.81(4C), 168.90(1C), 172.57(4C), the results further verified the structure of DTPAD. Figure 7 The results compared to SiO 2 , SiO 2 -NH 2 , SiO 2 -DTPA, SiO2 2 - the difference in the IR absorption peaks of DTPA-Pt, Figure 8 compared to SiO 2 , SiO 2 -NH 2 , SiO 2 -NTA, SiO 2 -IR absorption peaks of NTA-Pt, SiO 2 , SiO 2 -NH 2 , SiO 2 -SA, SiO 2 - The IR absorption peaks of SA-Pt are different as F...

Embodiment 3

[0083] Measure three parts of 0.01mol 1-hexene respectively in centrifuge tubes, and add them respectively according to the preparation method of the present invention. During the immobilization process of platinum, mechanically stir under the protection of nitrogen, the solvent is ethanol, and the immobilization temperature is below 78°C. Prepared SiO 2 -DTPA-Pt (with a Pt content of 2.8×10 -3 mmol), SiO 2 -NTA-Pt (with a Pt content of 2.3×10 -3 mmol), SiO 2 -SA-Pt (with a Pt content of 2.9×10 -3 mmol), after activation at 60°C for 30 minutes, add 0.018 mol of methyl dichlorosilane, seal and add a condensing device, and continue to react for 4 hours. After the reaction, cool to room temperature, take the supernatant, and perform membrane filtration , GC test, GC results such as Figure 20 As shown, compared with the GC retention time of n-hexylmethyldichlorosilane standard substance, it can be preliminarily determined that the product is the target product n-hexylmethyld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com