Fe base-molecular sieve catalyst used for Fischer Tropsch-oligomerization coupling reaction, and preparation method and application thereof

A technology of coupling reaction and catalyst, applied in molecular sieve catalyst, catalyst activation/preparation, preparation of liquid hydrocarbon mixture, etc. The effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Following embodiment is used for the preparation method of the Fe base-molecular sieve catalyst of Fischer-Tropsch-oligomerization coupling reaction, and its specific steps are as follows:

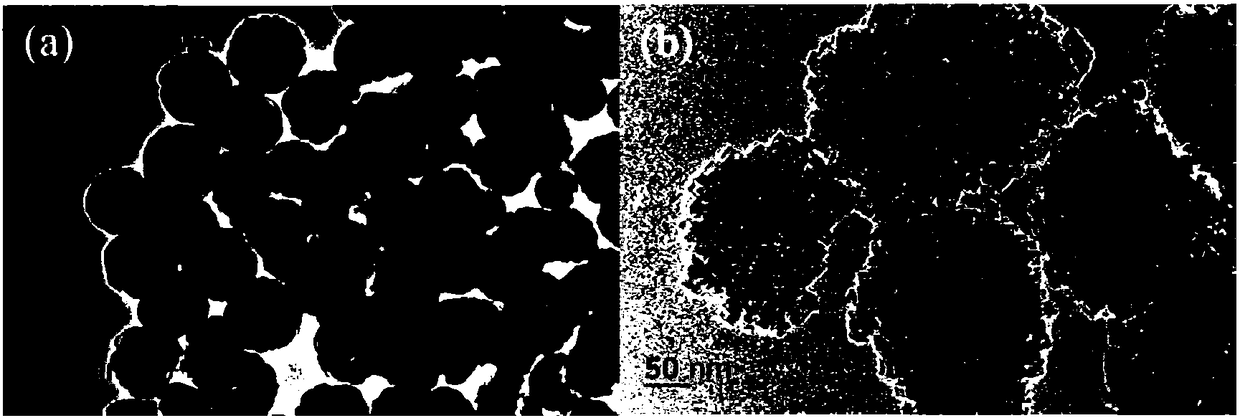

[0030] (1) Nano Fe 3 o 4 Preparation of the microsphere catalyst: dissolve the iron precursor in ethylene glycol at room temperature and stir evenly, then add sodium acetate to the solution and continue to stir evenly, the mass ratio of the iron precursor to sodium acetate is 3-4:8, and the obtained The solution was hydrothermally reacted at 200°C for 12 hours in the reaction vessel, then cooled naturally to room temperature, the black precipitate in the solution after the reaction was separated, and the black precipitate was washed several times with deionized water and ethanol, and then dried to obtain nano-Fe 3 o 4 microsphere catalyst;

[0031] (2) Preparation of nano-HZSM-5 catalyst: Mix deionized water, aluminum isopropoxide, TEOS and TPAOH at room temperature and stir well...

Embodiment 1

[0034] Catalyst preparation:

[0035] Nano Fe 3 o 4 Microsphere catalyst preparation: weigh 1.35g FeCl 3 ·6H 2 Dissolve O in 40mL of ethylene glycol, stir until a uniform solution is formed, then slowly add 3.6g of sodium acetate, continue stirring for 30min until a uniform solution is formed, then transfer the solution to a 70mL polytetrafluoroethylene hydrothermal reaction kettle, seal it completely, The hydrothermal reaction was carried out at 200° C. for 12 h, and cooled to room temperature after the hydrothermal reaction was completed. The black precipitate in the solution after the reaction was separated, and the obtained black precipitate was washed 3 times with deionized water and ethanol, and then the black precipitate was transferred to a vacuum drying oven and dried at 60°C for 12 hours to obtain nano-Fe 3 o 4 microsphere catalyst.

[0036] Preparation of nanometer HZSM-5: Take 30mL deionized water, 0.34g aluminum isopropoxide, 13.89g TEOS and 13.56g TPAOH (th...

Embodiment 2

[0040] Nano Fe 3 o 4 The preparation method of microsphere catalyst and HZSM-5 catalyst is the same as embodiment 1, and difference is:

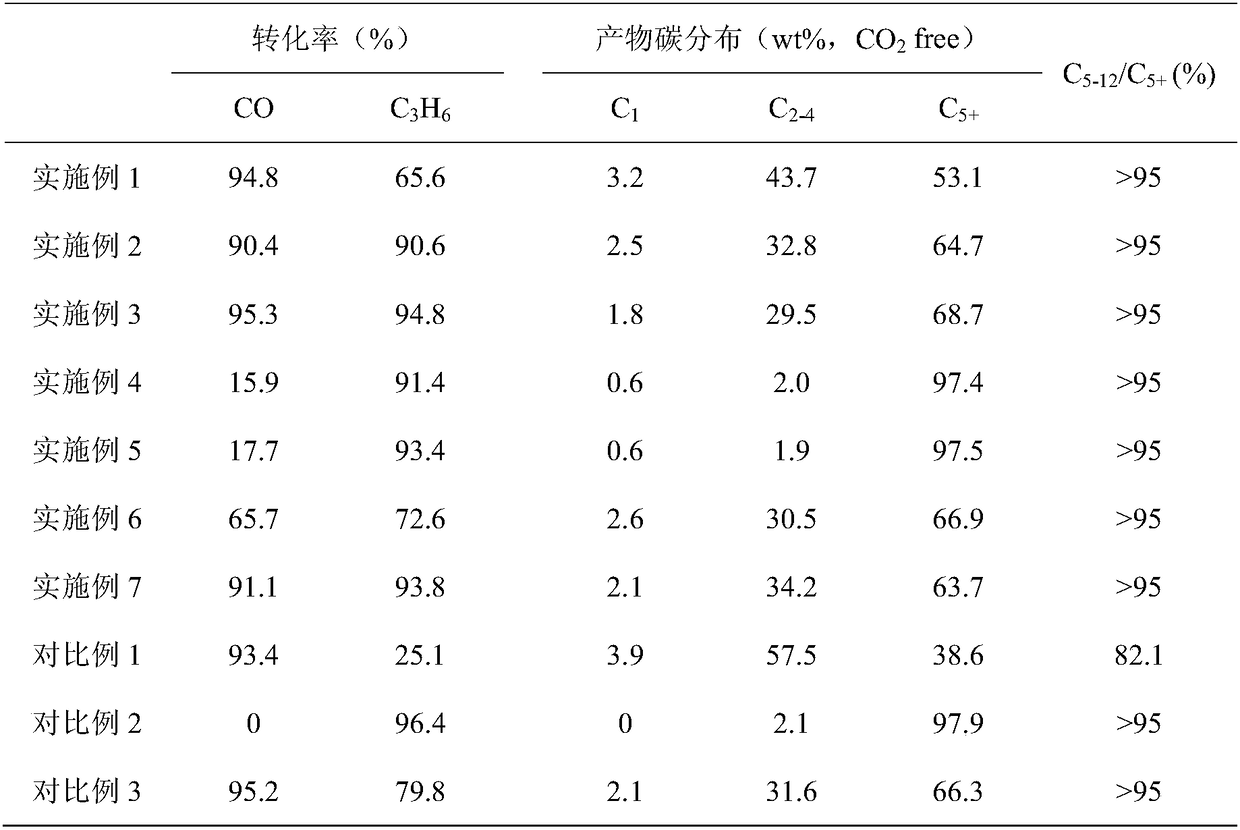

[0041] The Fe-based-molecular sieve catalyst system is realized by particle packing. Specifically as follows: the prepared Fe 3 o 4 Microsphere catalyst and nanometer HZSM-5 powder were granulated respectively to obtain particles of 40-60 mesh, and the Fe after granulation was weighed 3 o 4 and HZSM-5 particles each 0.5g, mixed uniformly to obtain a composite catalyst; 1g of Fe-based molecular sieve catalyst particles and 1g of quartz sand were mixed and packed into a fixed bed reaction tube, and the Fischer-Tropsch-oligomerization coupling reaction conditions were the same as in Example 1. The obtained oil phase product was detected by GC-MS and the statistical results were analyzed. The reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com