Quick detachment and installation type pipeline chemical reactor with continuous flow passage

A technology of chemical reactors and flow channels, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, fluid mixers, etc., can solve the problem of difficult control of reaction temperature, inconvenient disassembly and assembly, and complex structure and other problems, to achieve the effect of smooth reaction operation, beautiful appearance and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

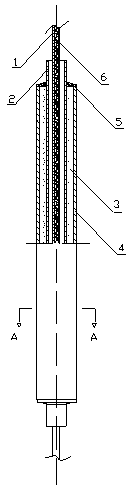

[0018] Example attached figure 1 The pipeline chemical reactor of -2 has the reaction raw material inlet and the reaction product outlet of the original tubular chemical reactor. What is different from the original chemical reactor is that it consists of reaction tube 1, temperature regulating tube 2, The insulation medium 3 and the decoration tube 4 are composed. The two ends of the reaction tube 1 are respectively connected with the reaction raw material inlet and the reaction product outlet. The mixer 6 is used to promote the uniform mixing of the reaction materials; the temperature regulation tube 2 is injected with heat / refrigerant fluid according to the needs of the chemical reaction to adjust the reaction temperature; the insulation medium layer 3 made of polypropylene plastic foam is evenly wrapped around the temperature regulation The tube 2 is made of porous fiber material to prevent heat / cold loss; the decorative tube 4 is wrapped on the outer surface of the therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com