Method for recovering aluminum hydroxide and sodium hydroxide from liquid waste of aluminum industry alkali waste

A technology of aluminum hydroxide and sodium hydroxide, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, alkali metal hydroxide, etc., can solve the problems of loss of sulfuric acid, insufficient disposal capacity, environmental hazards, etc., Achieve the effect of reducing the generation of aluminum scale, reducing the frequency of maintenance, and restoring production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

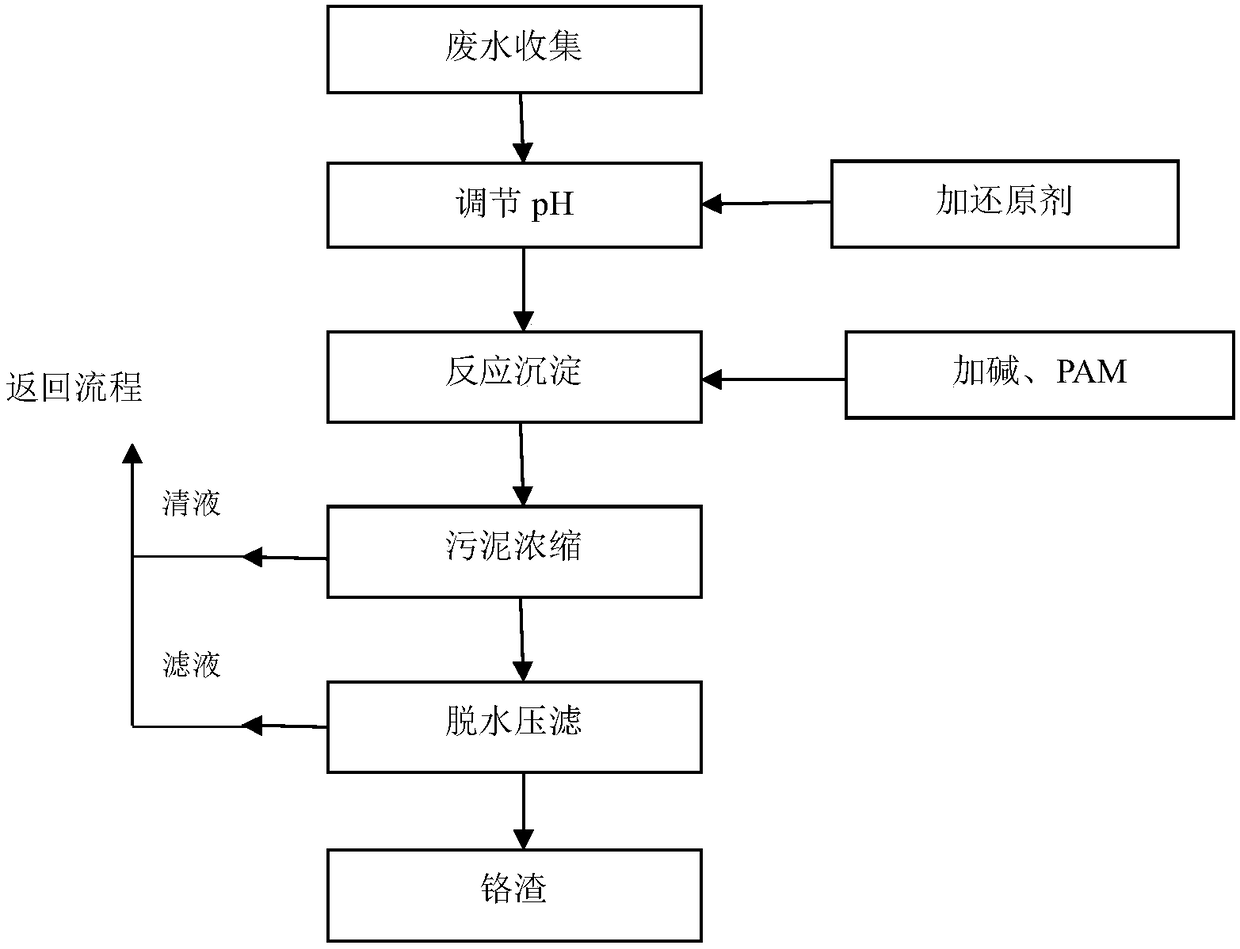

Method used

Image

Examples

Embodiment 1

[0095] Embodiment 1: get free alkali 110g / L, Al 3+ 20g / L waste liquid, R=free alkali concentration / Al 3+ Concentration = 5.50, the bath does not decompose, no aluminum hydroxide is precipitated;

Embodiment 2

[0096] Embodiment 2: get free alkali 121g / L, Al 3+ 34g / L waste liquid, R=free alkali concentration / Al 3+ Concentration = 4.0, the bath does not decompose, no aluminum hydroxide is precipitated;

Embodiment 3

[0097] Embodiment 3: get free alkali 121g / L, Al 3+ 34g / L waste liquid, R=free alkali concentration / Al 3+ Concentration = 3.56, bath does not decompose, no aluminum hydroxide precipitates;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com