Preparation method for high-strength neodymium-iron-boron alloy superfine permanent magnetic powder

A technology of NdFeB and permanent magnetic powder, which is applied in the field of preparation of high-strength NdFeB alloy ultrafine permanent magnetic powder, which can solve problems such as easy to fall off and strength that cannot meet the requirements, so as to increase the added value of products and expand the application field of products , the effect of improving the degree of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

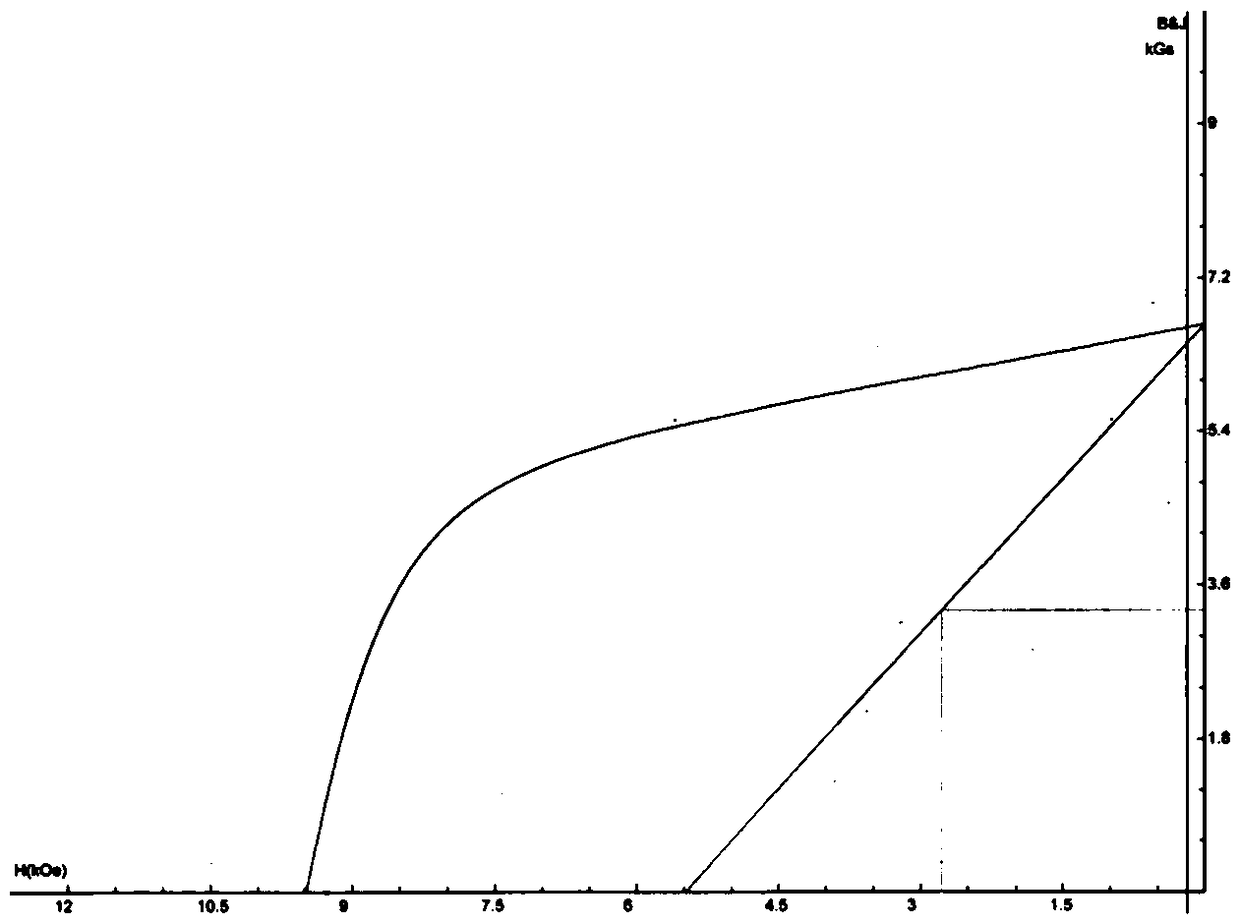

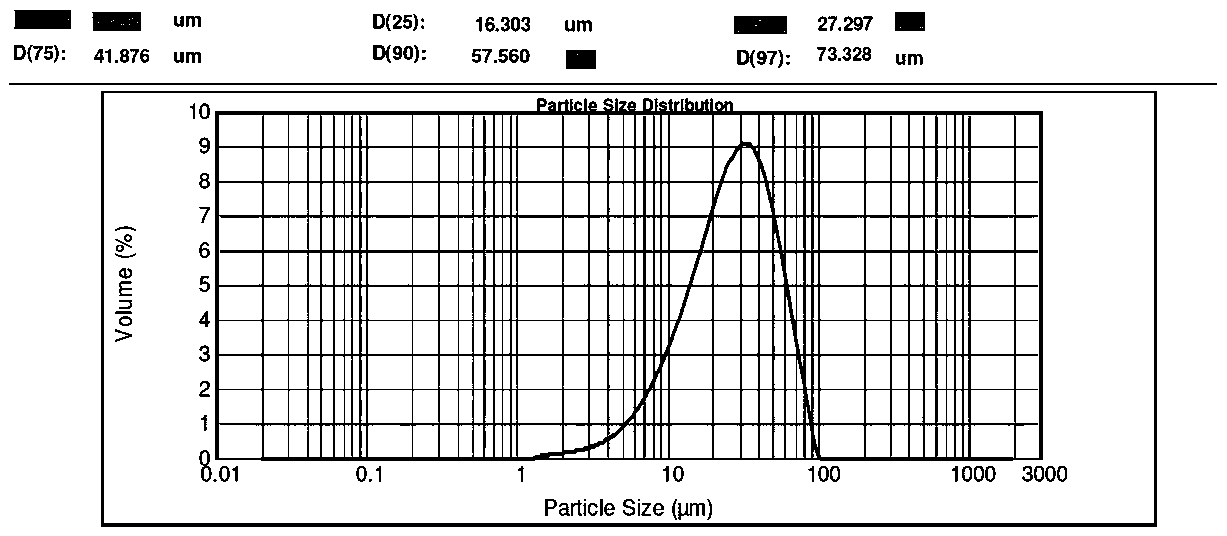

[0021] Embodiment 1, the preparation method of high-strength NdFeB alloy ultrafine permanent magnet powder, is characterized in that, the preparation method of described NdFeB alloy ultrafine permanent magnet powder successively comprises raw material selection, formula, vacuum smelting process, vacuum quick quenching process , Vacuum crystallization heat treatment process, aging process, magnetic property testing process, jet mill processing process, ultrasonic sieving particle size distribution testing process, secondary testing process of magnetic properties of finished product mixture.

[0022] The raw materials preferably selected include praseodymium-neodymium alloy, electrolytic lanthanum-cerium alloy with a purity of 45%, iron with a purity of 99.98%, iron-boron alloy with a purity of 18%, zirconium alloy with a purity of 86%, and cobalt alloy with a purity of 91%. , the weight ratio of praseodymium to neodymium of the praseodymium neodymium alloy is 20:81 or 25:76.

...

Embodiment 2

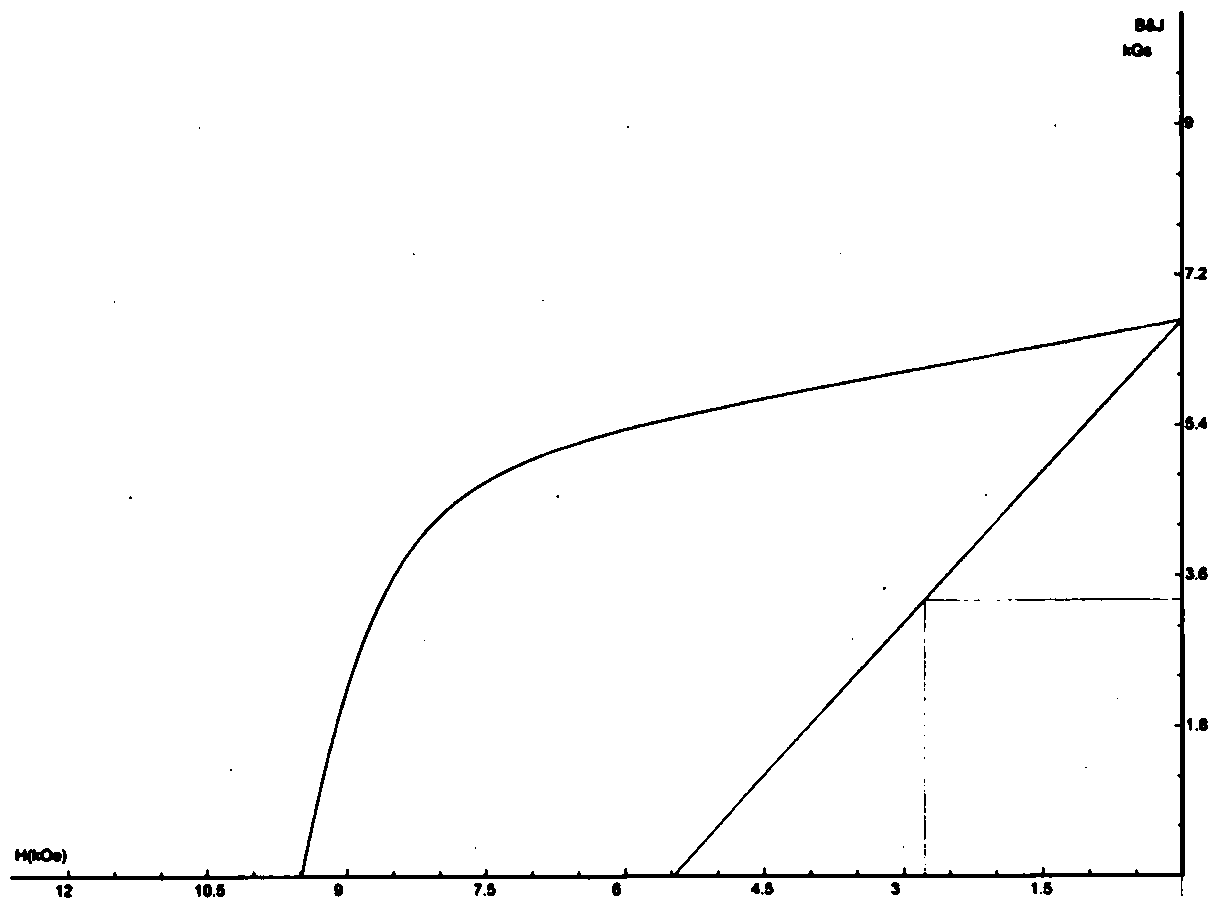

[0035] Embodiment 2 The preparation method of high-strength NdFeB alloy ultrafine permanent magnet powder, characterized in that, the preparation method of said NdFeB alloy ultrafine permanent magnet powder successively includes raw material selection, formula, vacuum smelting process, vacuum rapid quenching process, Vacuum crystallization heat treatment process, aging process, magnetic property testing process, jet mill processing process, ultrasonic sieving particle size distribution testing process, and secondary testing process of magnetic properties of finished product mixture;

[0036] The raw materials preferably selected include praseodymium-neodymium alloy, electrolytic lanthanum-cerium alloy with a purity of 80%, iron with a purity of 99.98%, iron-boron alloy with a purity of 21%, zirconium alloy with a purity of 86%, and cobalt alloy with a purity of 91%. , the weight ratio of praseodymium and neodymium of the praseodymium neodymium alloy is 20:81 or 25:76;

[0037]...

Embodiment 3

[0047] Embodiment 3, the preparation method of high-strength NdFeB alloy ultrafine permanent magnetic powder, is characterized in that, the preparation method of described NdFeB alloy ultrafine permanent magnetic powder comprises raw material selection, formula, vacuum smelting process, vacuum quick quenching process in sequence , Vacuum crystallization heat treatment process, aging process, magnetic property testing process, jet mill processing process, ultrasonic sieving particle size distribution testing process, finished product mixture magnetic property secondary testing process;

[0048] The raw materials preferably selected include praseodymium-neodymium alloy, electrolytic lanthanum-cerium alloy with a purity of 60%, iron with a purity of 99.98%, iron-boron alloy with a purity of 20%, zirconium alloy with a purity of 86%, and cobalt alloy with a purity of 91%. , the weight ratio of praseodymium and neodymium of the praseodymium neodymium alloy is 20:81 or 25:76;

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com