Fuel cell composite nano-coating and coating method thereof

A nano-coating and fuel cell technology, applied in the direction of metal material coating process, coating, sputtering plating, etc., can solve the problems of many defects in the film and the lack of better corrosion resistance of the plate, so as to reduce the Effects of deposition time, avoidance of void defects, and strengthening of bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

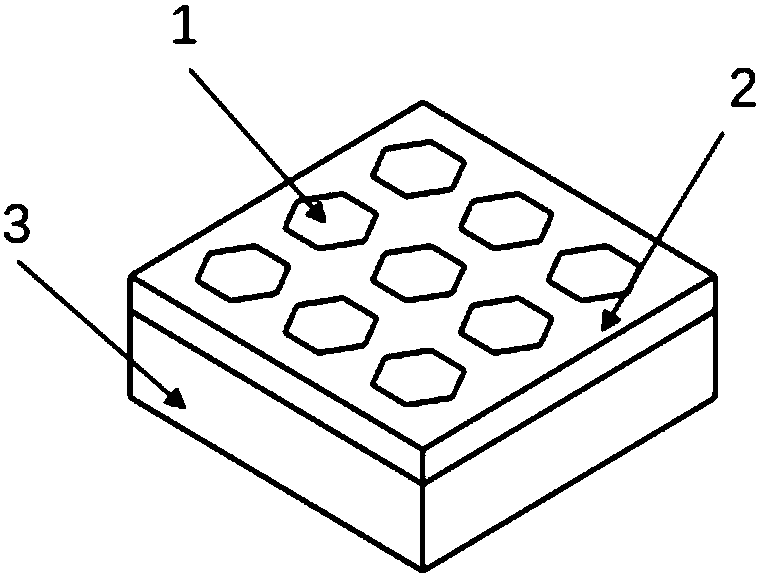

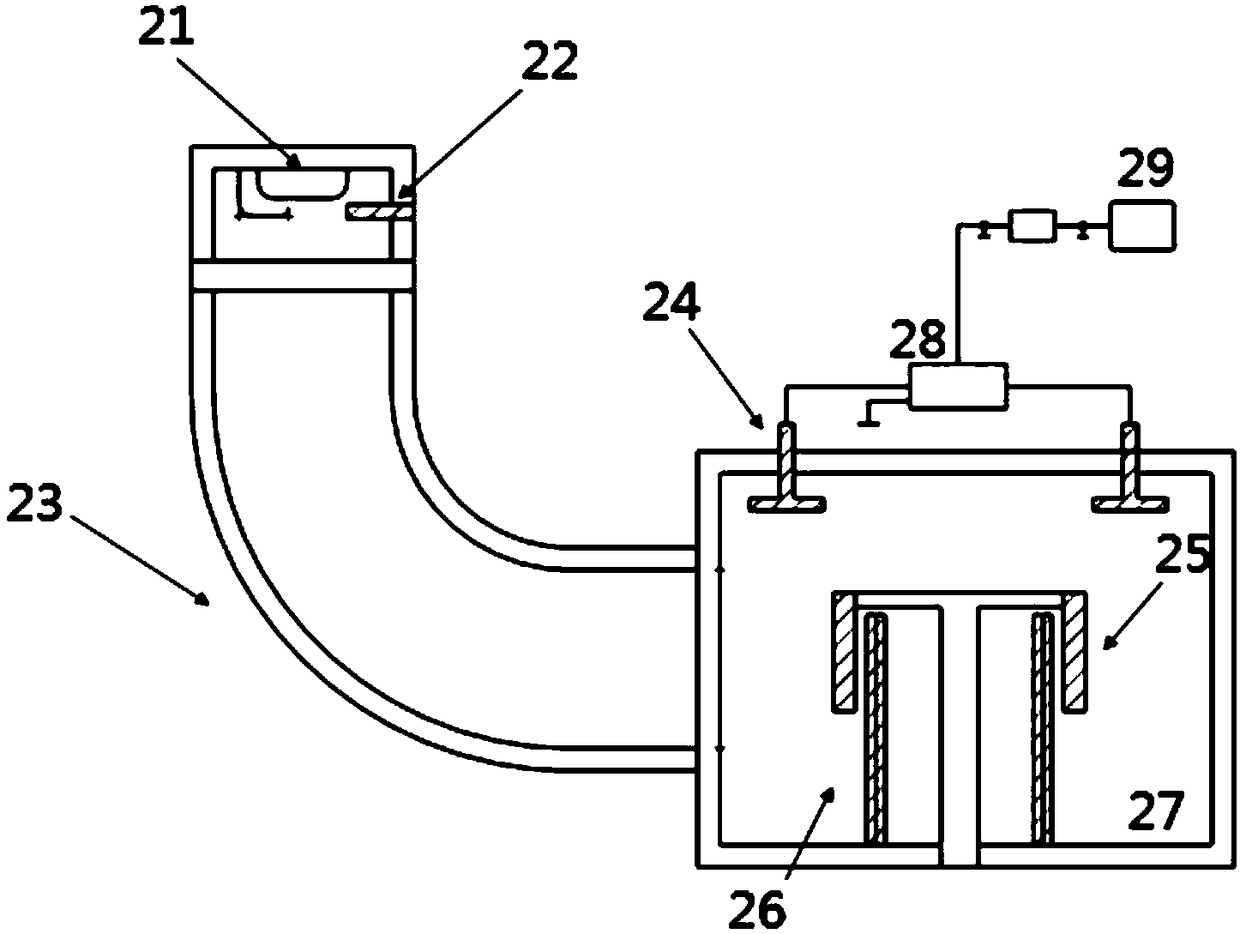

[0024] Effect of Multi-arc Ion Plating on Preparation of TiCx Amorphous Carbon Composite Coatings for Fuel Cell Plates

[0025] (1) Surface pretreatment: After cleaning the stainless steel metal plate with alkali solution and acid solution, clean it with deionized water, and then place it in absolute ethanol, acetone, and absolute ethanol for ultrasonic vibration treatment, Remove the oil on the surface of the metal plate to obtain a clean metal plate;

[0026] (2) Put the cleaned metal plate into the chamber of the multi-arc ion plating furnace, and evacuate it to less than 3×10 -5 torr, filled with argon, the working pressure is kept at 4×10 -4 torr, the base bias voltage of the metal plate is -800V, the ion source is turned on for ion bombardment to remove the passivation layer of the substrate, the ion plating sputtering cleaning process takes 30 minutes, the plate is hung on the rotating support, and the support speed is 4r / min;

[0027] (3) Control the base bias voltag...

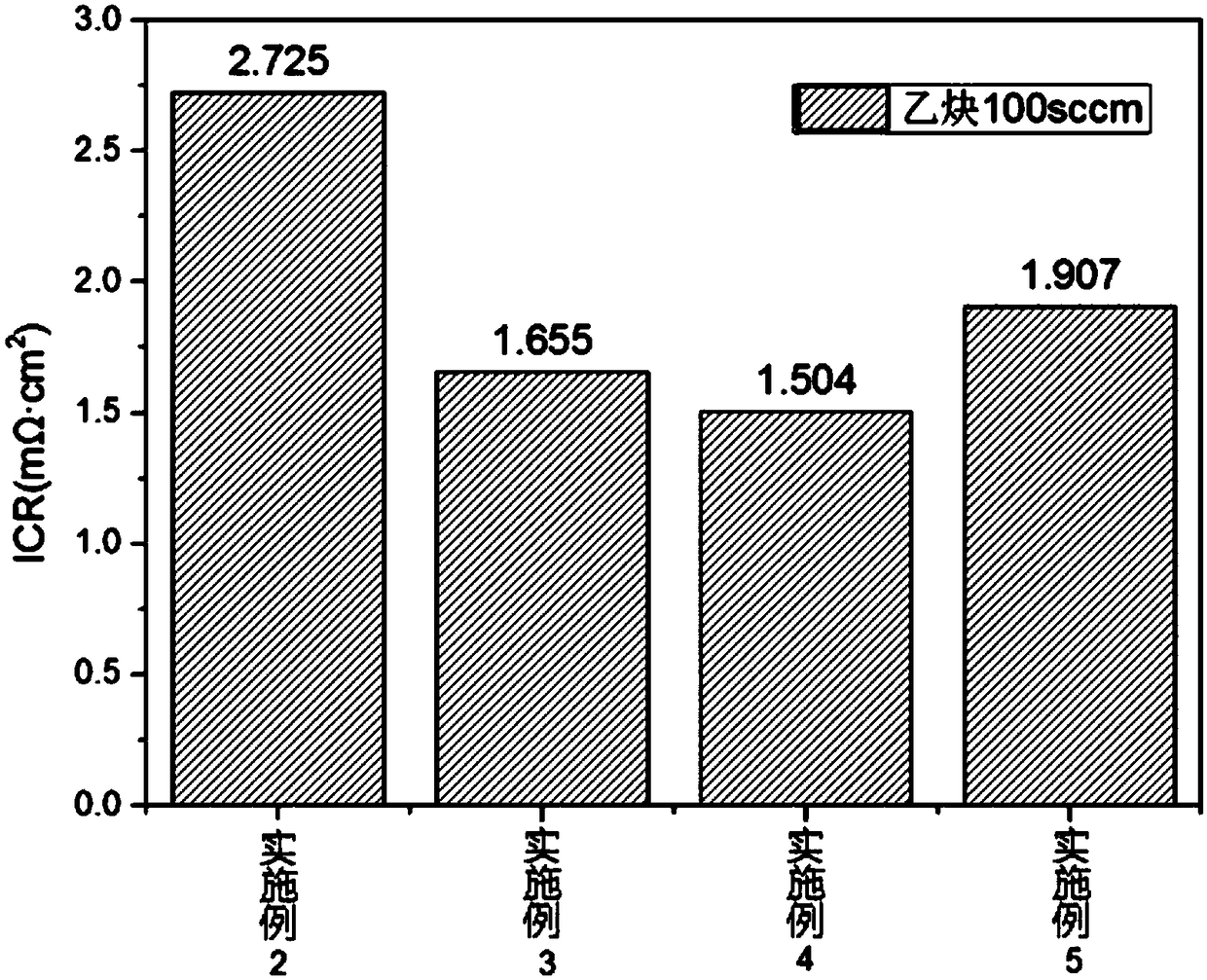

Embodiment 2

[0031] Preparation of chromium carbide amorphous carbon composite coatings for fuel cell plates by multi-arc ion plating

[0032](1) Surface pretreatment: After cleaning the stainless steel metal plate with alkali solution and acid solution, clean it with deionized water, and then place it in absolute ethanol, acetone, and absolute ethanol for ultrasonic vibration treatment, Remove the oil on the surface of the metal plate to obtain a clean metal plate;

[0033] (2) Put the cleaned metal plate into the chamber of the multi-arc ion plating furnace, and evacuate it to less than 3×10 -5 torr, filled with argon, the working pressure is kept at 4×10 -4 torr, the base bias voltage of the metal plate is -800V, the ion source is turned on for ion bombardment to remove the passivation layer of the substrate, the ion plating sputtering cleaning process takes 30 minutes, the plate is hung on the rotating support, and the support speed is 4r / min;

[0034] (3) Control the base bias volta...

Embodiment 3

[0038] Preparation of Chromium Carbide Amorphous Carbon Composite Coatings for Fuel Cell Plates by Multi-arc Ion Plating

[0039] (1) Surface pretreatment: After cleaning the stainless steel metal plate with alkali solution and acid solution, clean it with deionized water, and then place it in absolute ethanol, acetone, and absolute ethanol for ultrasonic vibration treatment, Remove the oil on the surface of the metal plate to obtain a clean metal plate;

[0040] (2) Put the cleaned metal plate into the chamber of the multi-arc ion plating furnace, and evacuate it to less than 3×10 -5 torr, filled with argon, the working pressure is kept at 4×10 -4 torr, the base bias voltage of the metal plate is -800V, the ion source is turned on for ion bombardment to remove the passivation layer of the substrate, the ion plating sputtering cleaning process takes 30 minutes, the plate is hung on the rotating support, and the support speed is 4r / min;

[0041] (3) Control the base bias volt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com