Spherical TiC powder plasma preparation method and spherical TiC powder prepared thereby

A plasma and plasma technology, which is applied in the field of metal powder preparation, can solve the problems of power instability, powder vaporization, and low yield, and achieve the effects of high spheroidization rate, difficult vaporization, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

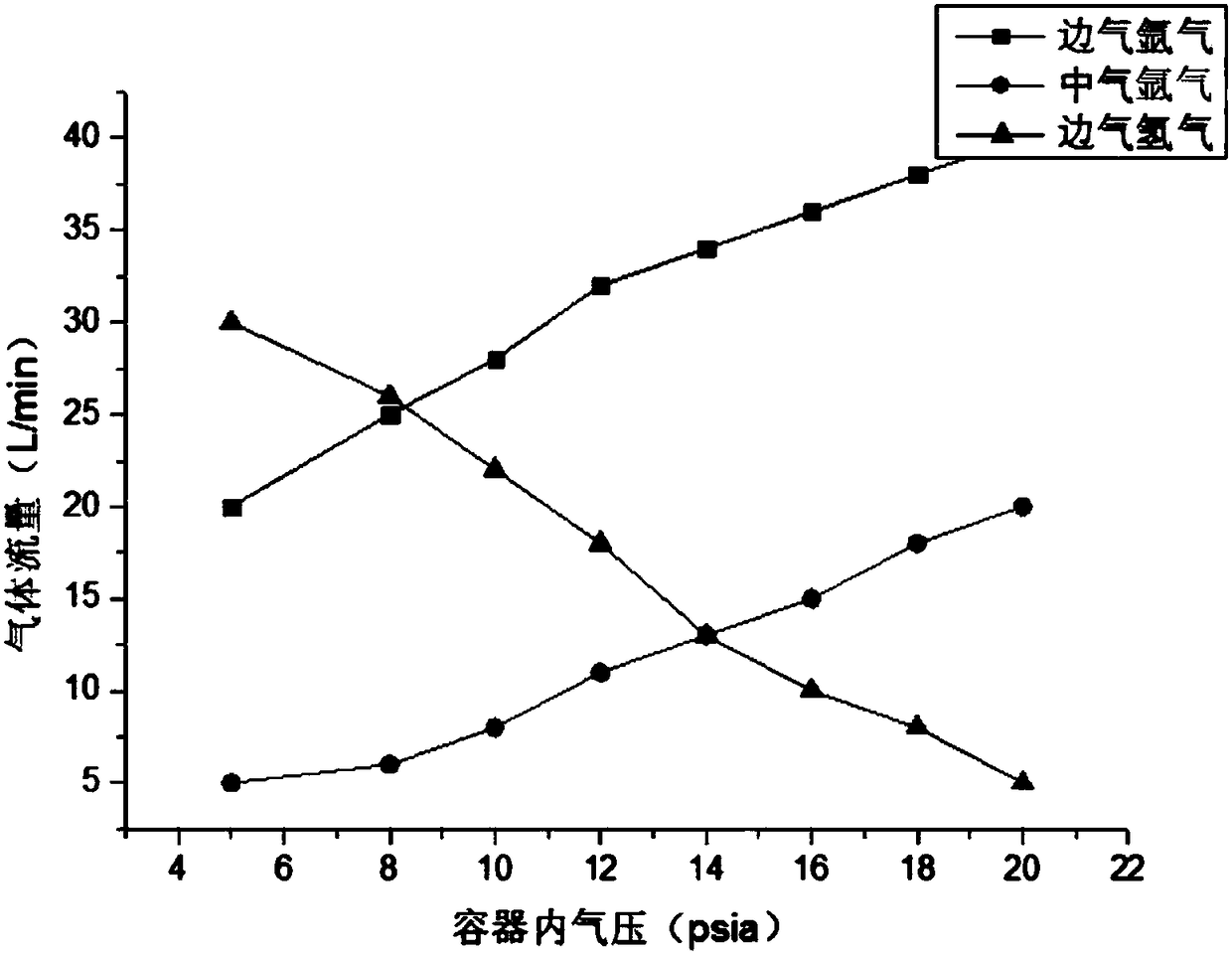

[0027] The present invention adjusts and controls air pressure and gas flow in the reaction vessel, mainly based on two parameters of gas flow and air pressure in the reaction vessel (such as figure 1 shown) for comprehensive adjustment. After research, the inventors found that in the traditional method, after the plasma is established, the pressure and gas flow in the reaction vessel are not adjusted and controlled, and the spheroidization is directly carried out. This will easily cause the TiC powder spheres to be easily vaporized and easily blown to the inner wall of the equipment. The inventor creatively adjusts the air pressure and gas flow in the container comprehensively after the plasma is ignited, so that the TiC powder balls are not easy to vaporize and are not blown to the inner wall of the equipment.

Embodiment 2

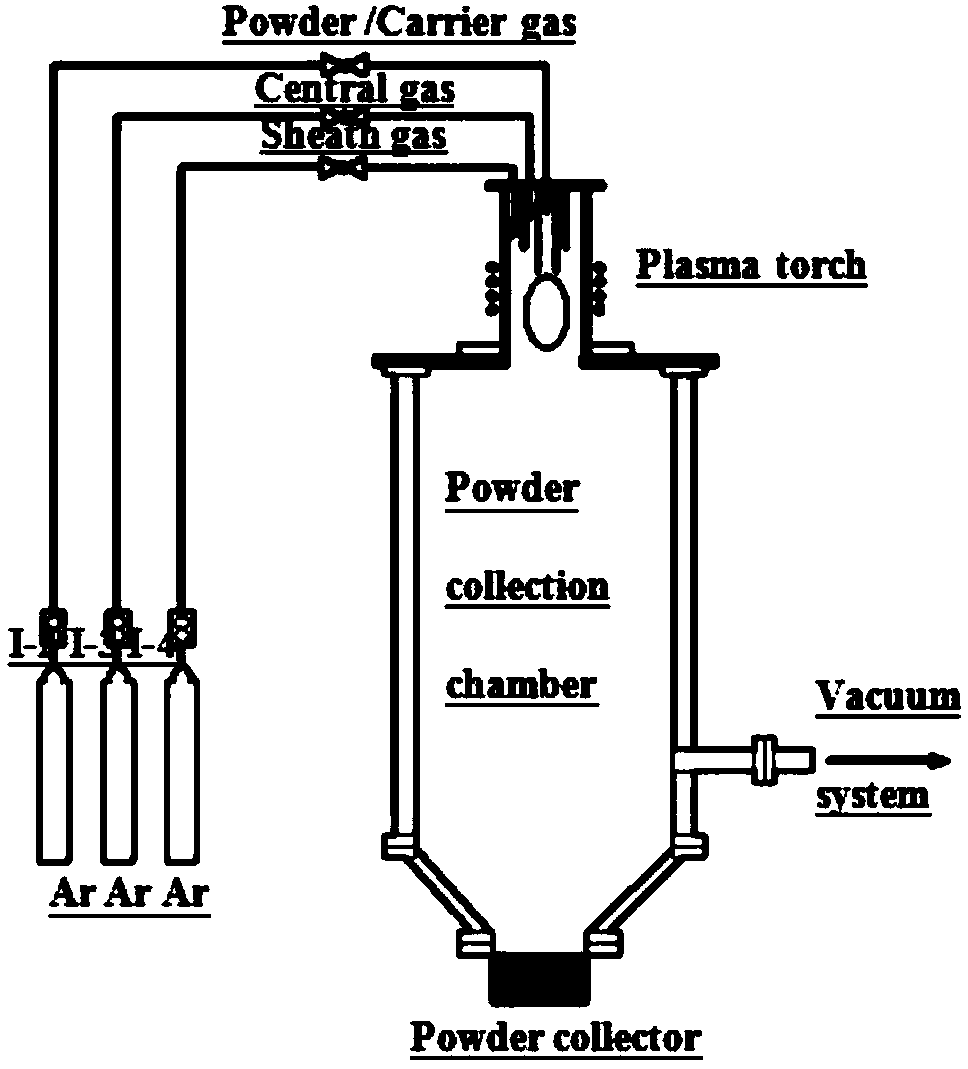

[0029] The schematic diagram of the experimental setup is as figure 2 As shown, it is composed of the following parts, the plasma reactor system, that is, the plasma generator, is used to generate the excitation electromagnetic field; the plasma torch, with side gas argon, side gas hydrogen and middle gas argon inside; powder feeding System and feeding gun; vacuum chamber; water cooling, stainless steel charging device, exhaust gas discharge system. The above-mentioned device is only a device model of the present invention, and does not limit this kind of preparation device. Any device that utilizes the principle of the present invention to prepare spherical TiC powder is within the scope of protection of the present invention.

Embodiment 3

[0031] A plasma preparation method of spherical TiC powder, comprising the following steps:

[0032] 1) Select TiC powder particles with a particle size of 40um to 50um;

[0033] 2) Perform plasma ignition; the operating parameters of plasma ignition are: the grid flow is controlled at 0.2A to 0.3A; the flow rate of argon gas in the middle gas is 5L / min; the flow rate of argon gas in the side gas is 20L / min;

[0034] 3) After successful ignition, adjusting and controlling the pressure and gas flow in the reaction vessel specifically includes: adjusting the pressure in the reaction vessel to 5 psia, adjusting the flow rate of argon gas in the middle gas to 5 L / min, adjusting the flow rate of argon gas in the side gas to 20 L / min, and adjusting the flow rate of the side gas to 20 L / min. The flow rate of gas and hydrogen is 30L / min; establish a stable argon-hydrogen plasma, and the radio frequency power is 5KW, so that TiC powder particles will not vaporize and be blown to the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com