Nanometer manganese lithium phosphate/carbon positive electrode material and preparation method thereof

A technology of lithium manganese phosphate and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of complex preparation process, high synthesis cost, unfavorable practical application, etc., and achieve simple and controllable preparation process, low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

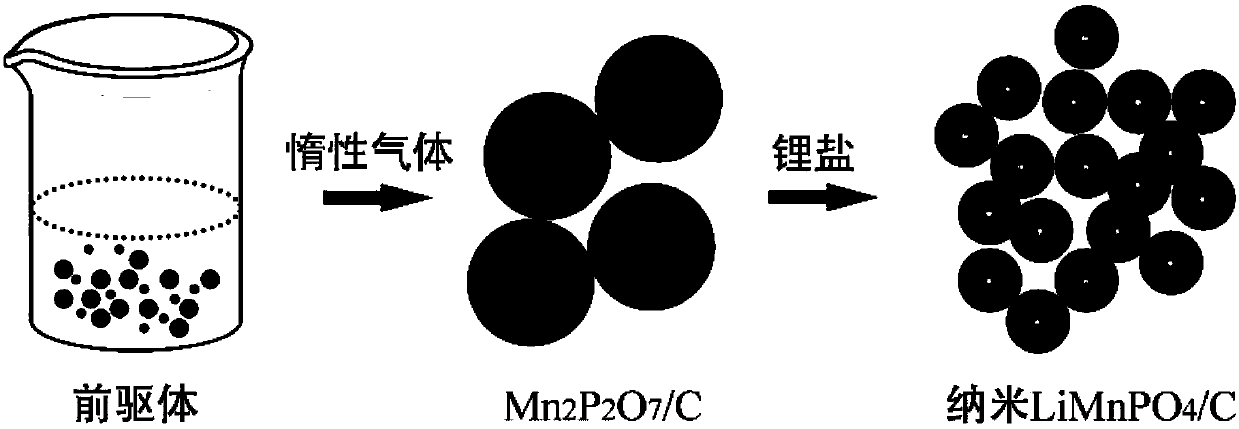

[0030] Preparation of high specific energy LiMnPO by a two-step method 4 / C nanoparticles:

[0031] Step (1), add 0.2451g manganese acetate, 0.1153g phosphoric acid (≥85wt.%) to the aqueous solution that contains citric acid (0.4202g), slowly evaporate to dryness at 70 DEG C of solvent, and in 700 DEG C of N 2 Atmosphere heat treatment for 1h, the heating rate is 10°C / min, to obtain Mn 2 P 2 o 7 / C precursor;

[0032] Step (2), Mn 2 P 2 o 7 / C precursor and lithium hydroxide were mixed uniformly according to the ratio of Mn:Li molar ratio of 1:1, and the heating rate was 10°C / min, 700°CN 2 Heat treatment under atmosphere for 10h to obtain LiMnPO 4 / C nanoparticles.

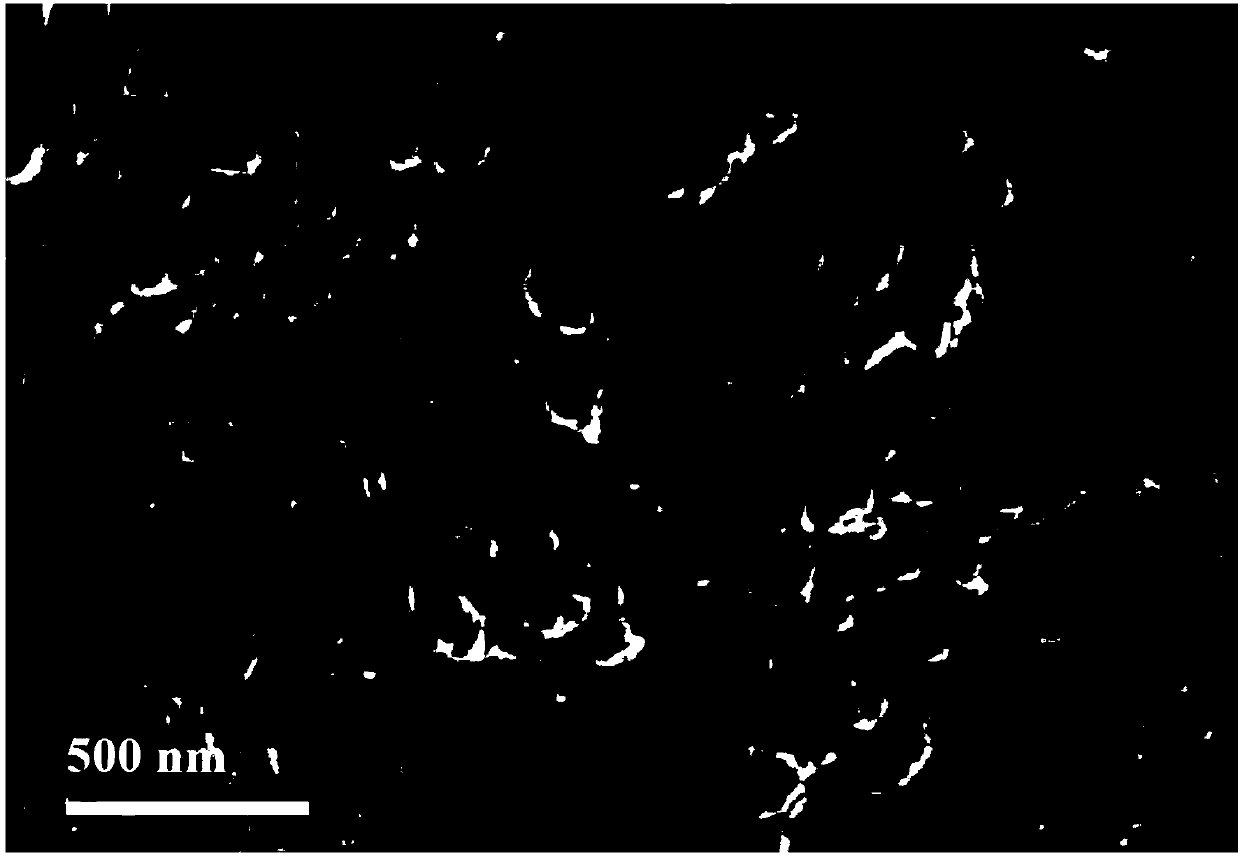

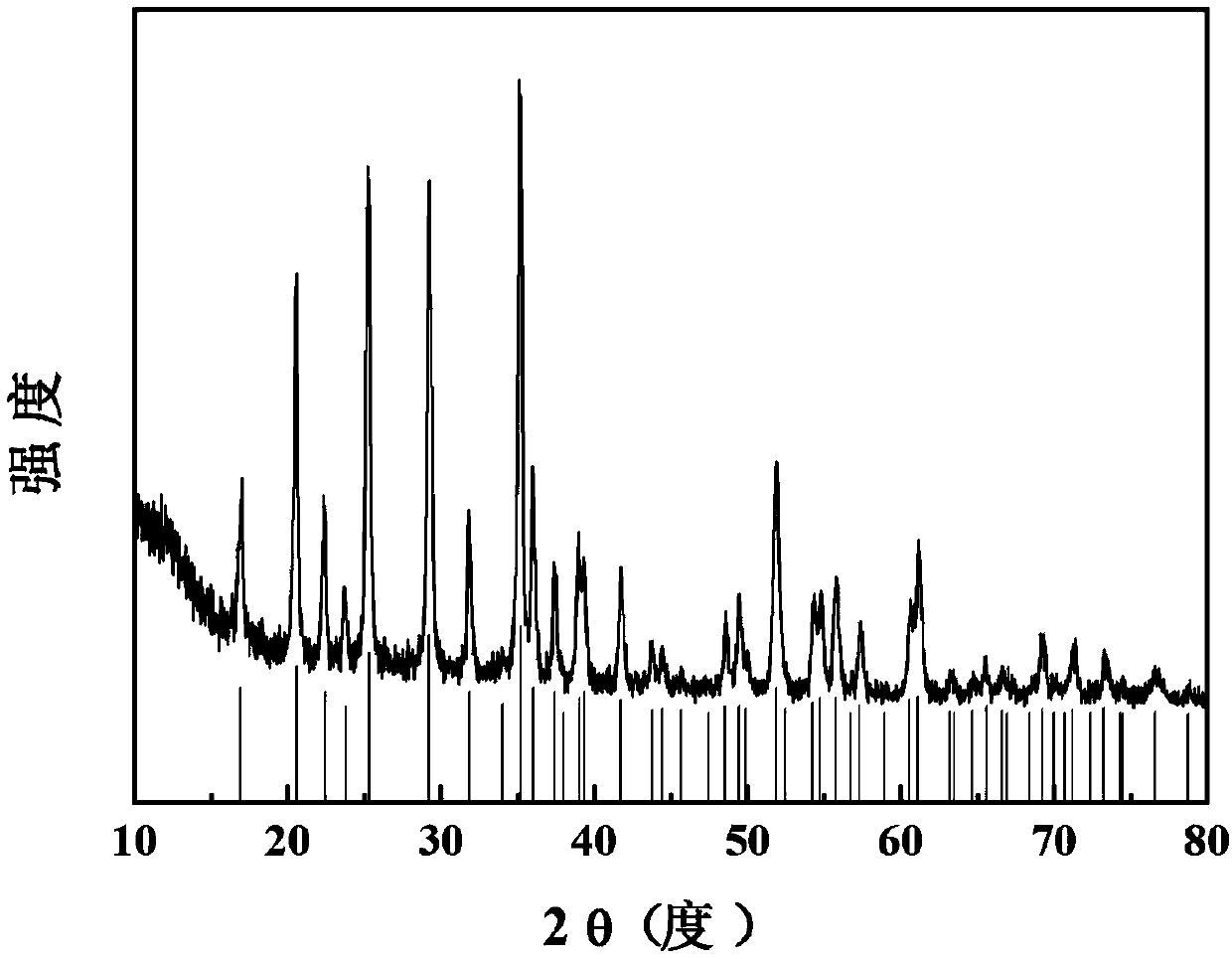

[0033] from figure 2 It can be seen that the obtained precursor Mn 2 P 2 o 7 / C has a nanoparticle structure. from image 3 It can be seen that the material obtained after lithiation is pure phase LiMnPO 4 , the crystallinity is high, and the sample is nano-morphological ( Figure 4 ).

[0034] ...

Embodiment 2

[0036] Preparation of high specific energy LiMnPO by a two-step method 4 / C nanoparticles:

[0037] Step (1), add 0.2451g of manganese acetate and 0.1151g of ammonium dihydrogen phosphate into an aqueous solution containing citric acid (0.4202g), slowly evaporate the solvent to dryness at 60°C, and heat-treat in an Ar atmosphere at 750°C for 0.5h, with a heating rate of 10°C / min, get Mn 2 P 2 o 7 / C precursor;

[0038] Step (2) Mn 2 P 2 o 7 / C precursor and lithium hydroxide were mixed evenly according to the ratio of Mn:Li molar ratio of 1:1, the heating rate was 10°C / min, and heat treatment was carried out at 800°C for 8h in Ar atmosphere to obtain LiMnPO 4 / C nanoparticles.

[0039] It can be seen from the attached figure that the precursor has a nanostructure, and the sample obtained after lithiation still maintains a nanomorphology. Prepared LiMnPO 4 The / C material exhibits excellent electrochemical performance with a carbon content of 12 wt.%. At 0.2C, the d...

Embodiment 3

[0041] Preparation of high specific energy LiMnPO by a two-step method 4 / C nanoparticles:

[0042] Step (1) Add 0.3579g of manganese nitrate (50wt.%) and 0.1151g of ammonium dihydrogen phosphate to an aqueous solution containing citric acid (0.4202g), slowly evaporate the solvent to dryness at 80°C, and heat-treat at 600°C for 2h in an Ar atmosphere. at 10°C / min to get Mn 2 P 2 o 7 / C precursor;

[0043] Step (2) Mn 2 P 2 o 7 / C precursor and lithium hydroxide were mixed evenly according to the Mn:Li molar ratio of 1:1, the heating rate was 10°C / min, and the heat treatment was carried out at 600°C for 12h in an Ar atmosphere to obtain LiMnPO 4 / C nanoparticles.

[0044] Precursor Mn 2 P 2 o 7 and lithiated LiMnPO 4 All are in the shape of nanoparticles, and the carbon content is 15wt.%. LiMnPO 4 / C material exhibits excellent electrochemical performance: at 0.1C, the discharge specific capacity is 132.6mAh g -1 ; After 50 cycles at a current density of 0.2C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com