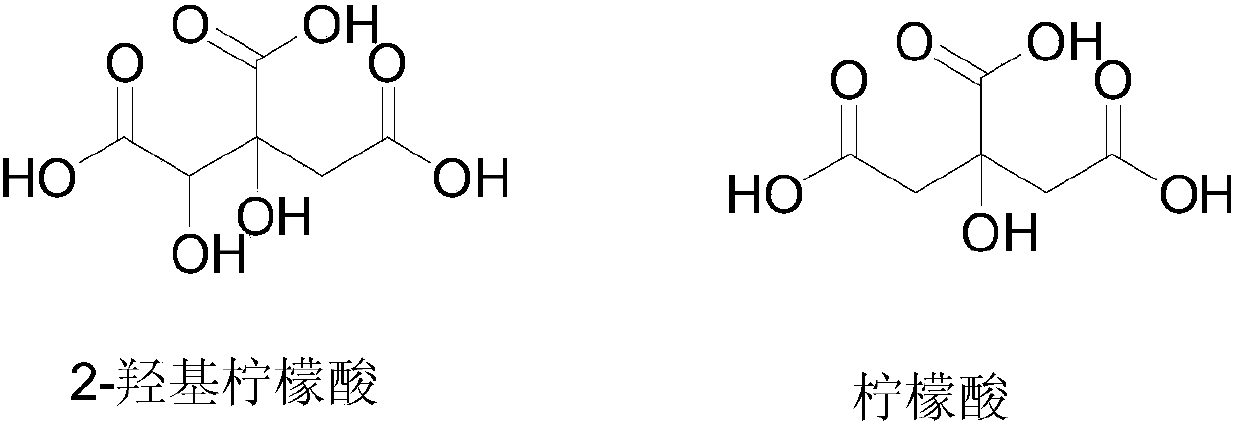

Preparation method for extracting purified hydroxy citric acid from garcinia cambogia

A technology for purifying hydroxycitric acid and hydroxycitric acid, which is applied in the field of phytochemistry, can solve the problems of high production cost, low proportion of 2-hydroxycitric acid monomer compound, and many operating procedures, and achieve low cost, convenient and efficient acquisition, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Pulverize the garcinia cambogia fruit, put it into a multi-stage countercurrent extraction device, add 4 times the volume of 2% ethanol-water solution for countercurrent extraction for 5 hours, filter after extraction, add the filtrate to a neutralization kettle, and add 1 equivalent of Calcium hydroxide aqueous solution, adjust the pH value at 7.5, stir and heat to 85 ° C, continue to stir for 2 hours, cool to at least room temperature, use an ion machine to centrifuge, wash with water to obtain the crude calcium hydroxycitrate,

[0026] Add the crude calcium hydroxycitrate to the purification kettle, add 4 times the volume of deionized water, stir, heat to 100°C, stir at 100°C for 1 hour, cool to room temperature, and perform a second centrifugation to obtain hydroxycitric acid calcium;

[0027] Add the above-mentioned purified calcium hydroxycitrate product into the acidification kettle, add 3 times the volume of deionized water, add 20% dilute sulfuric acid dropwise...

Embodiment 2

[0029] Pulverize the Garcinia cambogia fruit, put it into a multi-stage countercurrent extraction device, add 10 times the volume of 15% ethanol-water solution for countercurrent extraction for 8 hours, filter after extraction, add the filtrate to the neutralization kettle, and add 1.5 equivalents of Calcium oxide, adjust the pH value at 8.0, stir and heat to 75 ° C, continue to stir for 4 hours, cool to at least room temperature, use an ion machine to centrifuge, wash with water to obtain crude calcium hydroxycitrate,

[0030] Add the crude calcium hydroxycitrate to the purification kettle, add 8 times the volume of deionized water, stir, heat to 90°C, stir at 90°C for 2 hours, cool to room temperature, and perform a second centrifugation to obtain hydroxycitric acid calcium;

[0031] Add the above-mentioned purified calcium hydroxycitrate product into the acidification kettle, add 6 times the volume of deionized water, add 30% acid dropwise under stirring until the pH value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com