Technology for extracting ferrous sulfide from gold-bearing cyanide tailings

A technology for cyanide tailings and ferrous sulfide, which is used in solid waste removal, solid separation, flotation and other directions, can solve the problems of cyanide tailings polluting the environment, low recycling rate, etc., and achieves good cyanide removal effect. The effect of low operating cost and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

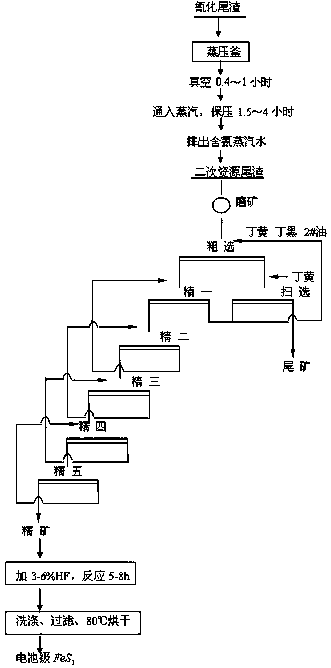

[0030] The extraction process of ferrous sulfide in gold-containing cyanide tailings comprises the following steps carried out in sequence:

[0031] 1), using autoclaved method to hydrolyze cyanide in cyanide tailings:

[0032] Before the cyanide tailings are press-filtered, impurities such as copper, lead, and zinc are removed during the cyanide gold extraction process. Press filter the cyanide tailings and install it with a bucket truck, then put the bucket truck into the autoclave, seal it and vacuumize it for 0.5 hours, then introduce steam, after the temperature rises to 170°C, start to hold the pressure for 4 hours , and then reduce the pressure to discharge steam water containing ammonia, and the tailings of secondary resources remain in the autoclave. Sodium dihydrogen phosphate and magnesium chloride are added to the obtained ammonia-containing steam water to make NH 4+ , Mg 2+ and PO 4 -3 The molar ratio is n(NH 4+ ): n (Mg2+ ): n(PO 4 -3 )=1 : 1.1 : 1; adjus...

Embodiment approach 2

[0038] The extraction process of ferrous sulfide in gold-containing cyanide tailings comprises the following steps:

[0039] 1), using autoclaved method to hydrolyze cyanide in cyanide tailings:

[0040] After the cyanide tailings are press-filtered, install them in a bucket truck, then put the bucket truck into the autoclave, seal it and vacuumize it for 0.5 hours, then put in steam, and after the temperature rises to 190°C, start to hold the pressure for 2 hours , and then reduce the pressure to discharge ammonia-containing steam water, and the remaining secondary resource cyanide tailings in the autoclave;

[0041] 2), Flotation secondary resource cyanide tailings:

[0042] Using butylamine black drug and butyl xanthate combined collector, through the process of one rough, one sweep and five fine, can obtain high-quality pyrite with a sulfur content of 52.87%, a gold content of 5.8g / t, and a purity of 99.19%. . Wherein the consumption of butylamine black medicine is 20 g...

Embodiment approach 3

[0044] The extraction process of ferrous sulfide in gold-containing cyanide tailings comprises the following steps:

[0045] 1), using autoclaved method to hydrolyze cyanide in cyanide tailings:

[0046] Press-filter the cyanidation tailings and install them with a truck, then put the truck into the autoclave, seal it and vacuumize it for 1 hour, then introduce steam, and after the temperature rises to 200°C, start to hold the pressure for 1.5 hours , and then reduce the pressure to discharge ammonia-containing steam water, and the remaining secondary resource cyanide tailings in the autoclave;

[0047] 2), Flotation secondary resource cyanide tailings:

[0048] Using butylamine black drug and butyl xanthate combined collector, through the process of one rough, one sweep and five fine, can obtain high-quality pyrite with a sulfur content of 52.87%, a gold content of 5.8g / t, and a purity of 99.19%. . Wherein the consumption of butylamine black medicine is 35 grams per ton, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com