A method for preparing a lithium-sulfur battery positive electrode material

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low battery capacity retention, battery capacity reduction, complex synthesis process, etc., to achieve good cycle stability, The effect of increased discharge capacity and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

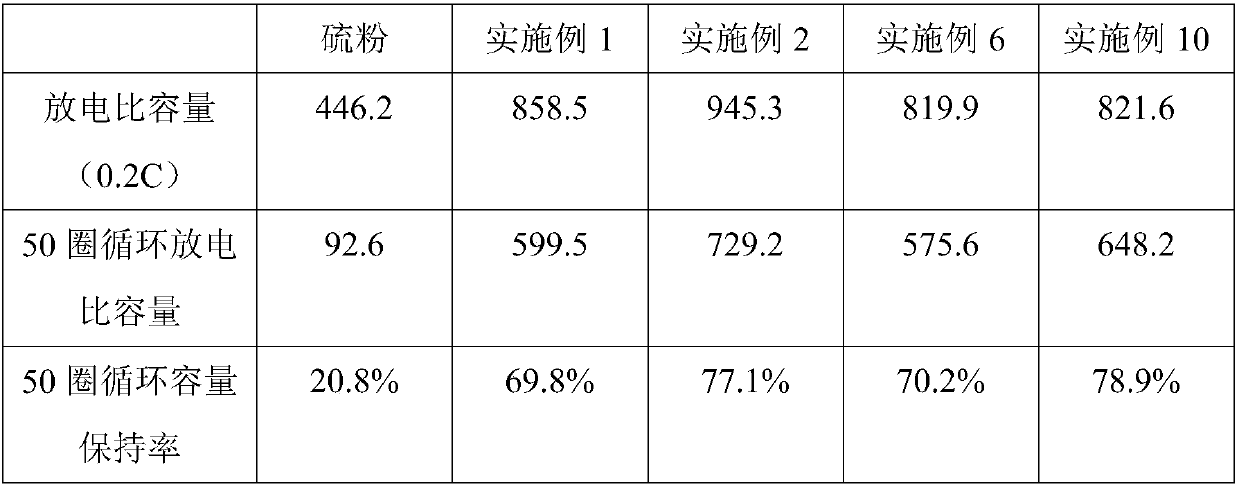

Examples

preparation example Construction

[0021] The preparation method of a kind of lithium-sulfur battery cathode material of the present invention comprises the following steps:

[0022] Step 1, sequentially add resorcinol, furfural and urotropine to the solvent for mixing, and stir for 1-3 hours;

[0023] Solvent described in step 1 is a kind of in methanol, ethanol or Virahol;

[0024] In step 1, every 100ml of solvent contains 9g-15g of resorcinol, 14ml-24ml of furfural and 0.25-1.5g of urotropine;

[0025] Step 2, sealing and heat-treating the solution obtained in step 1 at 80°C-120°C for 3 days-7 days to obtain a gel;

[0026] Step 3: heat-treat the gel obtained in step 2 at 60°C-100°C for 1 hour-5 hours, and let it stand at 25°C-50°C for 24 hours-48 hours to obtain a dry gel;

[0027] Step 4, pulverizing the xerogel obtained in step 3, and heat-treating the obtained powder under nitrogen gas at 900°C-1200°C for 2 hours-6 hours to obtain nitrogen-doped carbon airgel;

[0028] Step 5, sequentially adding hyd...

Embodiment 1

[0036] Step 1, add resorcinol, furfural and urotropine in turn to methanol and mix, stir for 1 hour, wherein every 100ml of methanol contains 9g of resorcinol, 14ml of furfural and 0.25g of urotropine Taste;

[0037] Step 2, sealing and heat-treating the solution obtained in Step 1 at 80°C for 7 days;

[0038] Step 3, heat-treating the gel obtained in step 2 at 60°C for 5 hours, and standing at 25°C for 48 hours;

[0039] Step 4, pulverizing the xerogel obtained in step 3, and heat-treating the obtained powder at 900° C. for 6 hours under nitrogen;

[0040] Step 5, sequentially add hydrochloric acid with a mass fraction of 37%, sodium thiosulfate pentahydrate, polyethylene glycol-200, and the carbon airgel obtained in step 4 to distilled water, and stir for 24 hours, wherein each 100ml of distilled water contains The mass fraction of 1.98g is 37% hydrochloric acid, 2.41g sodium thiosulfate pentahydrate, 0.2g carbon aerogel, 1ml polyethylene glycol-200;

[0041] Step 6: Soni...

Embodiment 2

[0045] Step 1, add resorcinol, furfural and urotropine to ethanol in turn and mix, stir for 3 hours, wherein every 100ml of ethanol contains 15g of resorcinol, 24ml of furfural and 1.5g of urotropine Taste;

[0046] Step 2, sealing and heat-treating the solution obtained in Step 1 at 120° C. for 3 days;

[0047] Step 3, heat-treating the gel obtained in step 2 at 100°C for 1 hour, and standing at 50°C for 24 hours;

[0048] Step 4, pulverizing the xerogel obtained in step 3, and heat-treating the obtained powder under nitrogen at 1200° C. for one hour;

[0049] Step 5, sequentially add hydrochloric acid with a mass fraction of 37%, sodium thiosulfate pentahydrate, polyethylene glycol-400, and the carbon airgel obtained in step 4 to distilled water, and stir for 48 hours, wherein each 100ml of distilled water contains The mass fraction of 11.83g is 37% hydrochloric acid, 14.47g sodium thiosulfate pentahydrate, 0.2g carbon aerogel, 5ml polyethylene glycol-400;

[0050] Step 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com