Mixed powder for powder metallurgy, sintered body, and method of manufacturing sintered body

A powder metallurgy and manufacturing method technology, applied in metal processing equipment, transportation and packaging, coating and other directions, can solve the problems of unfavorable addition, long-term sintering, uneven metal structure, etc., and achieve excellent work efficiency and high fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

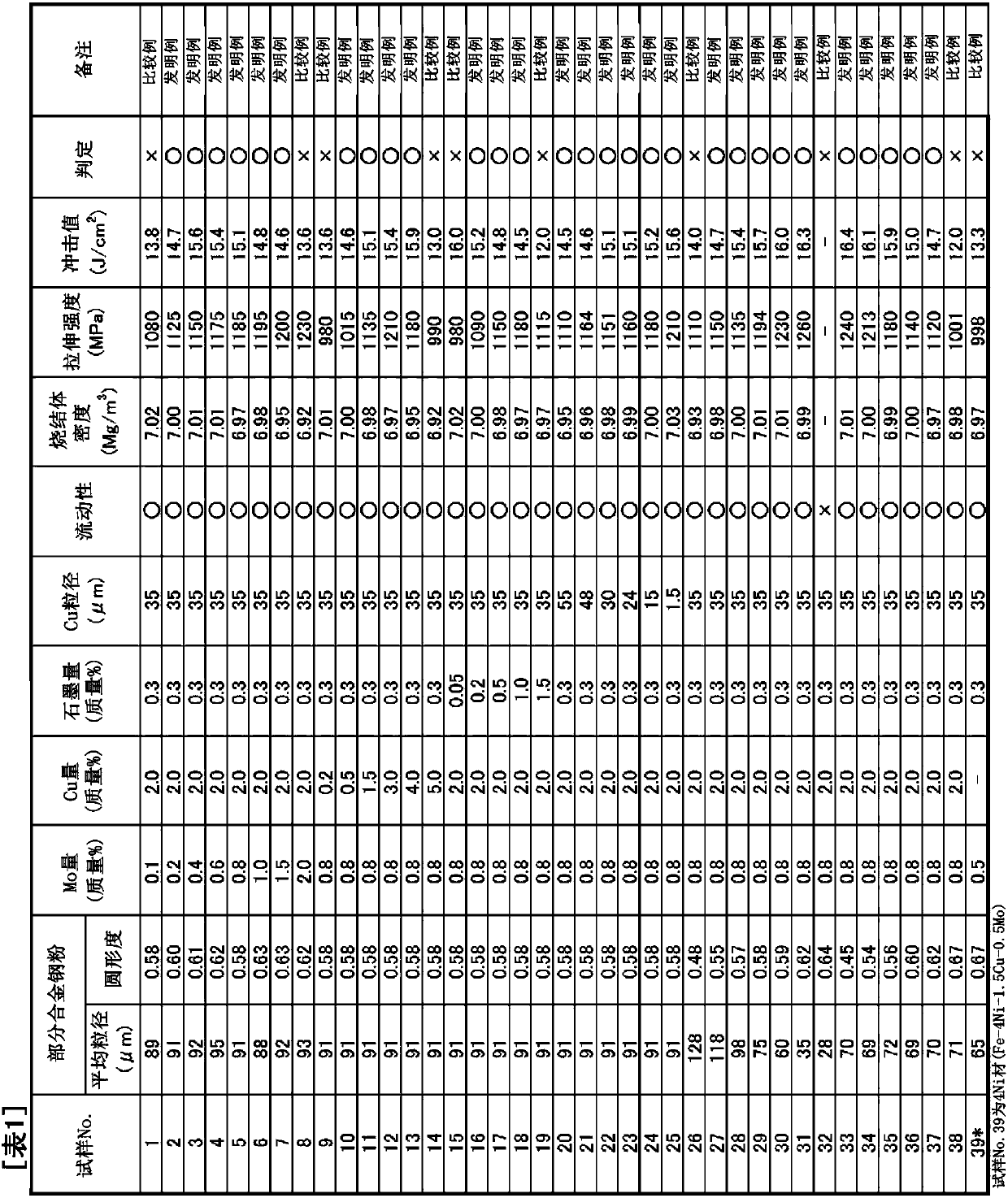

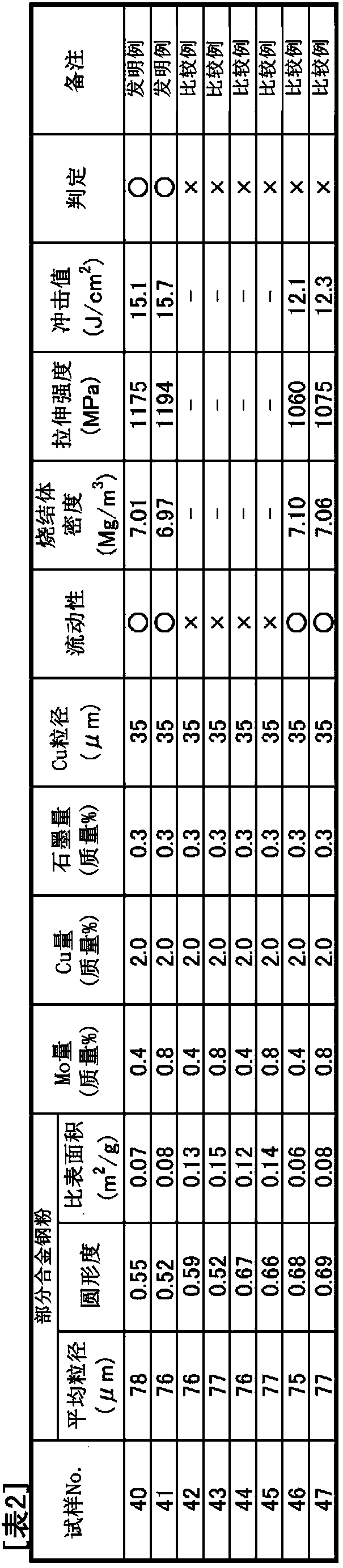

[0110] Iron-based powders use atomized raw powders with different roundness. The atomized raw powder was pulverized using a high-speed mixer (Fukae Powtec, LFS-GS-2J type), thereby varying the circularity of the atomized raw powder.

[0111] Mo oxide powder (average particle size: 10 μm) was added to the iron-based powder at a predetermined ratio, and after mixing with a V-type mixer for 15 minutes, heat treatment was performed in a hydrogen atmosphere with a dew point of 30°C (holding temperature: 880°C, Holding time: 1 hour), and a partial alloy steel powder in which a predetermined amount of Mo shown in Table 1 was diffusely adhered to the particle surface of the iron-based powder was produced. In addition, as shown in sample No. 1-8 of Table 1, Mo amount was changed variously.

[0112] Part of the produced alloy steel powder was embedded in resin, and ground to expose a part of the cross section of the alloy steel powder. It should be noted that part of the alloy steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com