Method for preparing automobile hub high-temperature phosphating solution

A technology of automobile wheel hub and phosphating liquid, applied in the direction of metal material coating process, etc., can solve the problem of slow phosphating speed, and achieve the effect of improving phosphating efficiency, fast forming speed and increasing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

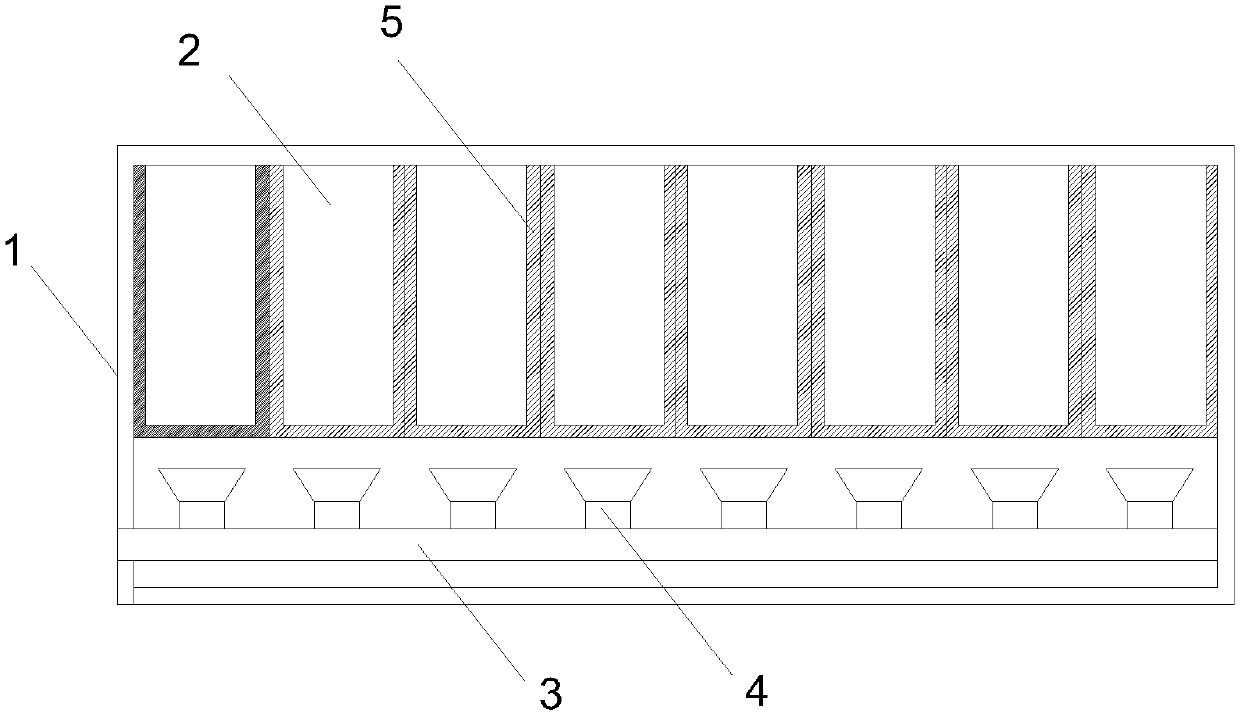

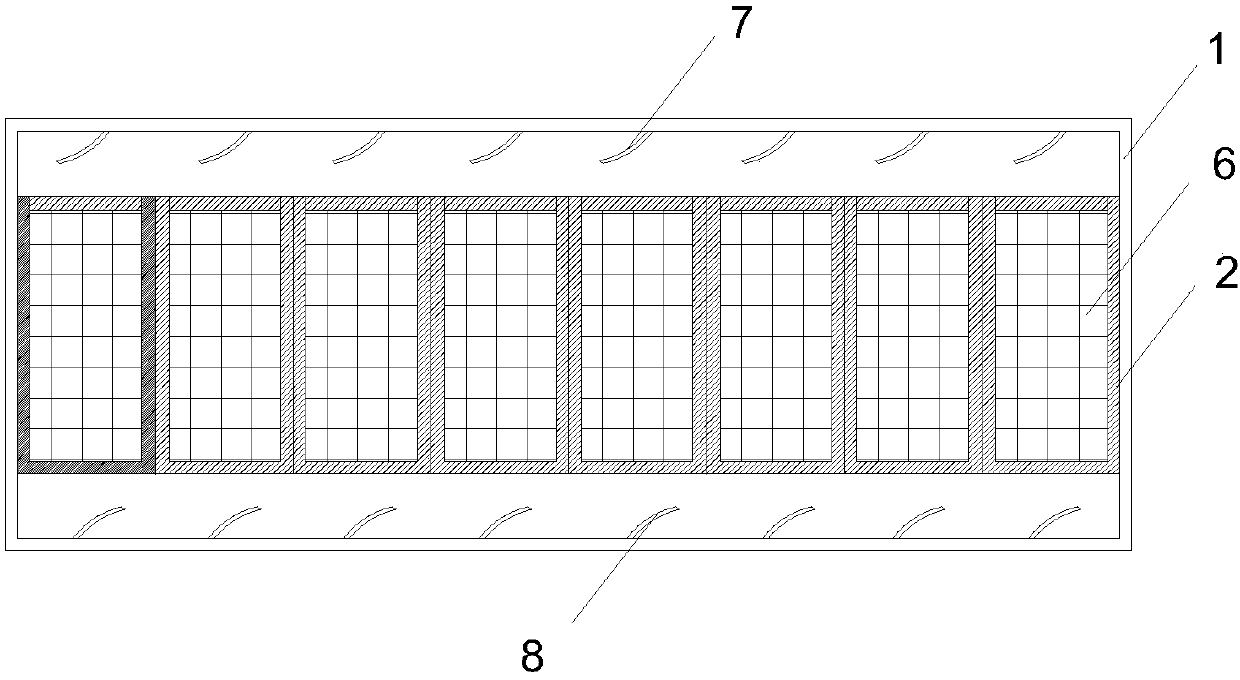

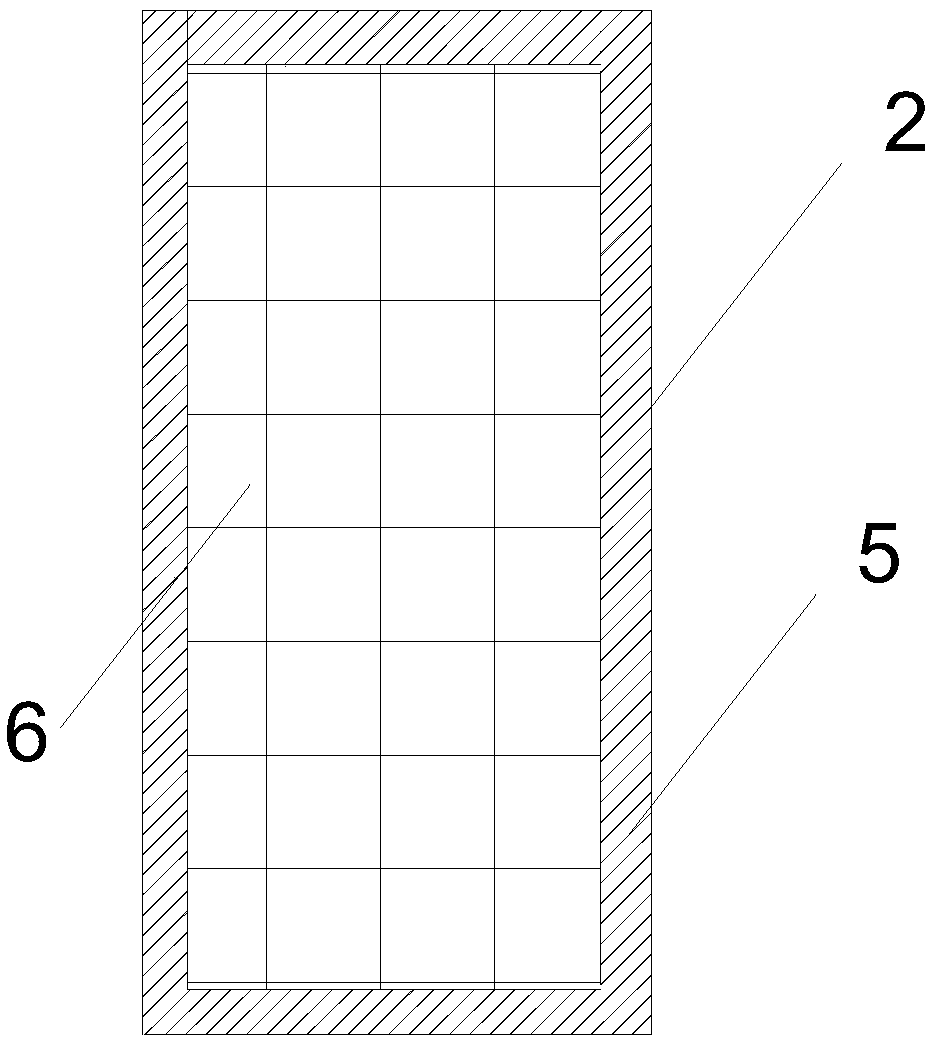

Image

Examples

Embodiment 1

[0047] A preparation method of a high-temperature phosphating solution for an automobile wheel hub: comprising the following steps:

[0048] (1) Raise the temperature of the reactor to 70°C, then pass in nitrogen gas, and seal it for storage, then stop the heating, seal it for 30-40 minutes, open the lid and cool down until the temperature in the kettle is 50°C;

[0049] (2) Add phosphoric acid, zinc nitrate, thiourea, zinc oxide, oxalic acid, sodium fluoride, and nickel nitrate to the reactor in sequence, turn on the stirring function of the reactor, stir at a constant speed for 30 seconds, then quickly add ethanol, heat up to 65°C after sealing and stir 20min;

[0050] (3) Mix citric acid, ammonium fluozirconate, hydrofluoric acid, boric acid, ethylenediaminetetraacetic acid, zinc molybdate, tartaric acid, and accelerators together to sterilize them with ultraviolet rays, and then put them in a refrigerator for low-temperature refrigeration for 1 hour;

[0051] (4) Add the ra...

Embodiment 2

[0056] A preparation method of a high-temperature phosphating solution for an automobile wheel hub: comprising the following steps:

[0057] (1) Raise the temperature of the reactor to 75°C, then pass nitrogen gas into it, and seal it for storage, then stop heating, seal it for 30-40 minutes, open the lid and cool down until the temperature in the kettle is 55°C;

[0058] (2) Add phosphoric acid, zinc nitrate, thiourea, zinc oxide, oxalic acid, sodium fluoride, and nickel nitrate to the reactor in turn, turn on the stirring function of the reactor, stir at a constant speed for 40 seconds, then quickly add ethanol, heat up to 65°C after sealing and stir 25min;

[0059] (3) After mixing citric acid, ammonium fluozirconate, hydrofluoric acid, boric acid, ethylenediaminetetraacetic acid, zinc molybdate, tartaric acid, and accelerators, carry out ultraviolet sterilization, and then refrigerate at low temperature in a refrigerator for 1.5 hours;

[0060] (4) Add the raw material co...

Embodiment 3

[0065] A preparation method of a high-temperature phosphating solution for an automobile wheel hub: comprising the following steps:

[0066] (1) Raise the temperature of the reactor to 75°C, then pass in nitrogen gas, and seal it for storage, then stop heating, seal it for 30-40 minutes, open the lid and cool down until the temperature in the kettle is 50°C;

[0067] (2) Add phosphoric acid, zinc nitrate, thiourea, zinc oxide, oxalic acid, sodium fluoride, and nickel nitrate to the reactor in turn, turn on the stirring function of the reactor, stir at a constant speed for 35 seconds, then quickly add ethanol, heat up to 65°C after sealing and stir 23min;

[0068] (3) Mix citric acid, ammonium fluozirconate, hydrofluoric acid, boric acid, ethylenediaminetetraacetic acid, zinc molybdate, tartaric acid, and accelerants together to sterilize them with ultraviolet rays, and then put them in a refrigerator for low-temperature refrigeration for 1 hour;

[0069] (4) Add the raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com