Phosphated stainless steel material and its preparation method and application

A technology of stainless steel and 304 stainless steel, applied in metal material coating process, solid-state diffusion coating, coating, etc., can solve the problems of high cost, poor phosphating efficiency, and consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

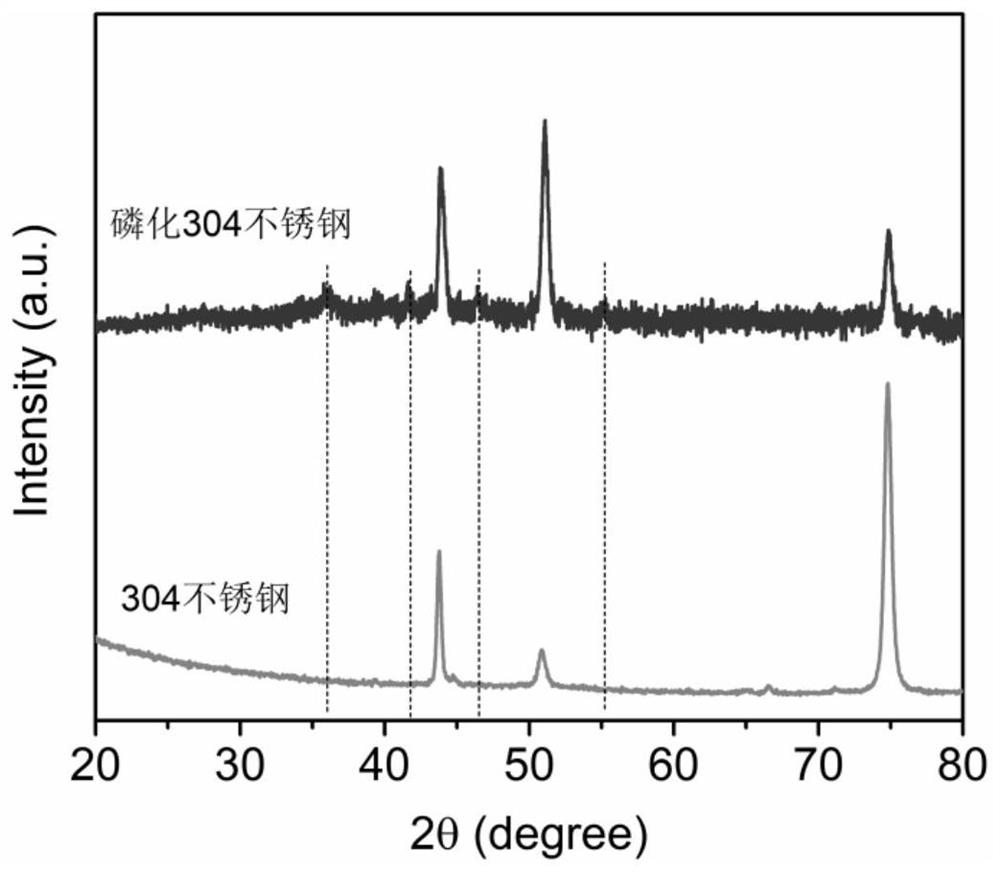

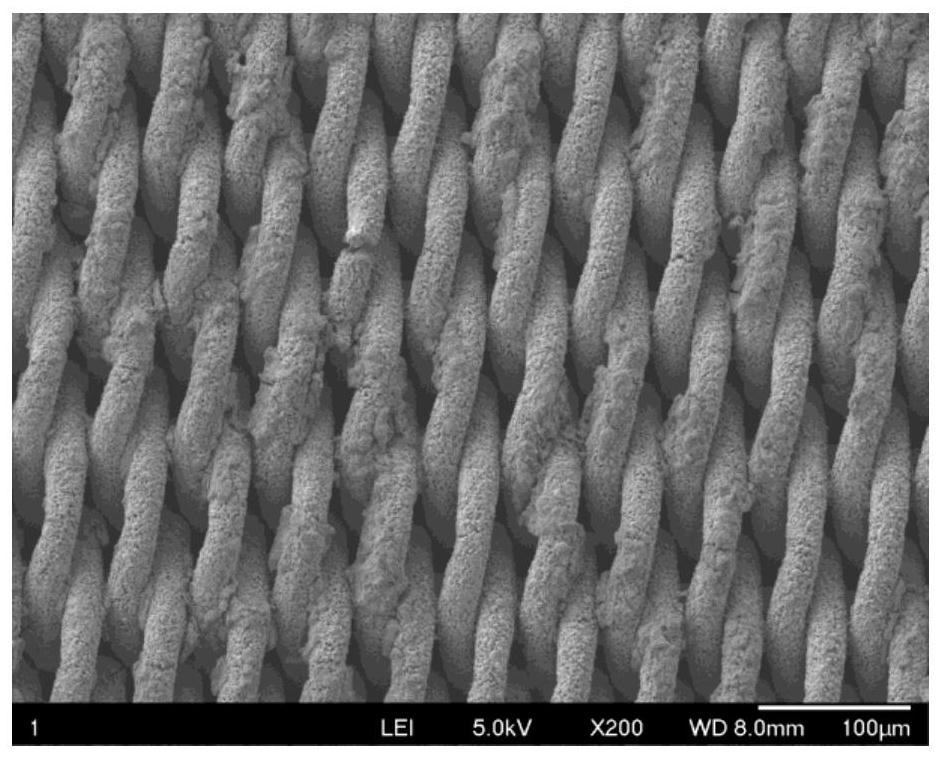

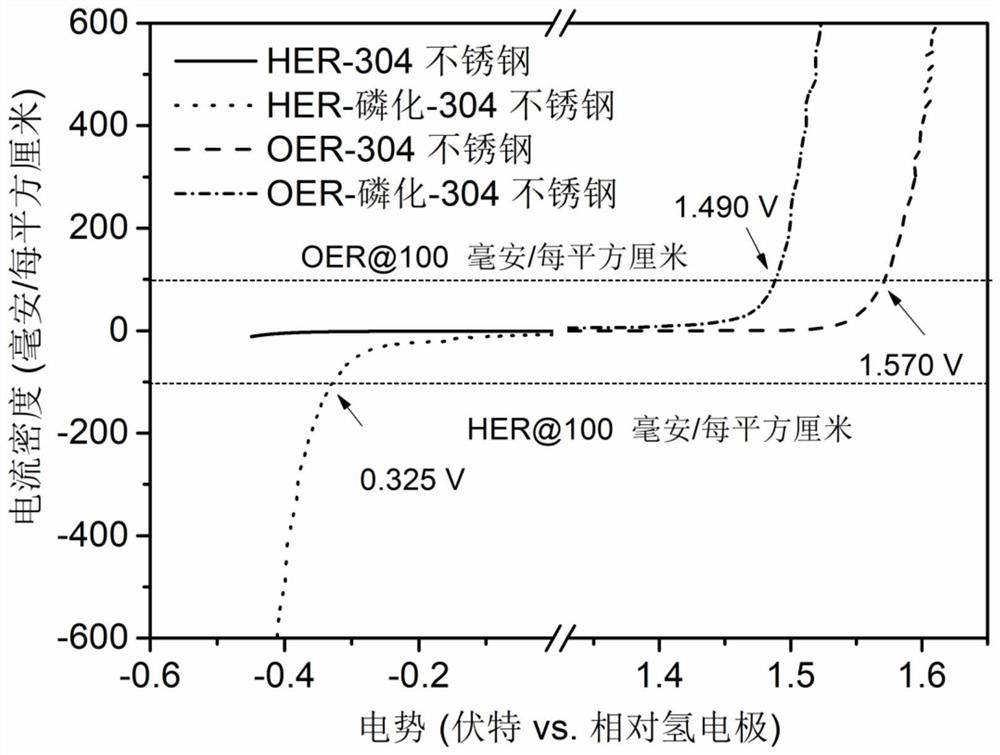

Embodiment 1

[0025] The area of 2 pieces is 2X 2.3cm respectively 2 The stainless steel 304 material and 100ul phosphorus trichloride were put into a quartz tube, vacuum sealed in a liquid nitrogen environment, and then put into a tube furnace, and calcined at 650 ° C for 1 h to obtain the phosphating stainless steel material. Tested in 1M KOH, the OER performance of the phosphating stainless steel electrode is 100mA / cm 2 Under the current density, the overpotential is only 260mV, and the HER performance is 100mA / cm in 1MKOH 2 Under the current density, the overpotential is only 325mV.

Embodiment 2

[0027] The area of 2 pieces is 2X 2.3cm respectively 2 The stainless steel 304 material and 100ul of phosphorus trichloride were put into a quartz tube, vacuum sealed in a liquid nitrogen environment, and then put into a tube furnace, and calcined at 700 ° C for 1 hour to obtain the phosphating stainless steel material. Tested in 1M KOH, the OER performance of the phosphating stainless steel electrode is 100mA / cm 2 Under current density, the overpotential is only 300mV, and the HER performance is 100mA / cm in 1MKOH 2 Under the current density, the overpotential is only 307mv.

Embodiment 3

[0029] The area of 2 pieces is 2X 2.3cm respectively 2 The stainless steel 304 material and 100ul of phosphorus trichloride were put into a quartz tube, vacuum sealed in a liquid nitrogen environment, and then put into a tube furnace, and calcined at 600 ° C for 1 hour to obtain the phosphating stainless steel material. Tested in 1M KOH, the OER performance of the phosphating stainless steel electrode is 100mA / cm 2 Under current density, the overpotential is only 330mV, and the HER performance is 100mA / cm in 1MKOH 2 Under the current density, the overpotential is only 300mv.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com