Flame-retardant flexible sound-insulating material as well as preparation method and application thereof

A sound insulation material and flexible technology, applied in the field of flame retardant flexible sound insulation material and its preparation, can solve the problems of limited use, black color, choking and toxic gas, etc., and achieve easy installation and disassembly, light weight and good sound insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

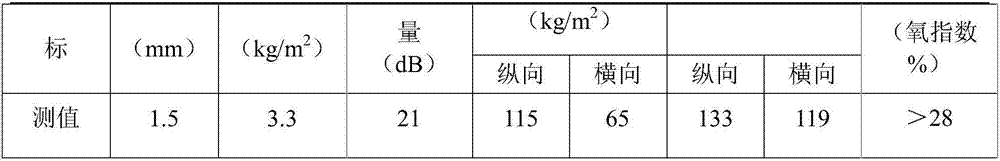

Embodiment 1

[0034] A method for preparing a flame-retardant flexible sound-insulating material of the present invention, comprising the following steps:

[0035] (1) Weigh raw materials according to the following weight ratio: 30 parts of EPDM, 20 parts of polypropylene, 5 parts of carbon fiber, 15 parts of ultrafine metal iron powder (2 μm), 15 parts of dioctyl adipate, hydrogenated 5 parts of aluminum, 2 parts of calcium zinc powder, 2 parts of dibenzothiazole disulfide, 2 parts of sublimed sulfur, 2 parts of silane coupling agent (KH570), 2 parts of nano silver.

[0036] (2) Pre-vulcanization treatment: Put EPDM, polypropylene, dioctyl adipate, and calcium-zinc powder into an open mixer (at a temperature of 160°C and at a speed of 20r / min) and knead for 2 minutes. Add carbon fiber, superfine metal iron powder, aluminum hydroxide and silane coupling agent (KH570), and continue kneading for 5 minutes.

[0037] (3) Vulcanization treatment: After the mixture is cooled to room temperature,...

Embodiment 2

[0044] A method for preparing a flame-retardant flexible sound-insulating material of the present invention, comprising the following steps:

[0045] (1) Weigh raw materials according to the following weight ratio: 35 parts of EPDM, 20 parts of polypropylene, 5 parts of aluminum fiber, 10 parts of ultrafine metal iron powder (2 μm), 15 parts of dioctyl phthalate, 5 parts of aluminum hydroxide, 2 parts of organic antimony, 2 parts of dibenzothiazole disulfide, 2 parts of sublimed sulfur, 2 parts of silane coupling agent (KH570), 2 parts of nano silver.

[0046] (2) Pre-vulcanization treatment: first put EPDM, polypropylene, dioctyl phthalate, and organic antimony into an open mixer (at a temperature of 160°C and at a speed of 20r / min) and knead for 2 minutes, then add Aluminum fiber, superfine metal iron powder, aluminum hydroxide and silane coupling agent (KH570), continue kneading for 5 minutes.

[0047] (3) Vulcanization treatment: After the mixture is cooled to room temper...

Embodiment 3

[0053] A method for preparing a flame-retardant flexible sound-insulating material of the present invention, comprising the following steps:

[0054] (1) Weigh raw materials according to the following weight ratio: 35 parts of butadiene rubber, 15 parts of polyurethane, 5 parts of aluminum fiber, 15 parts of ultrafine graphene powder (200nm), 15 parts of dioctyl adipate, zinc borate 5 parts, calcium zinc powder 2 parts, dibenzothiazole disulfide 2 parts, sublimated sulfur 2 parts, silane coupling agent (KH570) 2 parts, nano silver 2 parts.

[0055] (2) Pre-vulcanization treatment: Put butadiene rubber, polyurethane, dioctyl adipate, and calcium-zinc powder into an open mill (at a temperature of 160°C and at a speed of 20r / min) and knead for 2 minutes, then add aluminum fiber , ultrafine graphene powder and chromium complex coupling agent, continue to knead for 5min.

[0056] (3) Vulcanization treatment: After the mixture is cooled to room temperature, add sublimated sulfur, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com