Down-conversion luminescent material with broad band absorption and preparation method thereof

A luminescent material and wide-band technology, which is applied in the field of down-conversion luminescent material with broad-band absorption and its preparation, can solve the problems of insignificant improvement in energy conversion efficiency, weak near-infrared light emission intensity, and low absorption capacity. Achieve the effect of low cost, stable properties and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

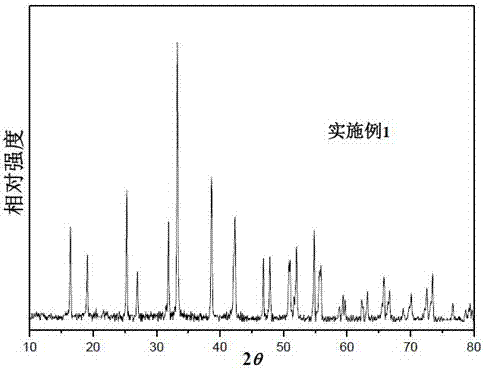

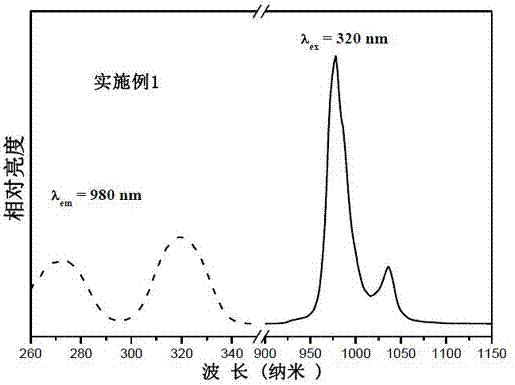

[0023] Weigh 2.7210g of boric acid, 1.6314g of gadolinium oxide, 1.5294g of aluminum oxide, 0.0985g of ytterbium oxide and 0.0861g of cerium oxide, grind them evenly in an agate mortar, put them into a corundum crucible, put them into a high-temperature furnace, and Keep warm at 600°C for 1 hour, take it out after cooling to room temperature, and grind it evenly, then put the mixture into a corundum crucible, then put it into a crucible with activated carbon and cover it tightly, put it into a box furnace for sintering at 1250°C for 6 Hours, sintered and pulverized into powder, washed with deionized water, passed through a 400-mesh sieve, separated from water and powder, and dried at 180°C to obtain Gd 0.9 al 3.0 (BO 3 ) 4 :0.05Ce 3+ ,0.05Yb 3+ Down-converting luminescent material. The XRD pattern of the down-converting luminescent material is shown in figure 1 , and the excitation and near-infrared emission spectra at room temperature are shown in figure 2 .

Embodiment 2

[0025] Weigh 3.2157g of boric acid, 1.5294g of alumina, 1.8719g of ytterbium oxide and 0.0861g of cerium oxide, grind them evenly in an agate mortar, put them into a corundum crucible, put them into a high-temperature furnace, and keep them warm at 800°C for 2 hours , after cooling to room temperature, take it out and grind it evenly, and then put the mixture at 1250℃, the volume ratio is 75%N 2 :25%H 2 Sintered in an atmosphere of 10 hours, crushed into powder after sintering, washed with deionized water, passed through a 400-mesh sieve, separated from water and powder, and dried at 200 ° C to obtain Al 3.0 (BO 3 ) 4 :0.05Ce 3+ ,0.95Yb 3+ Down-converting luminescent material.

Embodiment 3

[0027]Weigh 2.7210g of boric acid, 1.0513g of gadolinium oxide, 1.4058g of gallium oxide, 0.7647g of aluminum oxide, 0.7882g of ytterbium oxide and 0.0344g of cerium oxide, grind them evenly in an agate mortar, put them into a corundum crucible, and put In the furnace, heat it at 600°C for 1 hour, take it out after cooling to room temperature and grind it evenly, and then put the mixture at 1200°C with a volume ratio of 75%N 2 :25%H 2 Sintered under the atmosphere of 6 hours, crushed into powder after sintering, washed with deionized water, passed through a 400-mesh sieve, separated from water and powder, and dried at 150°C to obtain Gd 0.58 Al 1.5 Ga 1.5 (BO 3 ) 4 :0.02Ce 3+ ,0.40Yb 3+ Down-converting luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com