Preparation method of granular catalyst suitable for catalytic combustion of VOCs

A catalytic combustion, particle-type technology, applied in combustion methods, physical/chemical process catalysts, combustion types, etc., can solve the problem of low catalytic activity, and achieve the effects of high catalytic activity, large specific surface area, and simple and effective preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

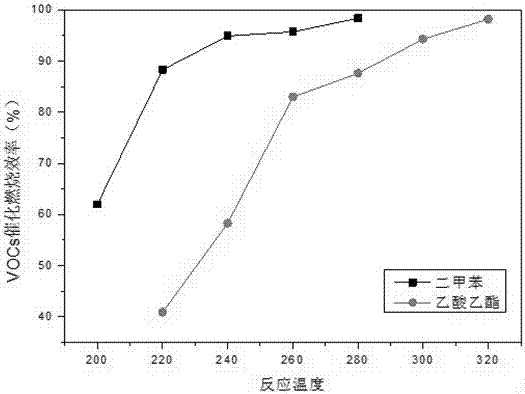

[0021] Embodiment 1: as attached figure 1 Shown, a kind of preparation method applicable to the granular catalyst of VOCs catalytic combustion is characterized in that comprising the following steps successively:

[0022] (1) Carrier pretreatment: use alumina as the skeleton carrier, where γ-Al 2 o 3 The weight ratio is 94%, the particle size is 3mm, and the specific surface area is 320m 2 / g, the bulk density is 0.68g / mL, and then soaked in deionized water for 8h,

[0023] (2) Carrier impregnation: The impregnation solution includes 18kg deionized water, 50ml chloropalladium acid and 50ml chloroplatinic acid, adjust the pH to 2.0 with dilute nitric acid solution, then perform 5min stirring operation and 2h impregnation operation in sequence;

[0024] (3) Reduction treatment: After the impregnation operation is completed, the reduction operation is carried out in a deionized aqueous solution of hydrogen peroxide, and the reduction time is 2 hours;

[0025] (4) Post-process...

Embodiment 2

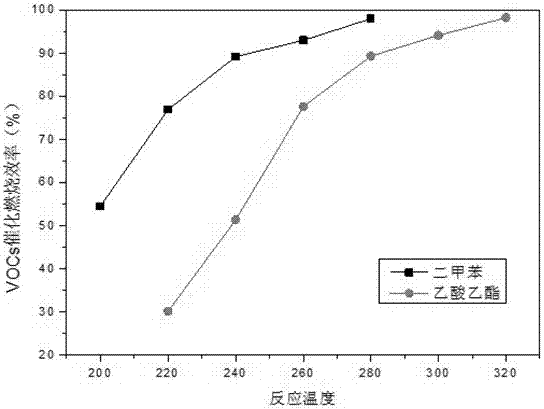

[0028] Embodiment 2: as attached figure 2 Shown, a kind of preparation method applicable to the granular catalyst of VOCs catalytic combustion is characterized in that comprising the following steps successively:

[0029] (1) Carrier pretreatment: use alumina as the skeleton carrier, where γ-Al 2 o 3 The weight ratio is 96%, the particle size is 5mm, and the specific surface area is 350m 2 / g, the bulk density is 0.68g / mL, and then soaked in deionized water for 10h,

[0030] (2) Carrier impregnation: The impregnation solution includes 18kg deionized water, 100ml chloropalladium acid and 100ml chloroplatinic acid, adjust the pH to 3.0 with dilute nitric acid solution, then perform 10min stirring operation and 2h impregnation operation in sequence;

[0031] (3) Reduction treatment: After the impregnation operation is completed, the reduction operation is carried out in a deionized aqueous solution of hydrogen peroxide, and the reduction time is 2 hours;

[0032] (4) Post-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com