Bearing and preparation technology thereof

A production process and bearing technology, applied in the field of bearings and their production processes, can solve problems such as lack of strength, hardness, numerous processes, and low hardness, and achieve the effects of reducing product weight, optimizing mechanical properties, and increasing surface rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

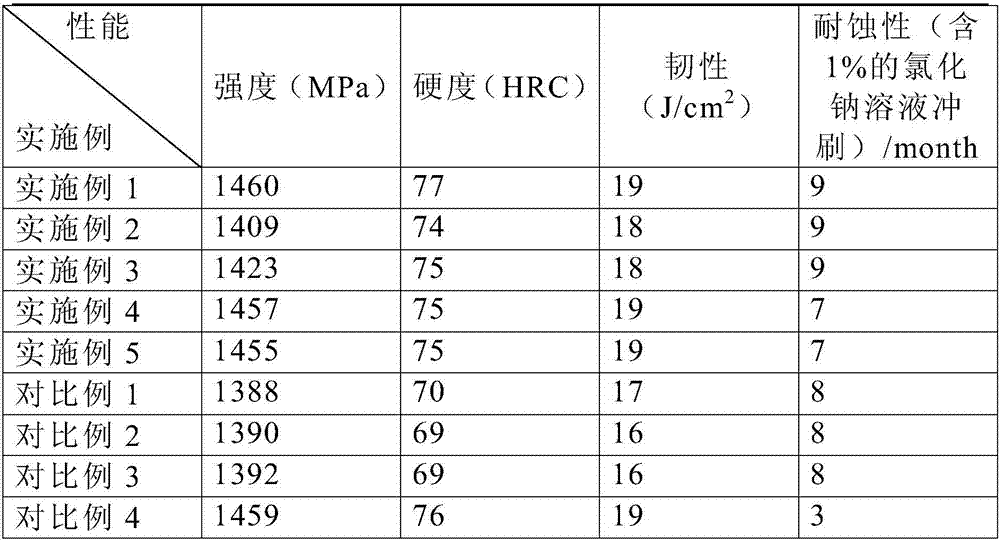

Examples

Embodiment 1

[0033] Ingredients: Weigh raw materials according to the composition and mass percentage of the above alloy steel, including Cd: 0.06%, Mn: 1%, C: 0.6%, Tl: 0.1%, Cu: 0.03%, Co: 0.05%, and the balance is Fe and impurities, wherein impurities include P<0.04%, S<0.04%, N<0.04%, O<0.03%. The raw materials are melted to form alloy liquid and poured into the mold to form bearing semi-finished products.

[0034] Heat treatment: Temper the bearing semi-finished product first, heat it to 550°C, keep it warm for 10 minutes, cool it down to room temperature naturally, and then perform annealing treatment, heat the semi-finished product to 350°C, keep it warm for 5 minutes, cool it with the furnace, and then perform the second isothermal tempering treatment , keep warm for 3 minutes, cool to room temperature with external air, and finally anneal for the second time at a lower temperature, heat to 250°C, keep warm for 3 minutes and then cool naturally to room temperature.

[0035] Blendi...

Embodiment 2

[0038] Ingredients: Weigh raw materials according to the composition and mass percentage of the above alloy steel, including Cd: 0.05%, Mn: 0.5%, C: 0.4%, Tl: 0.08%, Cu: 0.01%, Co: 0.03%, and the balance is Fe and impurities, wherein impurities include P<0.04%, S<0.04%, N<0.04%, O<0.03%. The raw materials are melted to form alloy liquid and poured into the mold to form bearing semi-finished products.

[0039] Heat treatment: Temper the bearing semi-finished product first, heat it to 400°C, keep it warm for 5 minutes, cool it down to room temperature naturally, and then perform annealing treatment, heat the semi-finished product to 300°C, keep it warm for 1 minute, cool it with the furnace, and then perform the second isothermal tempering treatment , keep warm for 1min, cool to room temperature with external air, and finally anneal for the second time at a lower temperature, heat to 200°C, keep warm for 1min and then cool naturally to room temperature.

[0040] Blending of exter...

Embodiment 3

[0043] Ingredients: Weigh raw materials according to the composition and mass percentage of the above alloy steel, including Cd: 0.07%, Mn: 1.5%, C: 0.8%, Tl: 0.12%, Cu: 0.05%, Co: 0.07%, and the balance is Fe and impurities, wherein impurities include P<0.04%, S<0.04%, N<0.04%, O<0.03%. The raw materials are melted to form alloy liquid and poured into the mold to form bearing semi-finished products.

[0044] Heat treatment: Temper the bearing semi-finished product first, heat it to 700°C, keep it warm for 15 minutes, cool it down to room temperature naturally, then perform annealing treatment, heat the semi-finished product to 400°C, keep it warm for 10 minutes, cool it with the furnace, and then perform the second isothermal tempering treatment , heat preservation for 5 minutes, external air cooling to room temperature, and finally a second annealing at a lower temperature, heating to 300 ° C, heat preservation for 5 minutes, and then naturally cooling to room temperature. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com