Preparation method of anisotropic biomedical directional solidification magnesium-zinc alloy material

A technology of directional solidification and anisotropy, which is applied in the field of anisotropic biomedical directional solidification magnesium-zinc alloy materials, can solve problems such as too fast degradation of magnesium-zinc alloys, equiaxed crystal structures that cannot meet the requirements of anisotropy, and achieve The effect of convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

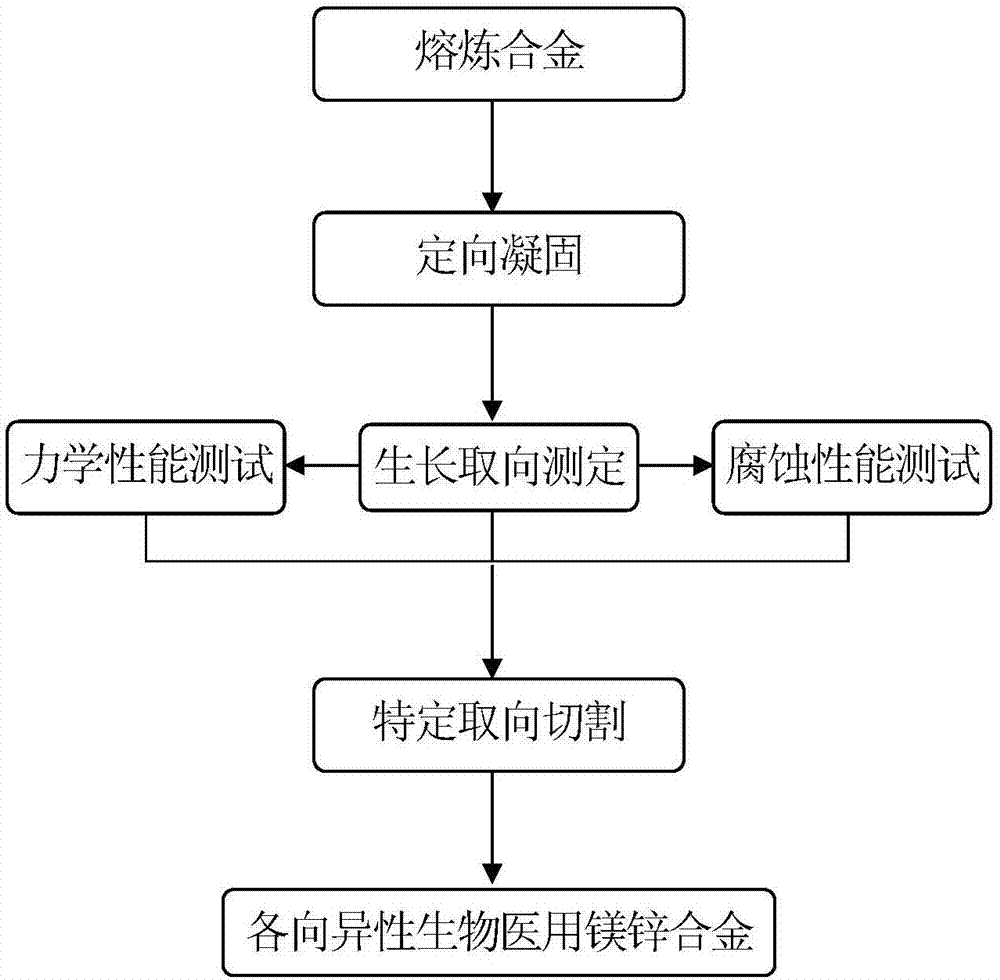

[0035] In this embodiment, the method for preparing anisotropic biomedical directionally solidified magnesium-zinc alloy material has the following specific steps:

[0036] (1) Put 192 grams of Mg (purity 99.99wt%) and 8 grams of Zn (purity 99.99wt%) in a low-carbon steel crucible, smelt Mg-4Zn magnesium alloy at 730℃, keep the temperature for 30 minutes and then cool to 680℃ Cast, get Bar

[0037] (2) Put The rod is placed in a high-purity corundum tube for directional solidification preparation, the directional solidification heating temperature is 800°C, the temperature gradient is 10°C / mm, and the drawing speed is 120μm / s;

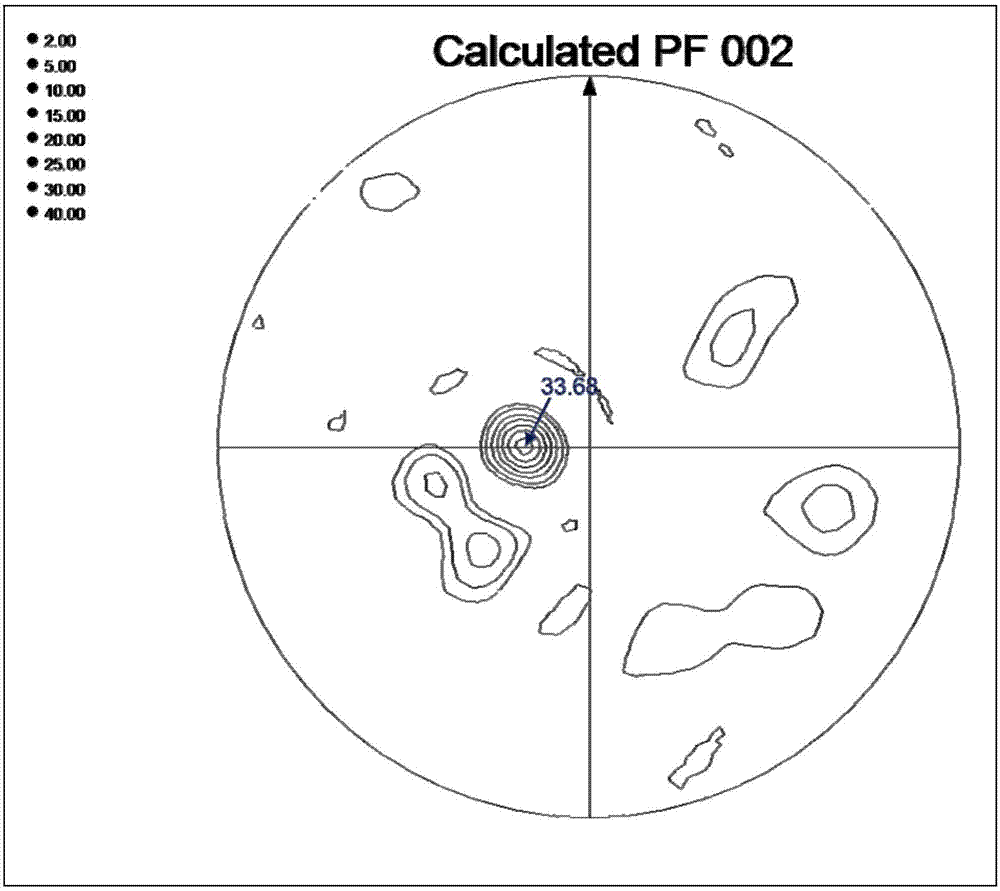

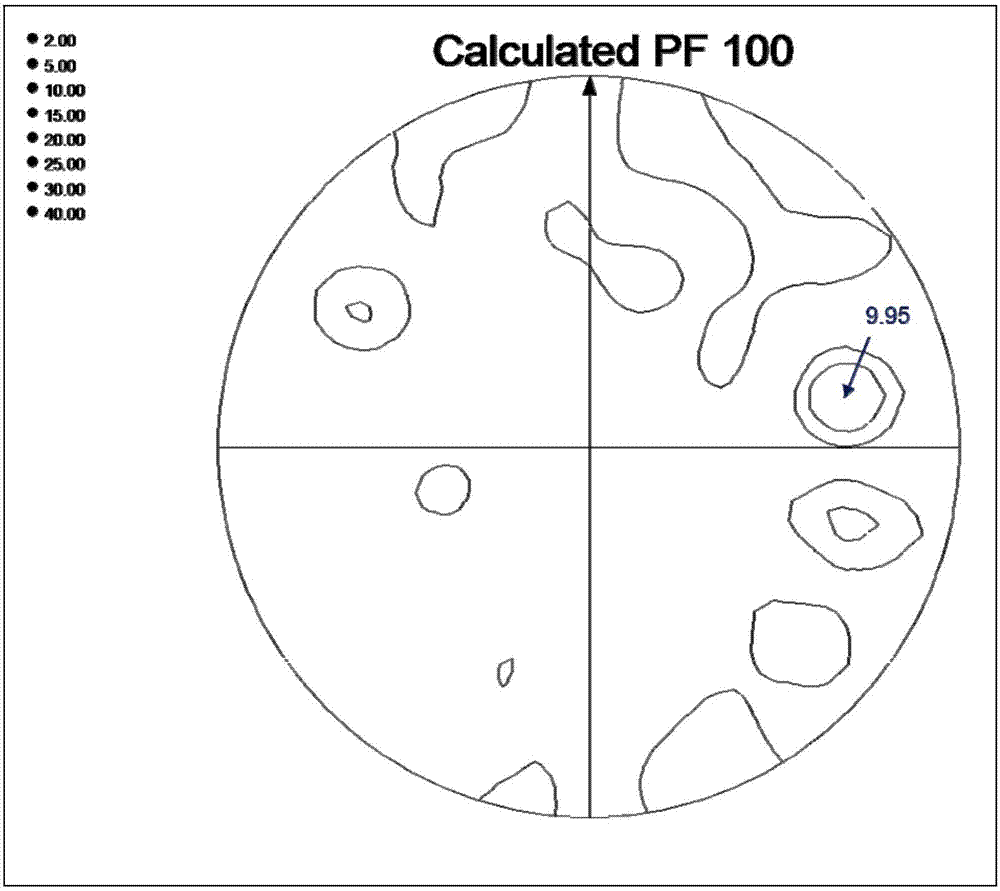

[0038] (3) Using XRD, EBSD and TEM techniques to determine the growth orientation of directionally solidified Mg-4Zn alloy bars, and respectively determine the corrosion performance of different orientation crystal faces in 0.9% NaCl solution, and then determine the corrosion resistance of the crystal faces in Hank's simulation Degradation performance in b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com