Nano-silver anti-microbial regenerated silk fibroin material and preparation method thereof

An antibacterial technology for regenerated silk fibroin and nano-silver, which is applied in the direction of single-component silk fibroin rayon, rayon manufacturing, wet spinning, etc. Achieve the effect of preventing agglomeration, durable antibacterial, and easy to run off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

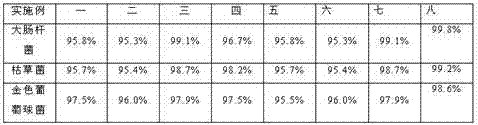

Examples

Embodiment 1

[0032] (1) Dissolve the conventional regenerated silk fibroin film in 88% formic acid aqueous solution with a mass fraction of 10% silk fibroin;

[0033] (2) Then add silver nitrate to the formic acid solution, the mass fraction of silver nitrate is 0.001%, and dissolve with magnetic stirring for 30 minutes in the dark, at a temperature of 15°C;

[0034] (3) Pour the solution obtained in step (2) into a polyethylene dish, and dry it naturally to form a film;

[0035] (4) Soak the film obtained in step (3) in an ethanol solution with a mass fraction of 75% for 30 minutes, then fully wash it with deionized water, and dry it naturally to obtain a nano-silver antibacterial regenerated silk fibroin film; carry out X- The ray diffraction test found that a large amount of nano-silver exists in the product, and the X-ray diffraction test pattern showed the characteristic diffraction peaks of nano-silver at 38°, 44°, 64° and 77°. The transmission electron microscope test also observed ...

Embodiment 2

[0037] (1) Dissolve the conventional regenerated silk fibroin film in 98% formic acid aqueous solution with a mass fraction of 15% silk fibroin;

[0038] (2) Then add silver sulfate to the formic acid solution, the mass fraction of silver sulfate is 0.005%, and dissolve with magnetic stirring for 1 hour in the dark, at a temperature of 25°C;

[0039] (3) wet spinning the solution obtained in step (2), using ethanol as a coagulation bath, and winding to obtain regenerated silk fibroin filament fibers;

[0040] (4) Stretch the filament fiber obtained in step (3) in a wet state, the stretching ratio is 2 times, and obtain nano-silver antibacterial regenerated silk fibroin filament fiber with excellent mechanical properties after vacuum drying; perform X-ray diffraction During the test, it was found that a large amount of nano-silver exists inside the fiber. The X-ray diffraction test pattern shows the characteristic diffraction peaks of nano-silver at 38°, 44°, 64° and 77°. The t...

Embodiment 3

[0042](1) Dissolve the conventional regenerated silk fibroin film in 90% formic acid aqueous solution with a mass fraction of 12% silk fibroin;

[0043] (2) Then add silver fluoride to the formic acid solution, the mass fraction of silver fluoride is 0.002%, and dissolve with magnetic stirring for 2 hours in the dark, at a temperature of 35°C;

[0044] (3) Electrospinning the solution obtained in step (2) with a spinning voltage of 12kV, a spinning distance of 12cm, and a flow rate of 0.5ml / h to obtain electrospun fibroin nanofibers with a fiber diameter of 100-500nm between;

[0045] (4) Soak the nanofibers obtained in step (3) in a methanol solution with a mass fraction of 75% for 30 minutes, then fully wash with deionized water, and dry naturally to obtain a nano-silver antibacterial silk fibroin nanofiber membrane; X-ray diffraction test found that a large amount of nano-silver exists inside the product, and the X-ray diffraction test pattern showed characteristic diffrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com