Photochromic microspheres and preparation method thereof

A photochromic and photochromic dye technology, applied in the field of photochromic polymer microspheres, can solve the problems of poor thermal stability and mechanical properties, unfavorable large-scale production, complex double-layer coating process, etc. Good stability, excellent mechanical properties, and the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 2g polylactic acid, 0.2g spirooxazine organic photochromic dye, 0.5g dibutyl hydroxytoluene, 0.3g 2-hydroxyl-4-n-octyloxybenzophenone and 0.3g 1-hydroxyl-2-naphthoyl phenyl Dissolve in 10g of dichloromethane solvent, then add to 50g of 2wt% polyvinyl alcohol aqueous solution, add 2g of isobutanol at the same time, emulsify at a high speed of 3000rpm for 10min, after making a stable oil-in-water emulsion, the emulsion The particle size is 5-35 microns by optical microscope observation. Transfer the above-mentioned oil-in-water emulsion to a three-necked flask, heat up to 50°C while stirring and keep it warm for 120 minutes. After that, a polymer containing photochromic compound molecules uniformly dispersed can be obtained. Lactic acid microsphere suspension. The suspension was suction filtered and washed to obtain a filter cake. After the filter cake is vacuum-dried, the photochromic microsphere dry powder can be obtained.

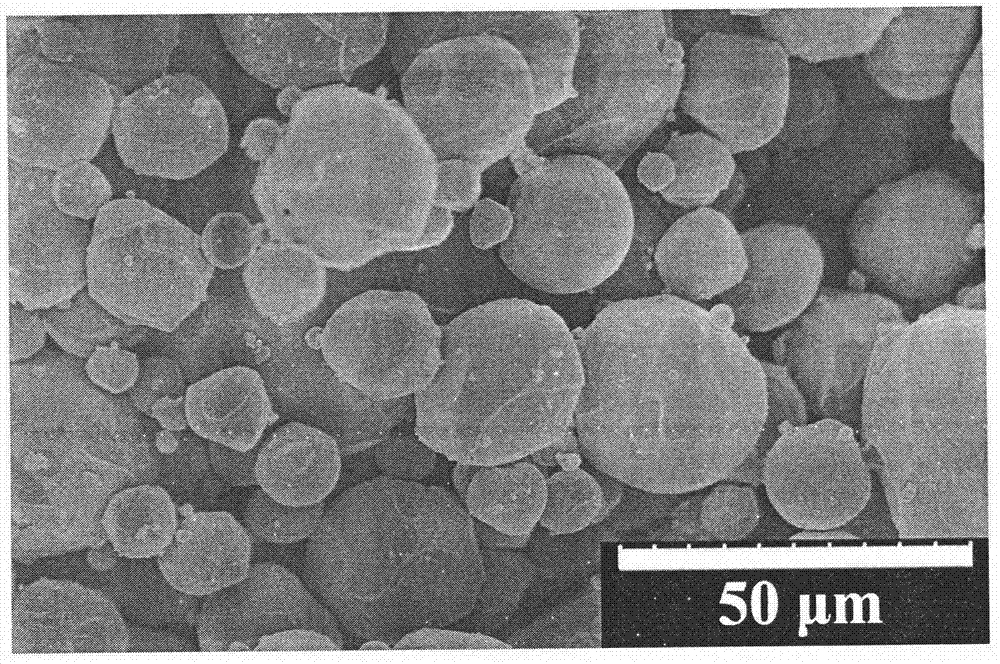

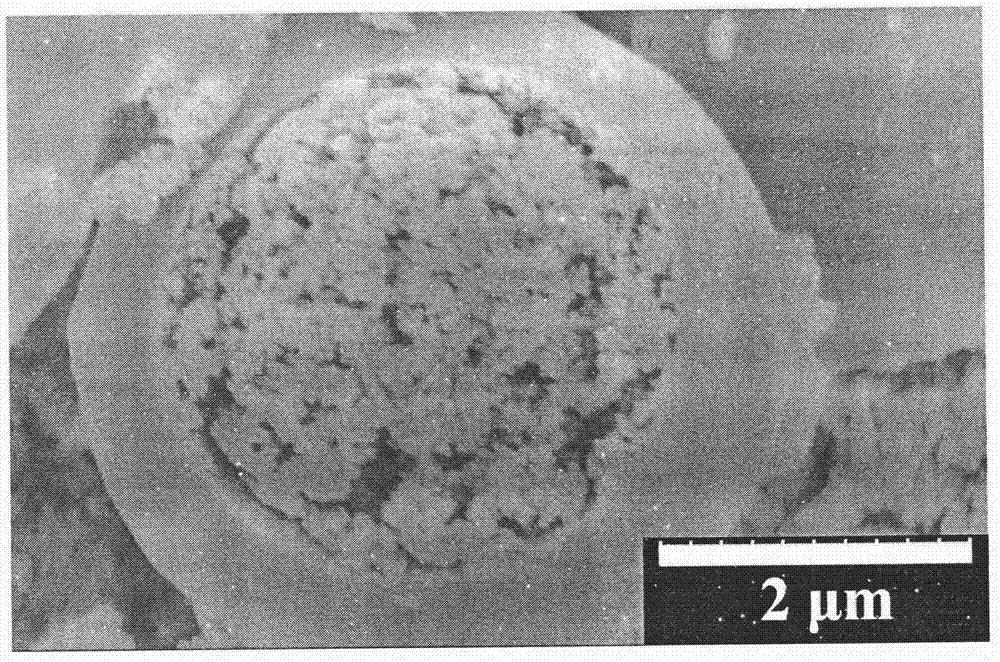

[0025] The morphology of the microspheres p...

Embodiment 2

[0027] Swell 10g cellulose acetate with 100g chloroform, 10g 1-hydroxyethyl-3,3-dimethyl-nitroindoline spiropyran optical variable dye, 1g thiodipropionate dilaurate, 0.5g4 - Benzoyloxy-2,2,6,6-tetramethylpiperidine and 0.3 g of p-benzylbiphenyl were dissolved for 24 hours, then stirred and dissolved to obtain a homogeneous oil phase solution. Add it to 800g concentration of 4wt% alkylphenol polyoxyethylene ether formaldehyde condensate sulfate solution, emulsify at a high speed at 30000rpm for 30min, after making a stable oil-in-water emulsion, the emulsion droplet size is observed by optical microscope Measured from 0.1 to 2 microns. Transfer the above stable oil-in-water emulsion to a 2-liter three-neck flask, raise the temperature to 60°C while stirring and keep it warm for 120 minutes, then the cellulose ester microsphere suspension containing photochromic compound molecules uniformly dispersed can be prepared. The suspension was suction filtered and washed to obtain a f...

Embodiment 3

[0029] With 20kg ethyl acetate, 1kg thermoplastic polyurethane, 1kg spiropyran organic photochromic dye, 60g tert-butyl hydroquinone, 50g resorcinol monobenzoate and 30g dibenzyl oxalate are dissolved to obtain a solution, Then add it to 100kg of sodium lauryl sulfate solution, which contains 1kg of sodium lauryl sulfate, 1kg of n-octanol, 2kg of Tween 60, and emulsify at a high speed of 9000rpm for 60min to obtain a stable oil-in-water type After the emulsion, the particle size of the emulsion droplets is observed and measured by an optical microscope to be 2 to 15 microns, and the above-mentioned oil-in-water emulsion is directly spray-dried, and the spray-drying conditions are that the inlet temperature is set to 150°C, and the outlet temperature is set to 80°C, namely The dry powder of photochromic microspheres can be obtained directly. The particle size of the microspheres measured by an electron microscope is regular and spherical, and the particle size distribution is w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com