Inorganic metallic oxide thin-film with composite crystal form and manufacturing method thereof

A technology of oxide thin films and inorganic metals, which is applied in metal material coating technology, semiconductor/solid-state device manufacturing, transistors, etc., can solve the problems of poor uniformity of small-sized devices, achieve carrier mobility improvement, and manufacture The effect of simple process, excellent and uniform electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In order to solve the problem of low carrier mobility caused by the disordered arrangement of atoms in amorphous inorganic metal oxide films, and the poor spatial uniformity of electrical properties of low-temperature polysilicon films and polycrystalline inorganic metal oxide films, This embodiment proposes an indium tin zinc oxide thin film with a composite crystal form.

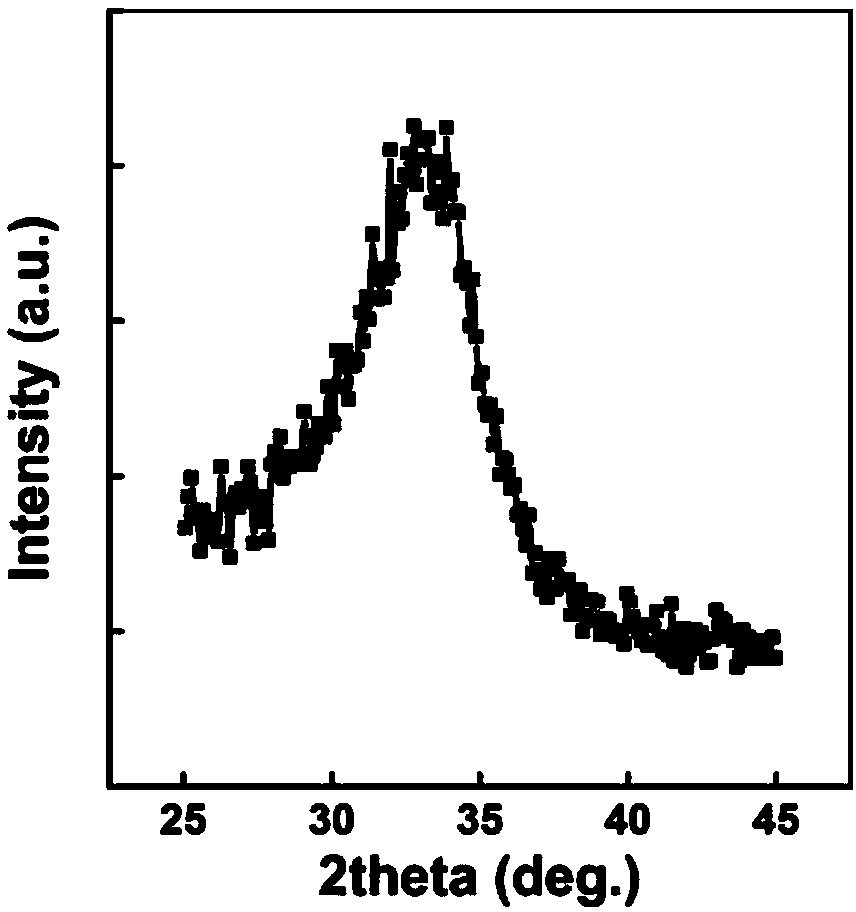

[0048] The structure of the indium tin zinc oxide film with composite crystal form includes crystal grains and an amorphous structure, the crystal grains are surrounded by an amorphous frame, and the atomic order of the indium tin zinc oxide film is between Between amorphous and polycrystalline materials, the grain size is 0.5 nm to 10 nm. Similarly, the composition of the film can also be indium tin oxide, indium gallium oxide, indium zinc oxide, tin gallium oxide, tin zinc oxide, gallium zinc oxide, indium tin zinc oxide, indium gallium zinc oxide , indium gallium tin zinc oxide, fluorine doped t...

Embodiment 2

[0050] refer to figure 1 with figure 2 , the manufacturing method of the indium tin zinc oxide thin film of composite crystal form in the present embodiment 1, comprises the following steps:

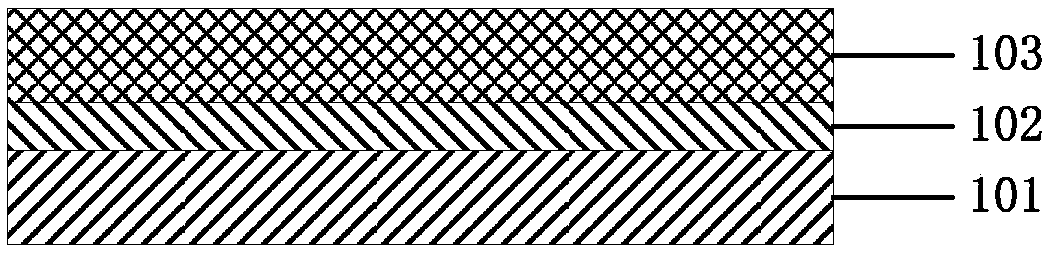

[0051] A1, use plasma-enhanced chemical vapor deposition to deposit a layer of silicon dioxide on the glass substrate 101 as the buffer layer 102, such as figure 1 shown.

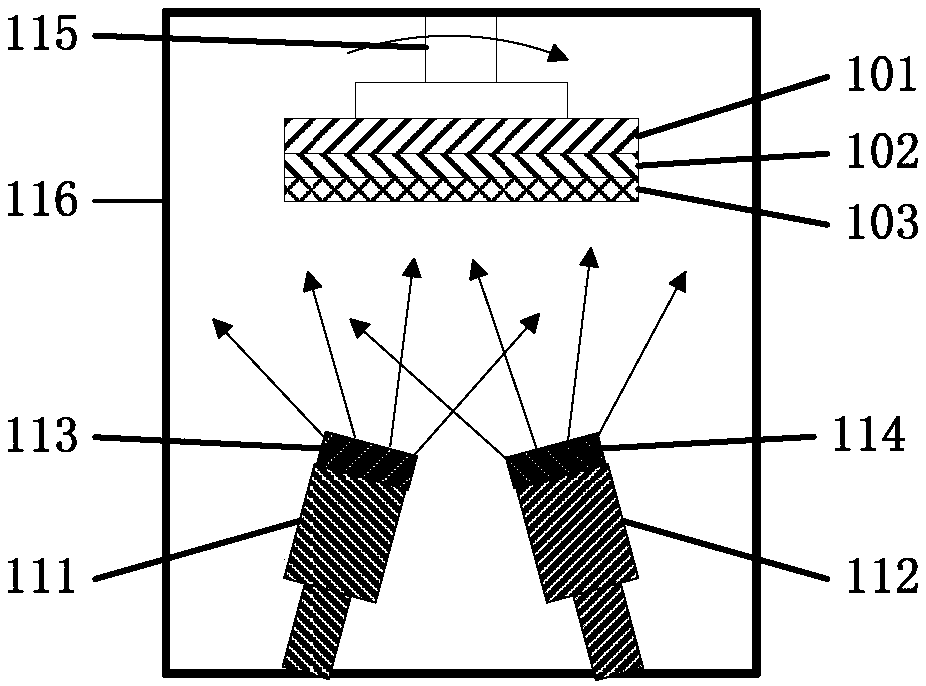

[0052] A2. On the buffer layer 102, magnetron sputtering polycrystalline indium tin oxide target material 113 and polycrystalline zinc oxide target material 114 at the same time, to deposit the indium tin zinc oxide thin film 103 of composite crystal form, such as figure 2 shown. The thickness of the indium tin zinc oxide thin film 103 is 50 nanometers.

[0053] A3. Using a tube furnace, annealing is performed on the composite crystal form indium tin zinc oxide thin film, the annealing temperature is 300° C., and the annealing time is 1 hour.

[0054] Such as figure 2 As shown, the composition of the polycrys...

Embodiment 3

[0059] The indium tin zinc oxide thin film manufactured in embodiment 2 is applied in an indium tin zinc oxide thin film transistor, and the indium tin zinc oxide thin film having a composite crystal form is used as an active layer of the transistor. And carry out transfer characteristic test to the transistor that makes,

[0060] from Figure 5 with Image 6 It can be seen from the figure that the indium tin zinc oxide thin film transistors (including long-channel and short-channel thin film transistors) manufactured in this embodiment have excellent electrical properties, and the short-channel thin film transistors have no Obvious short channel effect. pass Figure 5 with Image 6 It can be concluded that the field effect carrier mobility of the indium tin zinc oxide thin film transistor with the composite crystal form is greater than 20 cm 2 / Vs, the subthreshold swing is lower than 0.15V / decade, and the transistor with the same structure using the amorphous indium tin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com