Crystal grain size averaging method based on polycrystalline material extraction by effective ultrasonic backscatter signal

An ultrasonic backscattering, average size technology, applied in the analysis of materials, the use of sonic/ultrasonic/infrasonic waves to analyze solids, instruments, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in more detail with reference to the embodiments and the accompanying drawings. The adopted examples are used to illustrate the present invention, but not to limit the scope of application of the present invention.

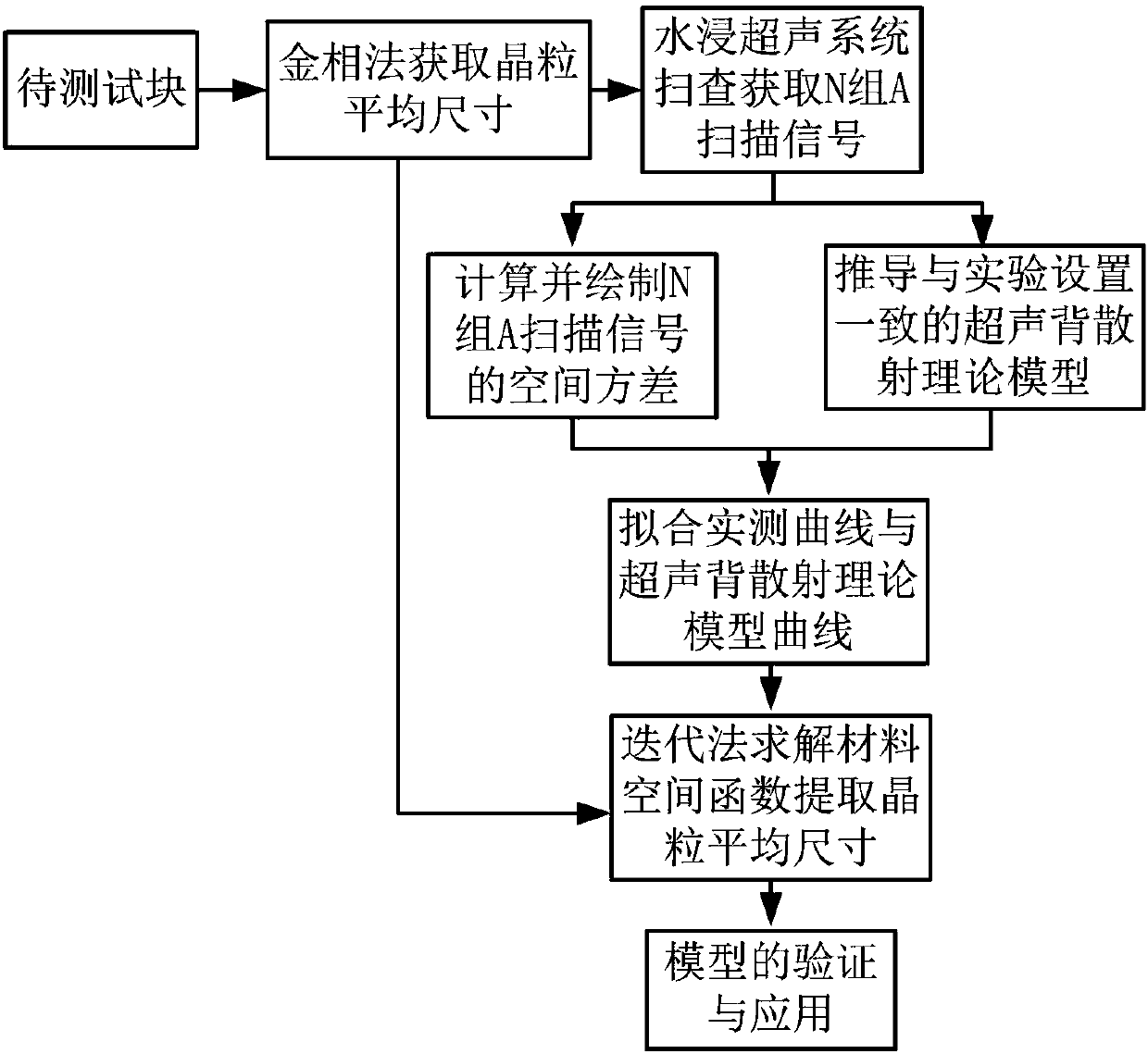

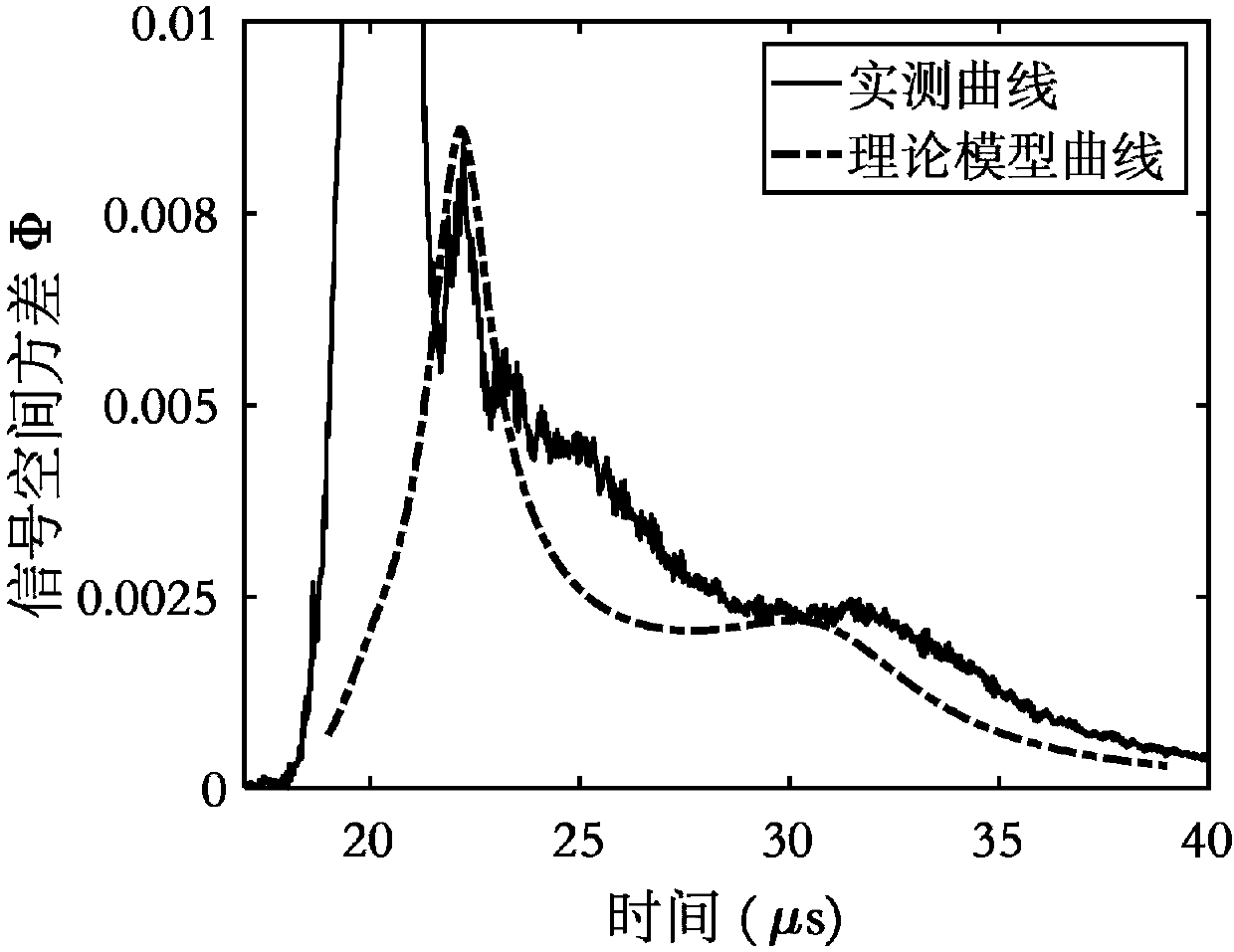

[0029] This specific embodiment takes stainless steel as an example, figure 1 It is a flowchart of a method for extracting the average grain size of polycrystalline materials based on effective ultrasonic backscattering signals of the present invention. In order to obtain the average grain size of the test block, the specific detection steps are as follows:

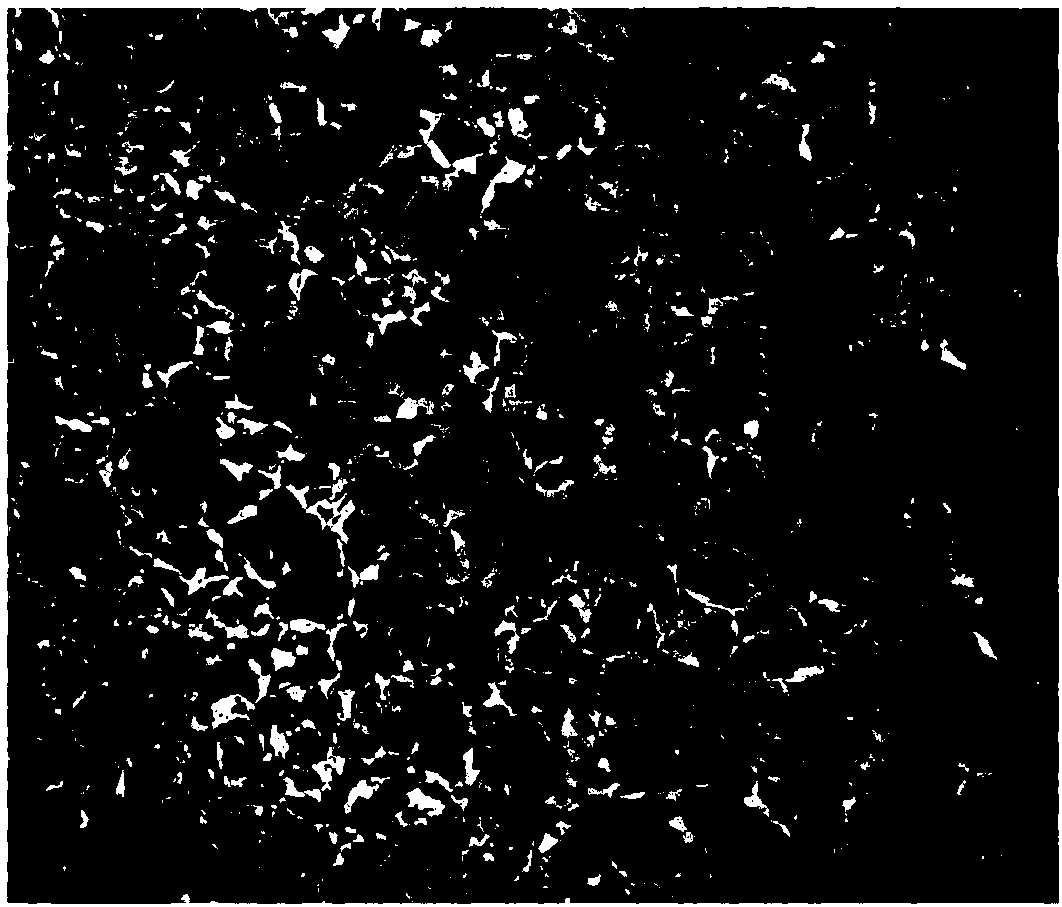

[0030] Step 1. Cut a cube of 15mm×15mm×15mm from the stainless steel test block to be tested as a metallographic sample, and then go through the steps of rough grinding, fine grinding, polishing, corrosion and observation, and finally according to GB / T6394-2002 metal average grain Grain Size Determination of Average Grain Size of Stainless Steel Reference Blocks A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com