Stainless steel dust treatment process

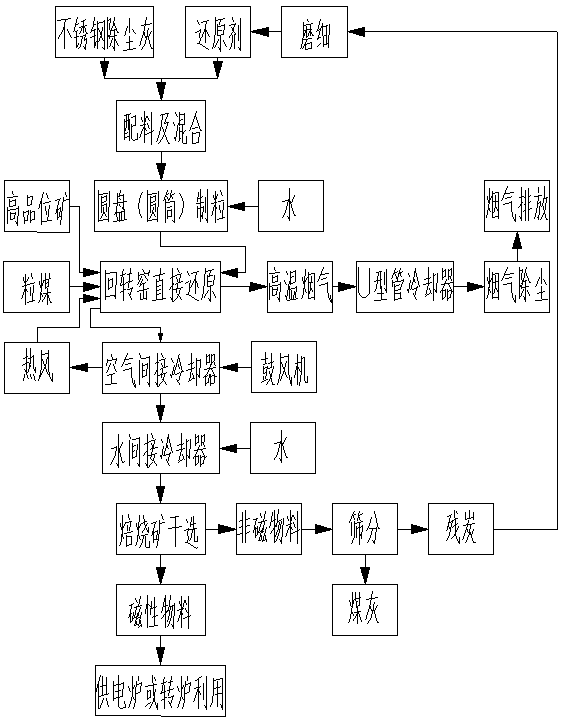

A treatment process, stainless steel technology, applied in the field of stainless steel dust removal rotary kiln direct reduction treatment process, can solve the problems of low metallization rate of products, difficult sewage treatment, high reduction temperature, etc., to meet environmental protection requirements, shorten reduction time, reduce Effect of reduction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A stainless steel dedusting ash treatment process, the specific process is as follows:

[0034] 1. Selection of materials

[0035] Stainless steel dust: iron grade is 33%, SiO 2 Mass content 7%, Cr 2 o 3 The mass content is 10%, and the Ni mass content is 1%.

[0036] High volatile granular coal: 44% fixed carbon mass content, 9% ash mass content, 49% volatile matter mass content, and 20mm particle size.

[0037] High-grade hematite: the iron grade is 45%, and the particle size is 1mm.

[0038] 2. Material granulation

[0039] Stainless steel dedusting ash and reduced coal are batched and mixed according to the mass ratio of 100:10, and the disc granulator is used to make granular materials with a water content of 12% and a particle size of 3mm. The reduced coal is ground by the residual carbon returned from the rotary kiln. Powder as fine as 200 mesh accounts for more than 40%

[0040] 3. Reduction, pulverization and pelletization of granular materials

[0041]...

Embodiment 2

[0051] A stainless steel dedusting ash treatment process, the specific process is as follows:

[0052] 1. Selection of materials

[0053] Stainless steel dust: iron grade is 38%, SiO 2 Mass content 5%, Cr 2 o 3 The mass content is 17%, and the Ni mass content is 2%.

[0054] High volatile granular coal: fixed carbon mass content is 46%, ash content is 7%, volatile matter content is 47%, particle size is 5mm.

[0055] High-grade hematite: the iron grade is 47%, and the particle size is 10mm.

[0056] 2. Material granulation

[0057] Stainless steel dedusting ash and reduced coal are batched and mixed according to the mass ratio of 100:20, and the cylinder granulator is used to make granular materials with a water content of 10% and a particle size of 5mm. The reduced coal is returned by the rotary kiln. Grinding to 200 mesh accounts for more than 40% of the powder.

[0058] 3. Reduction, pulverization and pelletization of granular materials

[0059] The granular materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com