Traditional Chinese medicine dreg composite material panel capable of slowly releasing traditional Chinese medicine flavor and preparation method of panel

A technology of traditional Chinese medicine dregs and composite materials, which is applied to chemical instruments and methods, flat products, and other household appliances, etc., can solve the problems of resource waste, achieve the effects of less labor, low production costs, and reduced plastic volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

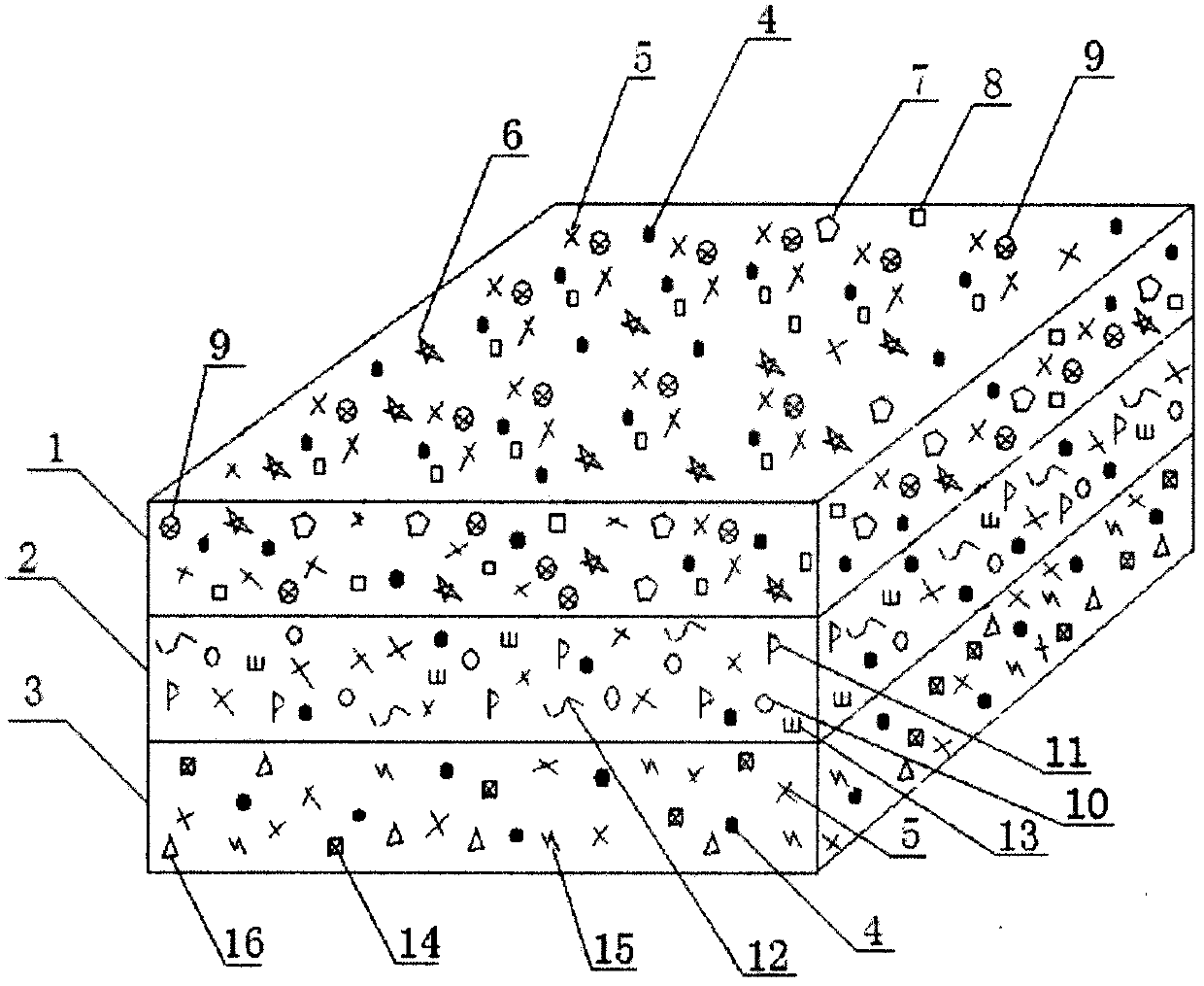

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: A kind of preparation method of the traditional Chinese medicine dregs composite material plate of sustained-release traditional Chinese medicine fragrance, its preparation process is:

[0040] (1) Polyvinyl chloride plastic particles, traditional Chinese medicine dregs (80 mesh), foaming agent (mass ratio 1:1), antioxidant (2,6-di-tert-butyl p-cresol), chlorinated polyvinyl chloride Ethylene (chlorine content is 25%) is mechanically mixed according to the mass ratio of 100:35:0.6:1:6, and then extruded and granulated to obtain foamed composite material particles. The extrusion temperature is 180 ° C; the foamed composite material particles, After the talcum powder is mechanically mixed according to the mass ratio of 100:25, it is calendered into a porous anti-aging surface layer by using a double-roller rubber mixer. The calendering temperature is 175 ° C, and the thickness of the porous anti-aging surface layer is 0.7 mm;

[0041] (2) Polylactic acid, po...

Embodiment 2

[0045] Embodiment 2: A kind of preparation method of the traditional Chinese medicine dregs composite material plate of sustained-release traditional Chinese medicine fragrance, its preparation process is:

[0046] (1) Polyethylene plastic particles, traditional Chinese medicine dregs (40 mesh), foaming agent (mass ratio 0.8:1), antioxidant (2,6-di-tert-butyl-p-cresol), chlorinated polyethylene (the chlorine content is 15%) according to the mass ratio of 100:30:0.4:0.8:4 mechanically mixed uniformly and then extruded and granulated to obtain foamed composite material particles at an extrusion temperature of 170°C; the foamed composite material particles, talc After the powder is mechanically mixed according to the mass ratio of 100:20, it is calendered into a porous anti-aging surface layer by using a double-roller rubber mixer. The calendering temperature is 165 ° C, and the thickness of the porous anti-aging surface layer is 0.4 mm;

[0047] (2) Polylactic acid, polyethylene...

Embodiment 3

[0051] Embodiment 3: A kind of preparation method of the traditional Chinese medicine dregs composite material plate of slow-release traditional Chinese medicine fragrance, its preparation process is:

[0052] (1) Polypropylene plastic particles, traditional Chinese medicine dregs (120 mesh), foaming agent (mass ratio 1.2:1), antioxidant (4,4'-methylene bis(2,6-di-tert-butylphenol )), chlorinated polyethylene (chlorine content is 35%) according to mass ratio 100: 40: 0.8: 1.2: 8 mechanically mixed and extruded pelletizing, obtain foamed composite material particles, extrusion temperature 190 ℃; After foaming composite material particles and talcum powder are mechanically mixed at a mass ratio of 100:30, they are calendered into a porous anti-aging surface layer by using a double-roller rubber mixer. The calendering temperature is 185°C, and the thickness of the porous anti-aging surface layer is 1mm. ;

[0053] (2) Polylactic acid, polypropylene plastic particles, fragrance (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com