Horizontal baking oven for peanut oil press

The technology of an oil press and a baking furnace, applied in the field of peanut oil pressing equipment, can solve the problems of the scorched metal smell, affect the production efficiency and progress, affect the heat conduction effect, etc. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

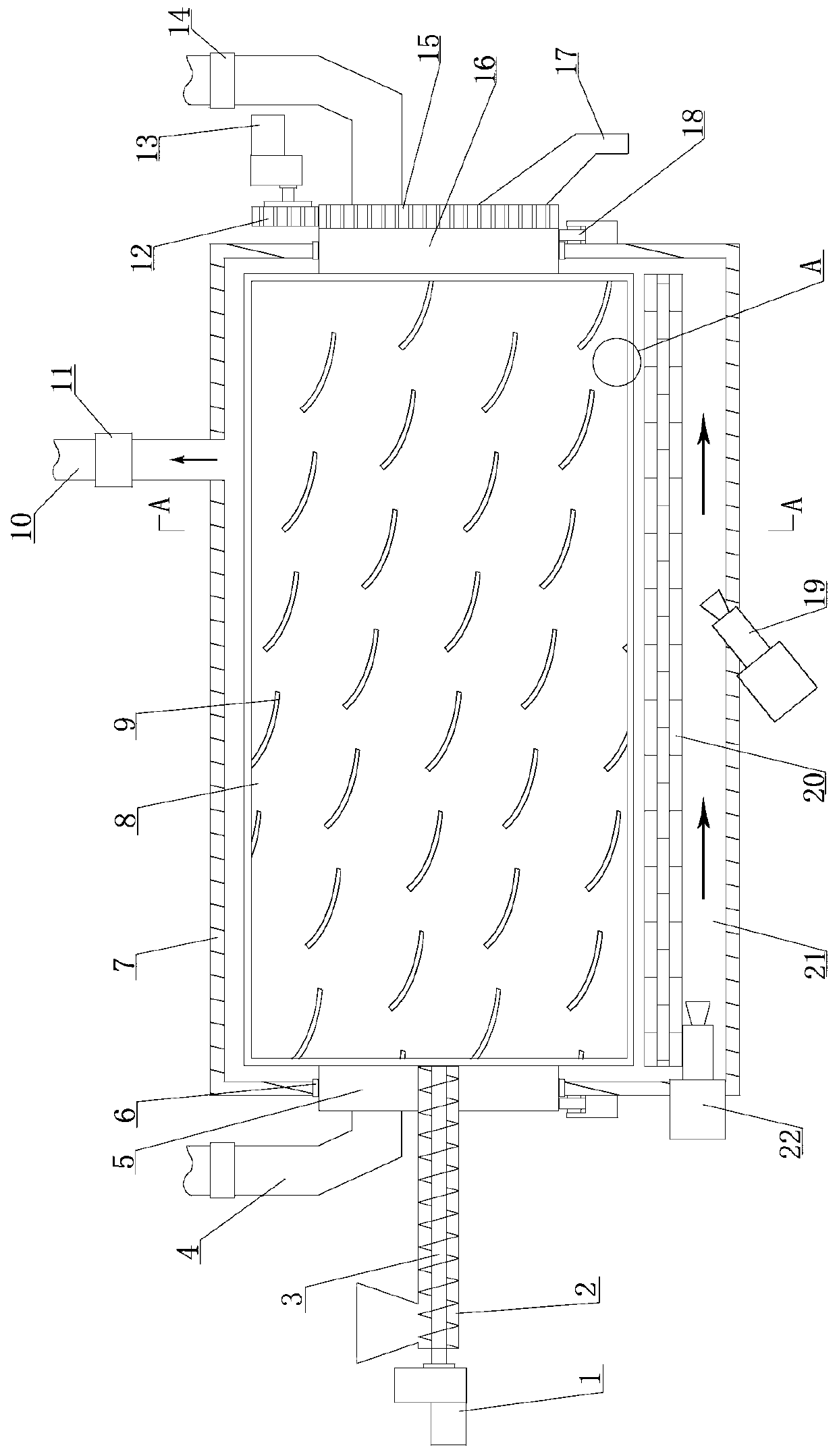

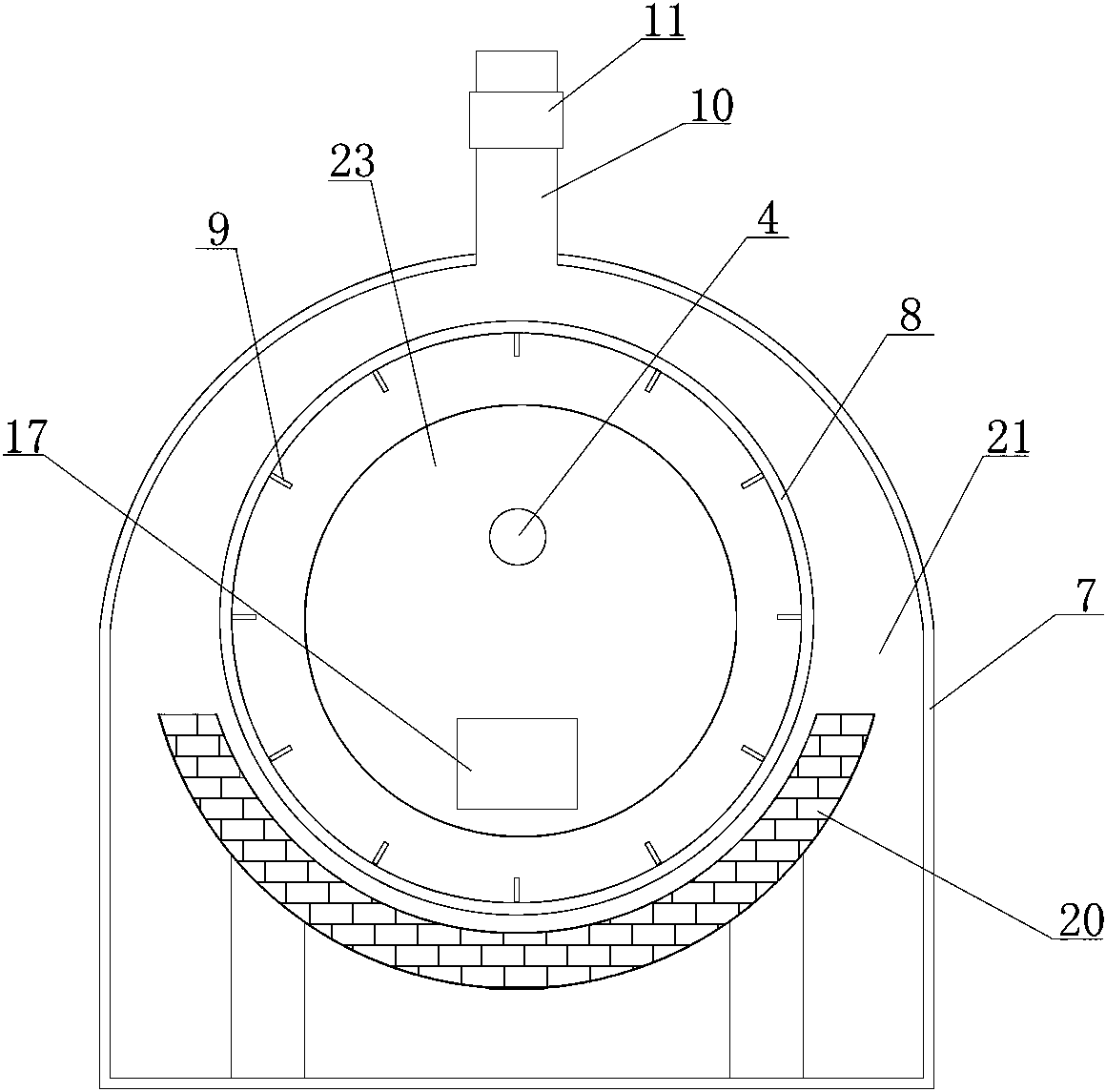

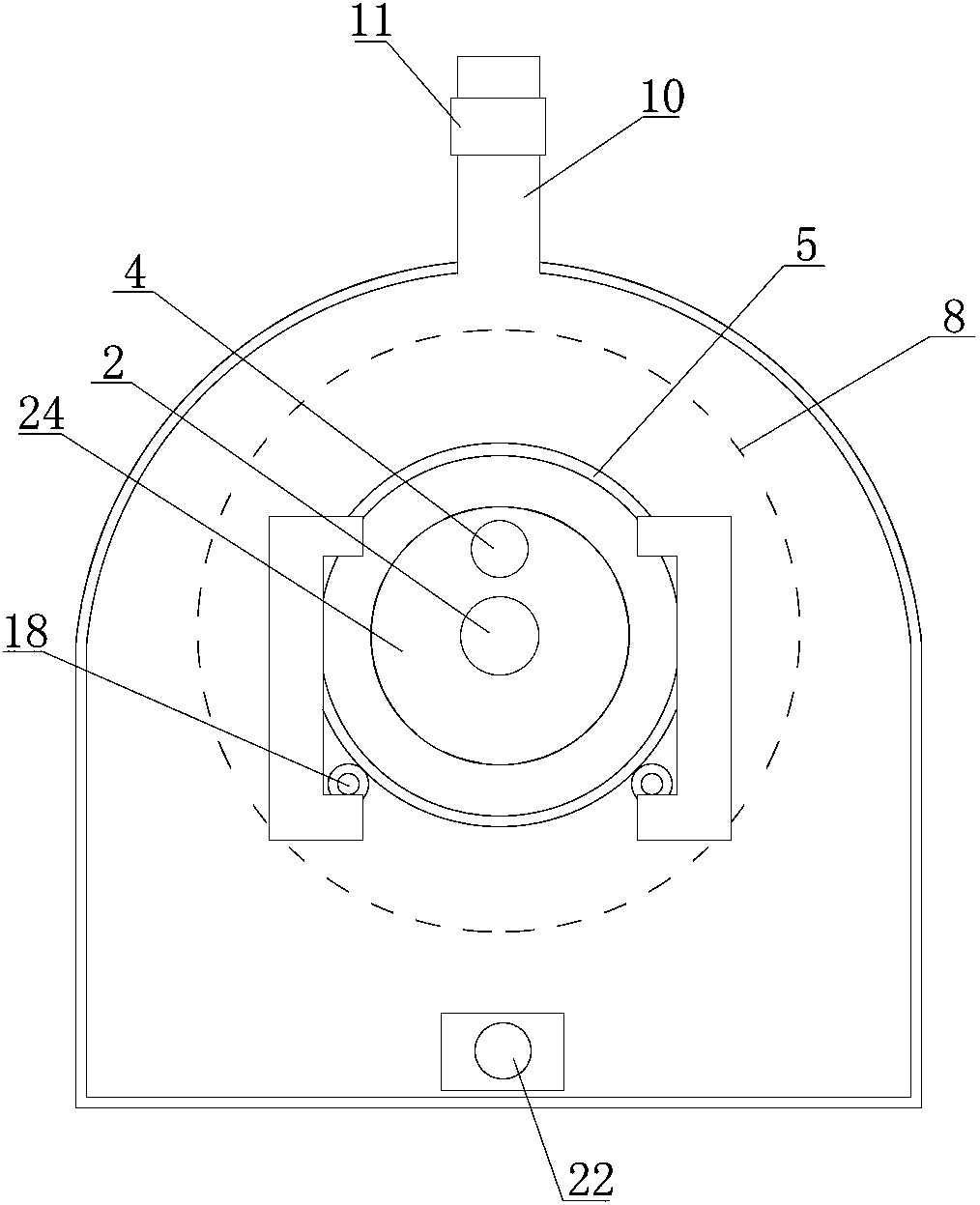

[0036] refer to Figure 1 to Figure 4 According to the present invention, it includes a heat preservation shell 7 and a baking drum 8 arranged horizontally; the baking drum 8 is arranged inside the heat preservation shell 7; 25; the front sealing rotary ring 5 and the rear sealing rotary ring 16 fixedly provided at the front and rear ends of the baking drum 8 are respectively sealed and rotatably connected to the front and rear ends of the heat preservation shell 7 through the sealing slip ring 6; The housing 7 is provided with a transmission motor 13 with a reducer; the transmission motor 13 is connected to the toothed disc 15 on the rear sealing swivel 16 through a gear 12 and is meshed with each other;

[0037] A combustion chamber 21 is left between the heat insulating shell 7 and the baking drum 8; the top of the combustion chamber 21 is provided with a smoke exhaust pipe 10 communicating with it and having an induced draft fan I11, and the bottom of the combustion chambe...

Embodiment 2

[0047] The ceramic layer and the ceramic scraper plate of the present invention have an integrated structure, which is specifically prepared according to the following process:

[0048] Step 1) Take each raw material by weight for later use, including 80 parts of fly ash, 50 parts of potassium feldspar, 30 parts of quartz sand, 22 parts of hydroxyapatite, 15 parts of mica powder, 10 parts of diatomaceous earth, silicon carbide 8 parts, 6 parts of polysulfone resin, 6 parts of polyimide, 80 parts of water;

[0049] Step 2) Mix potassium feldspar, quartz sand, hydroxyapatite, diatomaceous earth and silicon carbide, then dry at 0°C for 24 hours, then cool to room temperature naturally in a dry place, and then put it into a ball mill to grind until 100 mesh powder;

[0050] Step 3) Put fly ash, mica powder, polysulfone resin, polyimide and the powder obtained in step 2) into the mixer in turn, add water, stir at 200rpm for 90min, and then place it in the mold for molding with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com