Method for preparing high-boiling aromatics used as heat carrier oil from heavy aromatics

A technology for high-boiling aromatics and heavy aromatics, applied in the treatment of hydrocarbon oil, hydrocarbon oil treatment products, petroleum industry, etc., can solve the problems of difficult decomposition and coking, high cost of reaction raw materials, etc., to expand utilization channels, improve production technology, and source wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

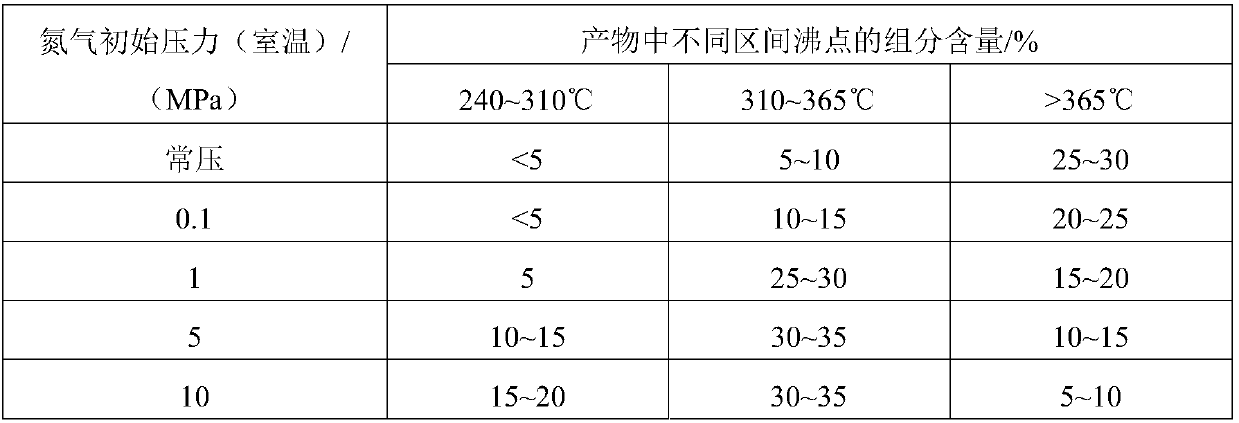

[0030] The effect of nitrogen initial pressure on the alkylation reaction of single-ring aromatic components of heavy aromatics separated by rectification and styrene, the results are shown in Table 1. The reaction is carried out in a batch reactor, and the feeding method, reaction temperature and time are the same as the description of the above batch reactor process, and the catalyst is phosphomolybdic acid.

[0031] Table 1. Results of the initial pressure of nitrogen on the single-ring aromatic components of heavy aromatics separated by rectification and the alkylation reaction of styrene

[0032]

[0033] From the above results, it can be seen that with the change of the initial nitrogen pressure, the boiling point composition of the product oil changes significantly. With increasing nitrogen pressure, the content of components with boiling points at 240-310°C and 310-365°C tended to increase, while the content of components with boiling points >365°C gradually decreas...

Embodiment 2

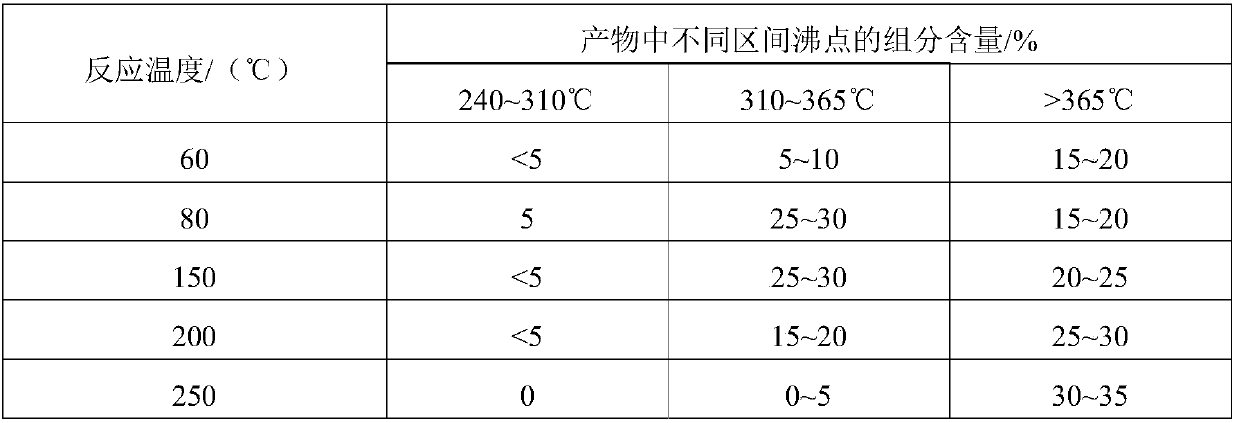

[0035] The effect of reaction temperature on the alkylation reaction of single-ring aromatic components of heavy aromatics separated by rectification and styrene, the results are shown in Table 2. The reaction is carried out in a batch reactor, and the feeding method, reaction pressure and time are the same as the description of the above batch reactor process, and the catalyst is phosphomolybdic acid.

[0036] Table 2. Effect of reaction temperature on the results of the alkylation reaction of single-ring aromatic components of heavy aromatics by rectification and styrene

[0037]

[0038] From the above results, it can be seen that with the change of reaction temperature, the boiling point composition of product oil changes significantly. In the process of increasing the reaction temperature, the content of components with boiling points at 240-310°C and 310-365°C gradually decreased, while the content of components with boiling points >365°C decreased gradually. During ...

Embodiment 3

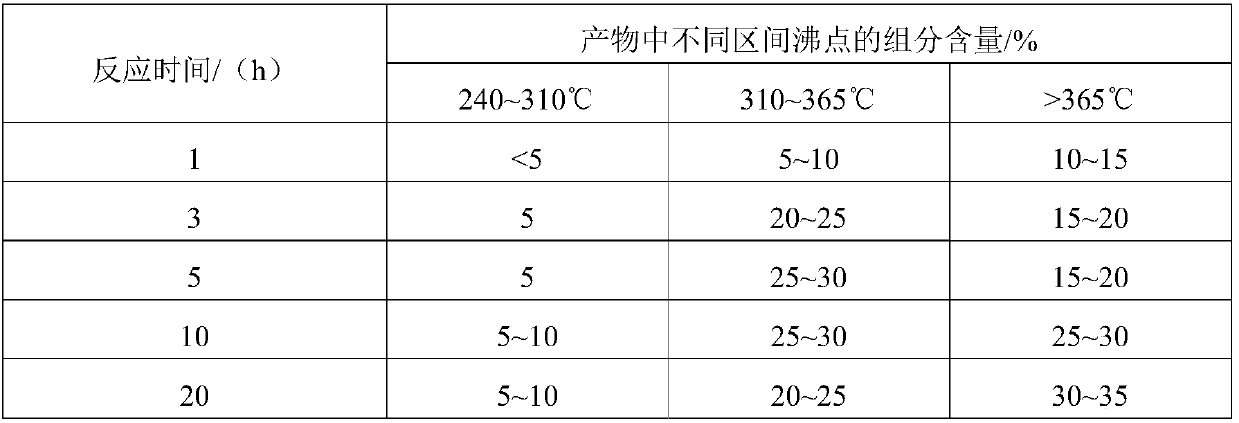

[0040] The effect of reaction time on the alkylation reaction of single-ring aromatic components of heavy aromatics separated by rectification with styrene, the results are shown in Table 3. Reaction is carried out in batch reactor, and feeding mode and reaction pressure and temperature are described with above-mentioned batch reactor technology, and catalyzer is phosphomolybdic acid.

[0041] Table 3. Reaction time on the results of the alkylation reaction of single-ring aromatic components of heavy aromatics by rectification and styrene

[0042]

[0043] From the above results, it can be seen that with the prolongation of the reaction time, the boiling point composition of the product oil changes significantly. When prolonging the reaction time from 1 to 10 h, the content of components with boiling points at 240-310°C increases slowly, and the content of components with boiling points at 310-365°C increases significantly. Continue to prolong the reaction time to 20h, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com