Method for preparing quick-hardening and early-strength phosphorus-slag-base cementitious materials

A technology of phosphate residue and base glue, applied in the fields of botanical equipment and methods, planting substrates, phosphate fertilizers, etc., can solve the problems of insignificant early-strength effect and slow hardening rate, and achieve excellent fast-hardening and early-strength performance, reducing content, The effect of improving structural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

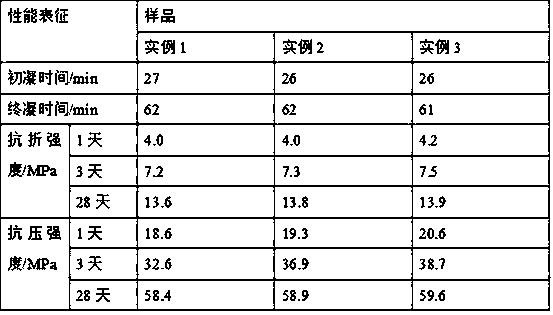

Examples

example 1

[0018] Select phosphate rock slag and place it in a ball mill tank. After ball milling at 200r / min for 3 hours, pass through a 200-mesh sieve to obtain a ball-milled powder. Take moderate saline-alkali soil and grind it through a 100-mesh sieve to obtain a ground powder. The mass ratio is 1:10 , stir and mix the grinding powder with deionized water and let it stand for 6 hours, then centrifuge at 1500r / min and collect the supernatant to obtain the matrix liquid, and weigh 45 parts of the matrix liquid and 45 parts of water respectively in parts by weight , 2 parts of potassium nitrate, 3 parts of magnesium sulfate, and 1 part of calcium nitrate were stirred and mixed and dispersed ultrasonically for 10 minutes to obtain a nutrient solution; in parts by weight, 55 parts of ball mill powder, 10 parts of river sand, 25 parts of sawdust and 10 parts of sawdust were weighed respectively. Place the aluminum slag in a ball mill tank, and pass through a 100-mesh sieve to obtain the cul...

example 2

[0020] Select phosphate rock slag and place it in a ball mill tank. After ball milling at 250r / min for 4 hours, pass through a 200-mesh sieve to obtain a ball-milled powder. Take moderate saline-alkali soil and grind it through a 100-mesh sieve to obtain a ground powder. The mass ratio is 1:10 , stir and mix the grinding powder with deionized water and let it stand for 7 hours, then centrifuge at 1750r / min and collect the supernatant to obtain the matrix liquid. In parts by weight, weigh 47 parts of the matrix liquid and 47 parts of water respectively , 2 parts of potassium nitrate, 4 parts of magnesium sulfate, and 2 parts of calcium nitrate were stirred and mixed and ultrasonically dispersed for 12 minutes to obtain a nutrient solution; in parts by weight, 57 parts of ball mill powder, 12 parts of river sand, 27 parts of sawdust and 12 parts were weighed respectively. Place the aluminum slag in a ball mill tank, and pass through a 100-mesh sieve to obtain the culture substrat...

example 3

[0022]Select phosphate rock slag and place it in a ball mill tank. After ball milling at 300r / min for 5 hours, pass through a 200-mesh sieve to obtain a ball-milled powder. Take moderately saline-alkali soil and grind it through a 100-mesh sieve to obtain a ground powder. The mass ratio is 1:10 , stir and mix the ground powder with deionized water and let it stand for 8 hours, then centrifuge at 2000r / min and collect the supernatant to obtain the matrix liquid. In parts by weight, weigh 50 parts of the matrix liquid and 50 parts of water respectively , 3 parts of potassium nitrate, 5 parts of magnesium sulfate, and 2 parts of calcium nitrate were stirred and mixed and ultrasonically dispersed for 15 minutes to obtain a nutrient solution; Place the aluminum slag in a ball mill tank, and pass through a 100-mesh sieve to obtain the culture substrate; take the vigorously growing bushes of Amarina, Salicornia, and Suaeda salsa in October, collect seeds with better maturity, and rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com