Etching method of grooves in wafer

A technology of grooves and wafers, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of residual, deep groove edge morphology that is easily affected by process fluctuations, etc., and achieves improved yield and is not easy Breakdown, the effect of accelerating the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention as Figure 1-5 shown, including the following steps:

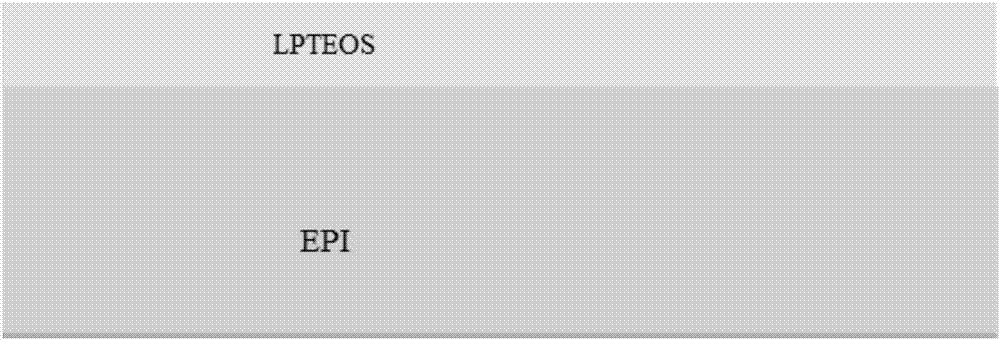

[0032] 1) Deposit a hard mask layer (LPTEOS) on the surface of the silicon body;

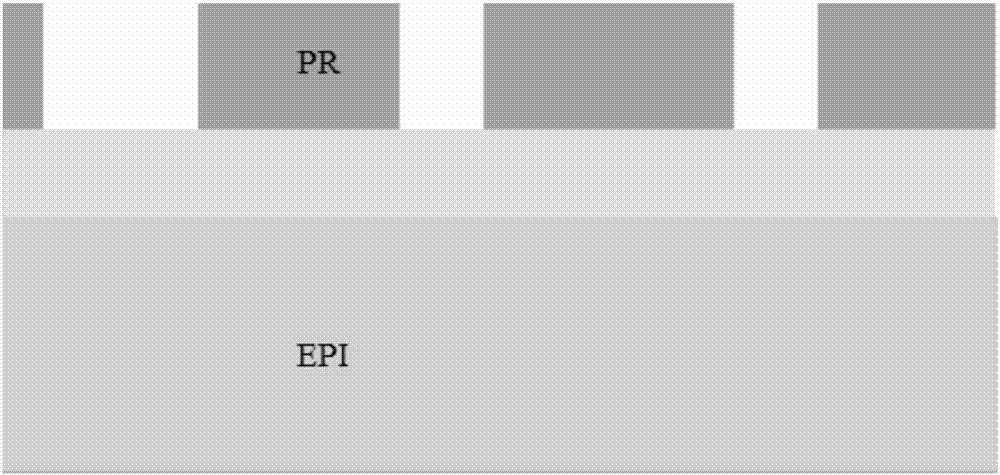

[0033] 2) Make a photomask on the hard mask, and use a protective layer (PR, photomask) to block the places that do not need to be etched;

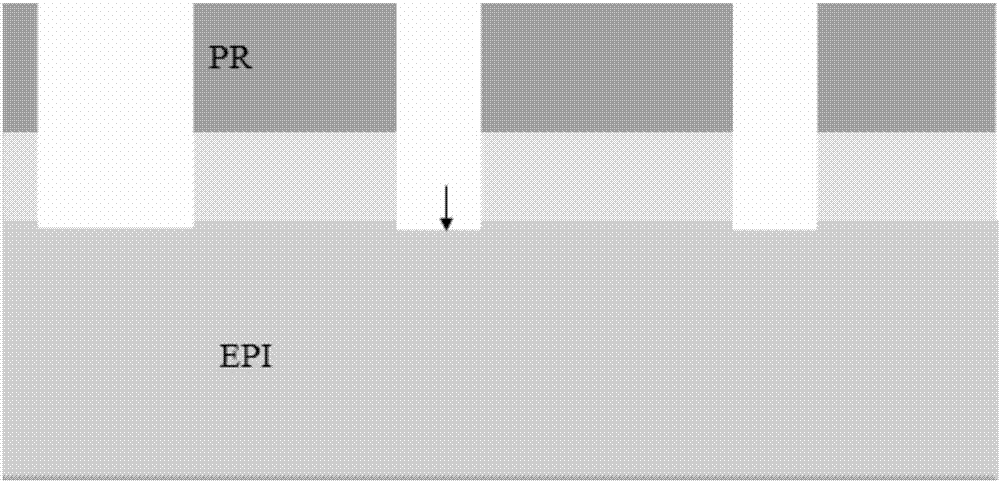

[0034] 3) Etching is performed in the area without the protective layer until the surface of the silicon body (EPI) is exposed;

[0035] 4) Remove the photomask on the surface of the silicon body and clean it to obtain a clean surface;

[0036] 5) Use the hard mask layer as the barrier layer to etch the silicon body to obtain the required deep trench;

[0037] The specific steps of etching the silicon body in the step 5) are:

[0038] 5.1) Remove the natural oxide layer on the surface of the silicon body; a layer of natural oxide layer will be formed after the silicon body is in contact with air, which will reduce the etching efficiency, so it needs to be removed.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com