Heavy load single waveform generator harmonic reducer with ultrashort designed life

A technology of waveform generator and harmonic reducer, which is applied in the field of aerospace, can solve the problems of reducing the payload of aerospace vehicles, large size of harmonic reducer, redundant service life, etc., and achieves the improvement of radial stiffness and axial The effect of compact layout and high torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

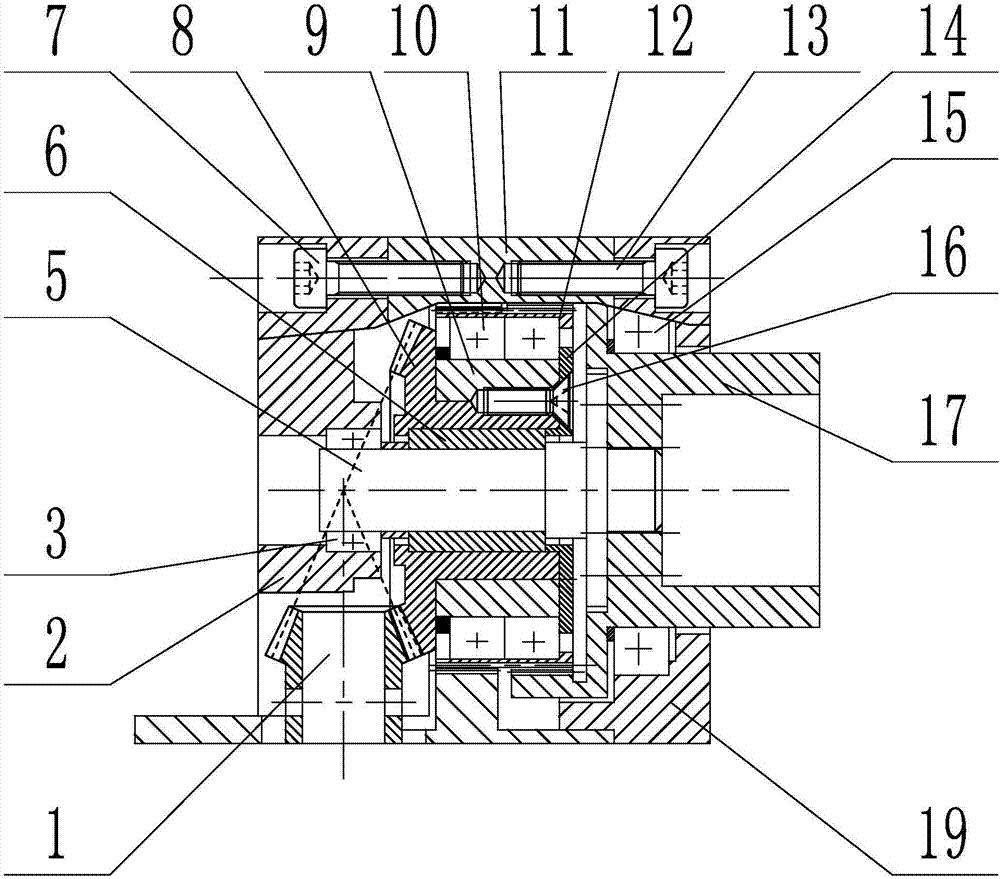

[0013] Specific implementation mode one: combine figure 1 Describe this embodiment, a heavy-duty single waveform generator harmonic reducer with ultra-short design life described in this embodiment includes a small bevel gear 1, a left housing 2, a feedback shaft 5, a large bevel gear 8, and a wave generator 9. Fixed steel wheel 11, flexible spline 12, output shaft 17 and right end cover 19, small bevel gear 1 is vertically arranged inside the left casing 2, small bevel gear 1 is connected with the motor, and feedback shaft 5 is horizontally arranged on the left casing Inside the body 2, the front end of the feedback shaft 5 is rotationally connected with the left housing 2, the rear end of the feedback shaft 5 is fixed horizontally with the output shaft 17, and the outer side of the output shaft 17 is fitted with a right end cover 19, and the output shaft 17 and the right end cover 19 Rotational connection, the outer side of the feedback shaft 5 is equipped with a large bevel...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Describe this embodiment, the first powder metallurgy bearing 6 is provided between the feedback shaft 5 and the large bevel gear 8 in this embodiment, the second powder metallurgy bearing 3 is provided between the front end of the feedback shaft 5 and the left housing 2, A deep groove ball bearing 15 is provided between the output shaft 17 and the right end cover 19 . Other compositions and connection methods are the same as those in Embodiment 1.

[0017] The feedback shaft 5 and the wave generator assembly are supported by the first powder metallurgy bearing 6, the second powder metallurgy bearing 3 at the front end of the feedback shaft 5 and the deep groove ball bearing 15 on the output shaft 17 serve as the support for the entire harmonic drive system.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 This embodiment will be described. The eccentricity between the inner circle and the outer circle of the wave generator 9 in this embodiment is 0.14 mm. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

[0019] In this embodiment, the material of the wave generator 9 is 40Cr, which is an eccentric ring, and the wave generator 9 is installed on the large bevel gear 8 to form an eccentric disc single wave generator assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com